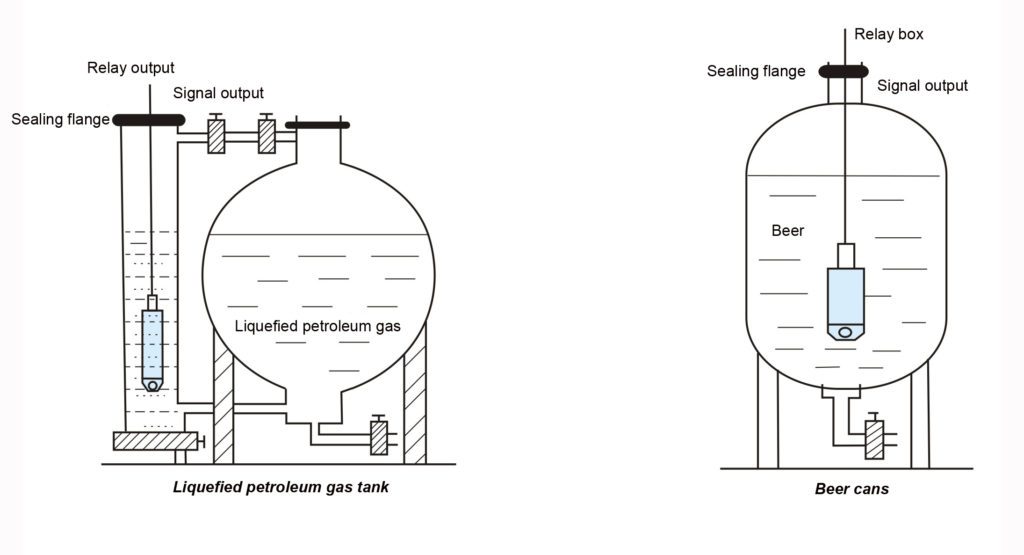

Submersible level transmitters have become an essential tool in various industrial applications. These devices are specifically designed to measure liquid levels in tanks, wells, and other submerged environments. Their ability to withstand harsh conditions, such as high pressure and extreme temperature, makes them reliable and durable in demanding industrial settings. In this comprehensive guide, we will explore the key aspects of submersible level transmitters, including their working principle, installation process, and the important features to consider when choosing the right transmitter for your specific industrial application.

What is a submersible level transmitter?

A submersible level transmitter, also known as a hydrostatic level transmitter, is a device used to measure the level of liquids in tanks or wells. It consists of a sensing element, which is typically a pressure sensor, and a housing that protects the sensor from the surrounding liquid. The sensing element detects the pressure exerted by the liquid and converts it into an electrical signal, which is then transmitted to a control system for further processing. The housing is designed to be waterproof and corrosion-resistant, allowing the transmitter to operate reliably even in submerged conditions.

Submersible level transmitter working principle

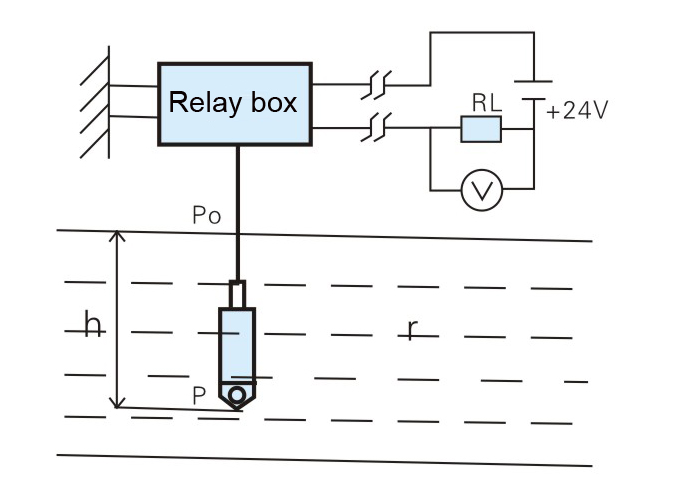

The working principle of a submersible level transmitter is based on the hydrostatic pressure exerted by the liquid being measured. As the level of the liquid increases, the pressure at the bottom of the tank or well also increases. This pressure is sensed by the pressure sensor inside the transmitter. The sensor converts the pressure into an electrical signal, which is proportional to the liquid level. The electrical signal is then sent to a control system, where it can be displayed, recorded, or used for further control purposes.

Submersible level transmitter installation

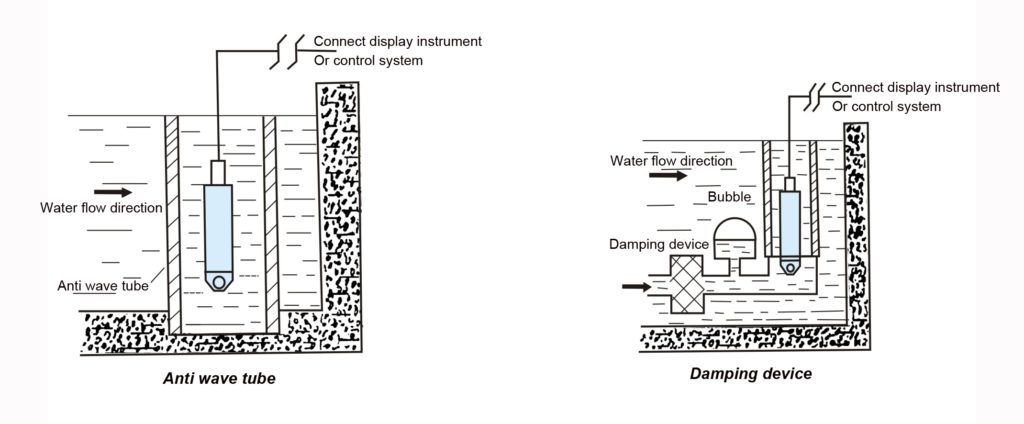

If the submersible liquid level transmitter needs to be installed in a static deep well or pool, the usual practice is to fix the steel pipe with an inner diameter of about φ45mm (a number of small holes at different heights so that the water can enter the pipe smoothly) in the water, and then the submersible liquid level transmitter is fixed in the water. The liquid level transmitter can be used by putting it into the steel pipe.

When the submersible liquid level transmitter measures the liquid level of flowing or agitated liquids, usually a steel pipe with an inner diameter of about φ45mm (a number of small holes are punched at different heights on the opposite side of the liquid flow direction, so that the water can enter the pipe smoothly) is fixed in the water, and then Put the submersible level transmitter into the steel pipe and it can be used. It can effectively reduce the influence of the pressure difference of the water flow on the measurement.

The installation direction of the submersible liquid level transmitter is vertical, and the submersible installation position should be far away from the liquid inlet and outlet and the agitator.

When the submersible level transmitter is used with large vibration, a steel wire can be wrapped around the transmitter, and the steel wire can be used for shock absorption, so as to avoid breaking the cable. Turn off the power supply, stop using it, and check the power supply. When connecting the power supply, it should be connected in strict accordance with our company’s wiring instructions. Avoid the pressure directly impacting the probe when the liquid flows down, or use other objects to block the immediate impact pressure when the liquid flows down.

Try to stay away from high-power equipment, avoid the influence of strong magnetic field interference on accuracy, and keep the level gauge within the normal temperature range, otherwise it will seriously affect the accuracy and service life of the submersible level transmitter, resulting in a long-term temperature drift phenomenon. It may directly burn out the submersible level transmitter.

Key features to look for in a submersible level transmitter

When choosing a submersible level transmitter for your industrial application, there are several key features to consider to ensure optimal performance and reliability. Firstly, it is important to select a transmitter that is suitable for the specific liquid being measured. Different liquids may require different materials for the housing and sensing element to resist corrosion and ensure long-term durability. Secondly, the accuracy and resolution of the transmitter are critical factors to consider. The transmitter should be capable of providing precise and consistent measurements within the required range. Additionally, features such as temperature compensation, self-cleaning mechanisms, and built-in diagnostics can greatly enhance the functionality and performance of the transmitter.

Conclusion and final thoughts on choosing the right submersible level transmitter for your industrial application

Choosing the right submersible level transmitter for your industrial application is a decision that should not be taken lightly. By understanding the working principle, installation process, and key features of submersible level transmitters, you can make an informed decision that meets the specific requirements of your application. It is essential to consider factors such as durability, accuracy, and compatibility with the liquid being measured. By selecting a high-quality submersible level transmitter, you can ensure reliable and accurate level measurement, leading to improved efficiency and productivity in your industrial processes.

In conclusion, submersible level transmitters are invaluable tools in various industrial applications. Their ability to withstand harsh conditions and accurately measure liquid levels make them essential in ensuring efficient and reliable processes. By following the guidelines provided in this guide, you can confidently select the right submersible level transmitter for your industrial application, knowing that you are making a well-informed decision based on the specific requirements of your operation. Choose wisely and experience the benefits of accurate and reliable level measurement in your industrial processes.

CTA: Contact us today to learn more about our range of submersible level transmitters and how they can enhance your industrial processes.