In industrial temperature monitoring, precision is of utmost importance. Accurate temperature Type J Thermocouple measurements can make a significant difference in various applications, from ensuring product quality to maintaining optimal operating conditions. One technology that plays a crucial role in achieving accurate temperature readings is the thermocouple. Thermocouples are widely used in industrial settings due to their reliability and versatility. In this article, we will demystify one specific type of thermocouple: the Type J thermocouple.

Understanding the basics of thermocouples

Before diving into Type J thermocouple, it is essential to understand the basics of thermocouples. A thermocouple is a temperature sensor that operates based on the principle of the Seebeck effect. This effect states that when two dissimilar metals are joined at two points, a voltage is generated when there is a temperature gradient between the two points. This voltage is directly proportional to the temperature difference and can be measured to determine the temperature accurately.

What is a Type J thermocouple?

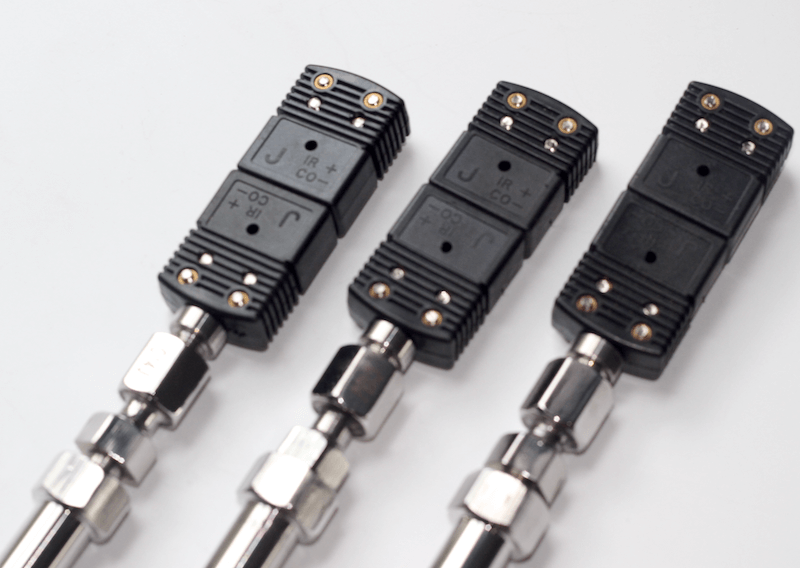

A Type J thermocouple is a specific type of thermocouple that consists of an iron (Fe) positive leg and a constantan (CuNi) negative leg. The positive leg of the thermocouple, made of iron, provides stability and durability, while the negative leg, made of constantan, offers a wide temperature range and excellent resistance to oxidation. The combination of these two metals results in a thermocouple that is suitable for a range of industrial applications.

Type J thermocouples are known for their high accuracy and reliability, making them a popular choice in industries where precise temperature monitoring is essential. These thermocouples can measure temperatures ranging from -210°C to 1200°C (-346°F to 2192°F), providing a wide operating range for various industrial processes.

Advantages and disadvantages of Type J thermocouple

Type J thermocouple offers several advantages that make them a preferred choice in many industrial settings. One of the significant advantages is their high accuracy, especially in the lower temperature range. They also have a relatively low cost compared to other thermocouple types, making them a cost-effective solution for temperature measurement.

However, Type J thermocouple does have some limitations. They are susceptible to corrosion and can degrade rapidly in the presence of certain chemicals and gases. Additionally, they have a relatively low maximum temperature range compared to some other thermocouple types. Despite these limitations, Type J thermocouples are widely used in industries such as food processing, HVAC, and pharmaceuticals.

Type J thermocouple wire: composition and characteristics

The composition of the wire used in Type J thermocouples plays a crucial role in their performance and accuracy. As mentioned earlier, a Type J thermocouple consists of an iron positive leg and a constantan negative leg. The positive leg, made of iron, provides stability and durability, while the constantan negative leg offers excellent resistance to oxidation and a wide temperature range.

The wire used in Type J thermocouples is typically insulated with a protective sheath to shield it from external influences. The sheath material can vary depending on the application requirements, with options such as stainless steel, Inconel, and ceramic available. The choice of sheath material depends on factors such as temperature range, chemical resistance, and mechanical durability.

Type J thermocouple range and applications

Type J thermocouples have a wide temperature range, making them suitable for various industrial applications. They can accurately measure temperatures ranging from -210°C to 1200°C (-346°F to 2192°F). This wide operating range allows Type J thermocouples to be used in industries such as food processing, HVAC, pharmaceuticals, and many more.

In the food processing industry, Type J thermocouples are commonly used to monitor temperatures in ovens, grills, and refrigerators. Their accuracy and reliability make them ideal for ensuring proper food safety and quality.

In HVAC systems, Type J thermocouples are utilized for temperature monitoring in heating and cooling systems. They help maintain optimal temperatures for comfortable indoor environments.

In the pharmaceutical industry, Type J thermocouples are employed to monitor temperatures in laboratories, research facilities, and manufacturing processes. Accurate temperature control is critical in pharmaceutical settings to ensure the efficacy and safety of drugs.

Type J vs Type K thermocouples: a detailed comparison

While Type J thermocouples have their advantages, it is essential to compare them with other thermocouple types to make an informed decision. One common comparison is between Type J and Type K thermocouples.

Type K thermocouples are one of the most popular thermocouple types, offering a wide temperature range and excellent resistance to corrosion. However, they have a slightly lower accuracy compared to Type J thermocouples, especially in the lower temperature range. Type J thermocouples, on the other hand, provide higher accuracy at lower temperatures but have a lower maximum temperature range.

The choice between Type J and Type K thermocouples depends on the specific requirements of the application. If high accuracy at lower temperatures is crucial, Type J thermocouples are the preferred choice. If a wider temperature range and better corrosion resistance are more critical, Type K thermocouples may be the better option.

Type J thermocouple chart: temperature and voltage relationship

To understand the relationship between temperature and voltage in Type J thermocouples, a Type J thermocouple chart can be used as a reference. This chart provides a graphical representation of the voltage generated by a Type J thermocouple at different temperatures.

The Type J thermocouple chart shows that as the temperature increases, the voltage output also increases. This relationship is not linear but follows a specific curve. By referring to the chart, temperature measurements can be accurately determined based on the corresponding voltage readings.

Using the Type J thermocouple chart, operators can ensure precise temperature monitoring and make informed decisions regarding process control and adjustments.

Choosing the right Type J thermocouple for your application

Selecting the right Type J thermocouple for a specific application is crucial to achieve accurate temperature measurements. Several factors should be considered when choosing a Type J thermocouple, including the temperature range, chemical environment, sheath material, and response time requirements.

First, determine the temperature range that the thermocouple will be exposed to. Ensure that the selected Type J thermocouple can handle the minimum and maximum temperatures required for the application.

Next, consider the chemical environment in which the thermocouple will be used. Some chemicals can cause rapid degradation of the thermocouple wire, affecting its accuracy and lifespan. Choose a Type J thermocouple with appropriate sheath material that can withstand the chemical environment.

Response time is another critical factor to consider. If the application requires fast temperature response, select a Type J thermocouple that has a quick response time.

By carefully considering these factors, the right Type J thermocouple can be chosen to ensure accurate and reliable temperature measurements in the specific industrial application.

SenTec as the type J thermocouple manufacturer provide various types of thermocouples.

Type J thermocouple wire color code and identification

To identify Type J thermocouples easily, a color code is used for the thermocouple wires. The color coding follows a standard that helps operators and technicians identify the type of thermocouple without confusion.

In the case of Type J thermocouples, the positive leg (iron) is color-coded as white, while the negative leg (constantan) is color-coded as red. This color combination makes it easy to distinguish Type J thermocouples from other thermocouple types.

Following the color code is crucial during installation, maintenance, and troubleshooting of Type J thermocouples to ensure correct wiring and accurate temperature measurements.

Common misconceptions about Type J thermocouples

Like any technology, there are common misconceptions associated with Type J thermocouples. One common misconception is that Type J thermocouples are not suitable for high-temperature applications. While it is true that Type J thermocouples have a lower maximum temperature range compared to some other thermocouple types, they can still handle temperatures up to 1200°C (2192°F), which is sufficient for many industrial applications.

Another misconception is that Type J thermocouples are prone to rapid degradation due to corrosion. While it is true that they can be susceptible to certain chemical environments, proper selection of sheath material can minimize the impact of corrosion. Additionally, regular maintenance and inspection can help identify and mitigate any potential degradation issues.

It is important to address these misconceptions to ensure that Type J thermocouples are not overlooked or dismissed based on inaccurate information.

Type J thermocouple maintenance and troubleshooting

Proper maintenance and troubleshooting are essential to ensure the continued accuracy and reliability of Type J thermocouples. Regular inspection of the thermocouple, including the sheath and wiring, can help identify any signs of degradation or damage.

Cleaning the thermocouple regularly is also crucial, especially in applications where the thermocouple is exposed to contaminants. Use appropriate cleaning methods and materials to avoid further damage to the thermocouple.

In case of any temperature measurement discrepancies or anomalies, troubleshooting can help identify the root cause of the issue. This may involve checking the wiring connections, verifying the calibration, or examining the environmental factors that could affect the thermocouple’s performance.

By conducting regular maintenance and troubleshooting, operators can ensure that Type J thermocouples continue to provide accurate temperature measurements and minimize any potential disruptions to the industrial processes.

Conclusion: Why Type J thermocouples are essential for precise temperature monitoring in industrial settings

In industrial temperature monitoring, precision is vital to ensure product quality, process efficiency, and operational safety. Type J thermocouples play a crucial role in achieving this precision. Their high accuracy, reliability, and wide temperature range make them an essential tool in various industries.

By understanding the basics of thermocouples, the composition and characteristics of Type J thermocouples, and their advantages and limitations, operators can make informed decisions regarding temperature monitoring in industrial settings. Proper selection, installation, and maintenance of Type J thermocouples can ensure accurate and reliable temperature measurements, leading to improved process control and optimization.

In conclusion, Type J thermocouples are the key to precision in industrial temperature monitoring. Their ability to provide accurate measurements across a wide temperature range makes them an invaluable asset in industries where temperature control is critical. By harnessing the power of Type J thermocouples, industrial processes can operate with greater efficiency, reliability, and safety.

CTA: If you are looking for precise and reliable temperature monitoring in your industrial setting, consider incorporating Type J thermocouples into your systems. Contact our experts today to learn more about how Type J thermocouples can enhance your temperature measurement capabilities.