3051 Pressure transmitter, also known as rosemount pressure transmitter which is a type of capacitance type pressure transmitter solutions. The pressure transmitter is a device that converts the electrical signal from the transducer into a much larger electrical signal that can be sent over a long distance to a PLC or a DCS. The rosemount transmitter are most common and useful industrial pressure measuring instrument.

pressure transducer vs transmitter

In a pressure transducer, a thin-film or piezo-resistive pressure sensor is mounted on a process connection. The transducer converts pressure into an analog electronic output signal, typically as a millivolt per volt output. These signals are not linearized or temperature compensated.

A pressure transmitter has additional circuitry that linearizes, compensates, and amplifies the signal from a transducer. The different signal types are typically voltage signals (e.g., 0 to 5 or 0 to 10 volts), milliamp (e.g., 4 to 20 milliamp), or digital. The instrument then can transmit the signal to a remote receiver.

Many pressure transmitters with digital display offer a variety of calibration options, including turndown and zero/span adjustment. Smart transmitters can be calibrated, tested, and reset remotely using a bus network.

For more details you can read the wika pressure transmitter supplier article

differential pressure transmitter working principle

Differential pressure transmitter manifold design works on the principle of differential capacitance. In this design, the sensing element is a taut metal diaphragm located equidistant between two stationary metal surfaces, comprising three plates for a complementary pair of capacitors. An electrically insulating fill fluid (usually a liquid silicone compound) transfers motion from the isolating diaphragms to the sensing diaphragm, and also doubles as an effective dielectric for the two capacitors. Any difference of pressure across the cell causes the diaphragm to flex in the direction of least pressure. The sensing diaphragm is a precision-manufactured spring element, meaning that its displacement is a predictable function of applied force. So the diaphragm’s secondary function as one plate of two capacitors provides a convenient method for measuring displacement. Since capacitance between conductors is inversely proportional to the distance separating them, capacitance on the low-pressure side will increase while capacitance on the high-pressure side will decrease.

SenTec designed various types of pressure transmitter for liquids or gases, like water pressure transmitter, steam pressure transmitter, gas pressure transmitter, natural gas pressure transmitter etc. They are are ideal replacement of rosemount pressure transmitter 3051 with excellent linearity and performance over temperature, long, reliable service life.

Read more: how do differential pressure transmitters work?

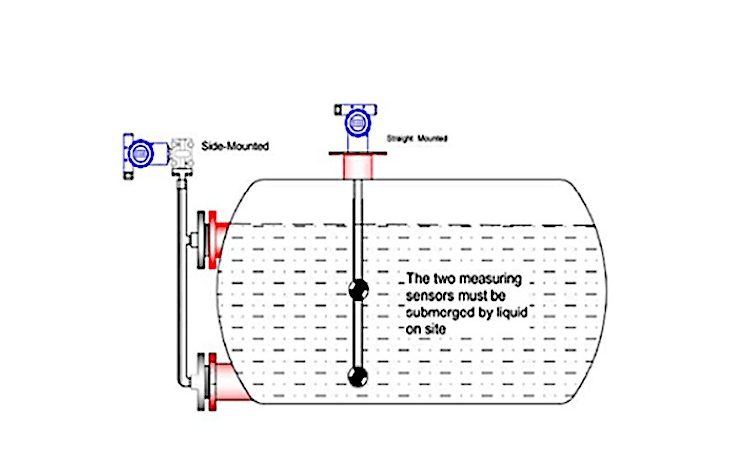

Differential pressure type level transmitter

The liquid pressure transmitter used to measure the level can designed with single flange and double flange.

1. The single flange is used to measure the liquid level of the open tank.

Differential pressure range calculation method: need to measure the liquid level height (unit: m) × gravity acceleration (9.8) × measured medium density (unit: g / cm3, when the density of water is calculated as 1, the unit is g / cm3) Range (unit: KPa).

The type selection must know the measuring medium, measuring range, medium temperature, process connection flange size and pressure rating and flange standard.

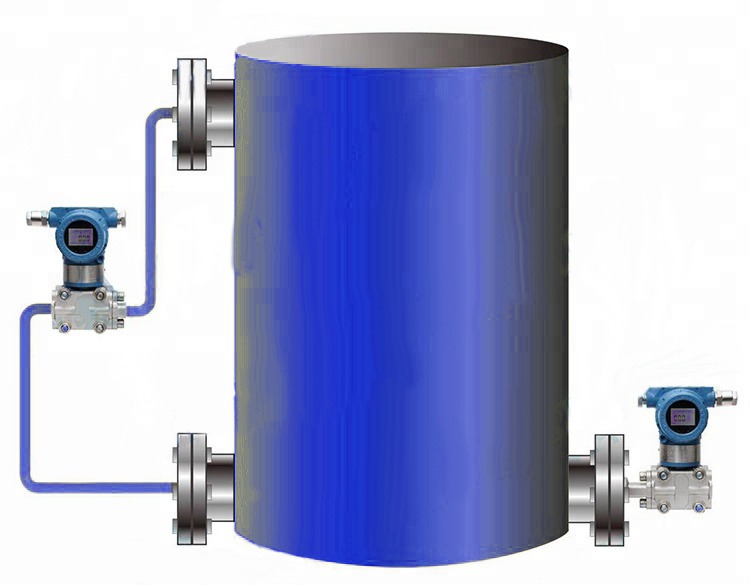

2. Double flange is used to measure the liquid level of the closed tank.

Differential pressure range calculation method: need to measure liquid level height (unit: meter) × gravity acceleration (9.8) × (measured medium density-capillary filling liquid density) (unit: g / cm3) = differential pressure range (unit: KPa ).

The type selection must know the measurement medium, measuring range, medium temperature, pressure, capillary length, process connection flange size and pressure rating, and flange standard.

The typical application is boiler drum level measurement by differential pressure transmitter.

differential pressure transmitter for flow measurement

From the working principle of the differential pressure flow transmitter: the differential pressure flow transmitter can calculate the pipeline flow by measuring the pressure difference between the two ends of the throttle device. The differential pressure transmitter measures the flow rate, which is mainly connected to the two holes perpendicular to the flow axis of the throttling device through the hose. What they sense is the static pressure difference between the two sections. By the principle of energy conservation, the duct static pressure transmitter two sections difference is approximately equal to the dynamic pressure difference between the two sections. Because the dynamic pressure is proportional to the square of the flow velocity, the flow velocity is inversely proportional to the square of the diameter of the over-flow section. Therefore, by measuring the static pressure difference between the two sections, the flow velocity and flow rate of the section can be obtained.

Application of differential pressure flow transmitter in steam metering system

The differential pressure flow transmitter measures the flow rate and needs to be used in conjunction with the orifice flowmeter and flow totalizer. Indispensable. There are two pressure pipes on the orifice flowmeter, and these two pressure pipes are connected to the high and low pressure chambers of the differential pressure transmitter. The measured flow is that water is flowing, so there will be direction and flow size. The differential pressure transmitter measures the differential pressure at two points. Output analog signal to flow totalizer to accumulate flow.

Read more: how the DP flow meter works?

differential pressure transmitter for density measurement

For differential pressure transmitters: differential pressure △ P = density hundred ρ × liquid level height h × gravity acceleration g

When measuring the liquid level, ρ and g are constants, and △ P is a function of h;

If h and g are constants, ΔP is a function of ρ. You can measure the density;

The specific method is to connect the positive and negative pressure of the transmitter to the liquid level (h is a fixed value), and the measured differential pressure is related to the density.

Note that in order to keep the liquid density in the pressure tube unchanged (otherwise it will affect the measurement results), it is usually necessary to fill the pressure tube with isolation liquid.