The mass flowmeter directly measures the mass flow of the medium passing through the flowmeter, and can also measure the density of the medium and indirectly measure the temperature of the medium.

What is a Mass Flow Meter?

Mass flow meter directly measures the mass flow of the medium passing through the flow meter. It can also measure the density, temperature and viscosity of the medium. Mass flow meter is a flow measuring instrument that measures the mass flow in the pipeline. The volume of a fluid is a function of fluid temperature and pressure and is a dependent variable. The quality of a fluid is a quantity that does not change with time, space temperature, and pressure.

5 common Mass Flow Meter Types

Mass flow meters can be divided into two categories: one is direct type, which directly outputs mass flow; the other is indirect type or derivation type, such as the combination of ultrasonic flowmeter and density meter, and their output is multiplied to obtain Get the mass flow.

1. Direct: There are many types of direct mass flow meters, such as calorimetric, angular momentum, gyro, and double impeller. This kind of instrument is suitable for measuring small flow of gas, but the disadvantage is that it is inert, the measured value is related to the constant pressure specific heat of the gas, and the measuring element is in contact with the medium and is easily contaminated and corroded.

2. Indirect: There are 3 main types of indirect mass flow meters: a combination of a velocity flow meter and a density meter, a combination of a throttling (or target) flowmeter and a volumetric flowmeter, and a throttling (or target) flowmeter. Type) flowmeter and density meter combination.

3. Thermal: The basic principle of thermal mass flowmeter is to use an external heat source to heat the fluid to be measured in the pipeline. Mass Flow.

4. Differential pressure type: Differential pressure type mass flowmeter is a flowmeter based on the Magnus effect. In practical applications, the combination of orifice plate and quantitative pump is used to achieve mass flow measurement. There are two common structures of double-hole plate and four-hole plate combined with quantitative pump. \Coriolis

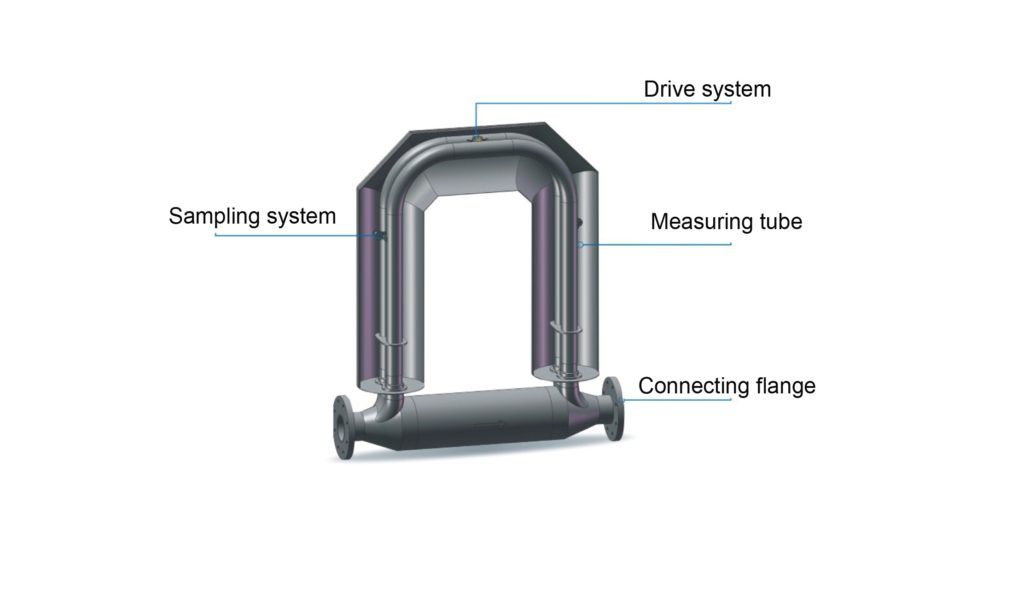

5. Coriolis: Coriolis mass flowmeter (referred to as Coriolis force flowmeter) is a direct measurement method that utilizes the principle of Coriolis force proportional to mass flow generated by fluid flowing in a vibrating tube. Mass flow meter.

Mass Flow Meter Working Principle

The mass flowmeter adopts sensible heat measurement, and the flow rate is measured by the molecular mass carried away by the split molecules. Because it is a sensible heat measurement, it will not affect the measurement results due to changes in gas temperature and pressure.

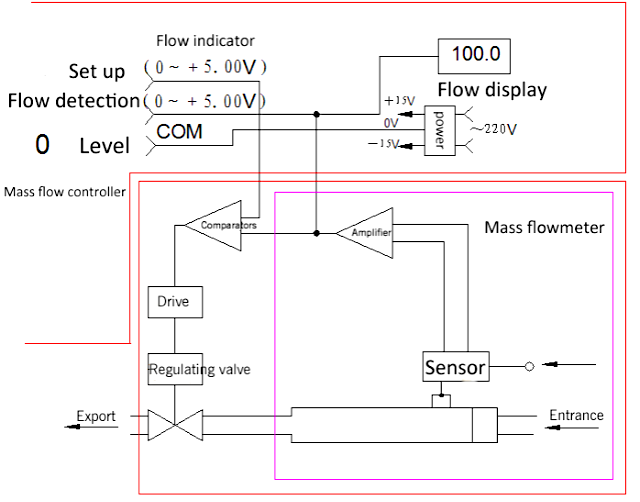

MFC Mass Flow Controller Working Principle:

Mass flow controller (MFC for short), the sealed probe consists of two sensing elements-speed sensor and temperature sensor, which can automatically correct the influence of temperature and pressure changes. The meter circuit heats the speed sensor to a constant value higher than the gas temperature, and then measures the cooling effect of the gas flow. The flow rate is calculated by measuring the electric power consumed to maintain a constant temperature difference proportional to the mass flow rate of the gas.

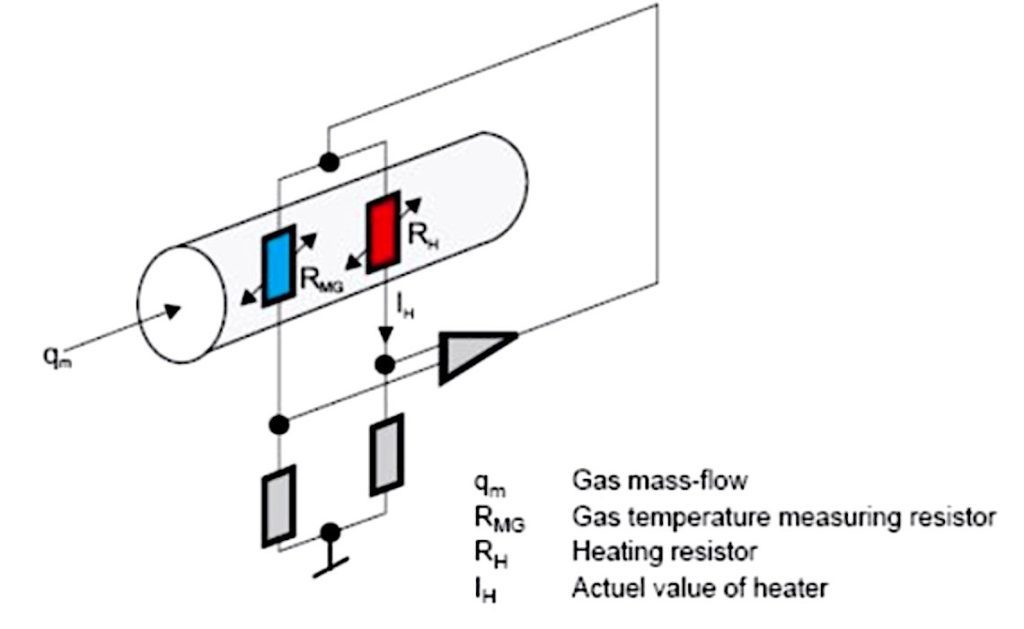

Thermal gas mass flow meter working principle:

Thermal gas mass flow meters are instruments that measure gas flow using the principle of thermal diffusion. The sensor consists of two reference-grade resistance thermal resistors (RTDs). One is a speed sensor RH, and the other is a temperature sensor RMG that measures the change in gas temperature. When these two RTDs are placed in the measured gas, the sensor RH is heated, and the other sensor RMG is used to sense the measured gas temperature. As the gas flow rate increases, more heat is removed by the gas flow and the temperature of the sensor RH decreases.

Coriolis force flow measurement principle:

The Coriolis effect, referred to as the Coriolis force, is a description of the offset of the linear motion of a mass point in a rotating system due to inertia relative to the linear motion of the rotating system. Mass flowmeter is a typical application of Coriolis force. It allows the fluid to be measured to pass through a vibrating measuring tube. The flow of the fluid in the pipeline is equivalent to linear motion. The vibration of the measuring tube will generate an angular velocity. Driven by an external electromagnetic field, it has a fixed frequency, so the Coriolis force of the fluid in the pipeline is only related to its mass and velocity, and the product of mass and velocity, that is, the flow velocity, is the mass flow that needs to be measured. The Coriolis force of the fluid in the pipe can measure its mass flow.

Mass flow meter VS mass flow controller

*Mass flowmeter adopts sensible heat measurement, and the flow rate is measured by the molecular mass carried away by the split molecules. Because it is a sensible heat measurement, it will not affect the measurement results due to changes in gas temperature and pressure. Mass flowmeter is a relatively accurate, fast, reliable, efficient, stable and flexible flow measurement instrument, which will be more widely used in petroleum processing, chemical and other fields. Mass flowmeter cannot control flow, it can only detect liquid Or mass flow of gas, output flow value through analog voltage, current or serial communication.

*Mass flow controllers are instruments that can detect and control at the same time. In addition to the measurement part, the mass flow controller itself also has an electromagnetic regulating valve or a piezoelectric valve, so that the mass flow control itself constitutes a closed-loop system for controlling the mass flow of the fluid. The setting value of the mass flow controller can be provided by analog voltage, analog current, or computer and PLC.

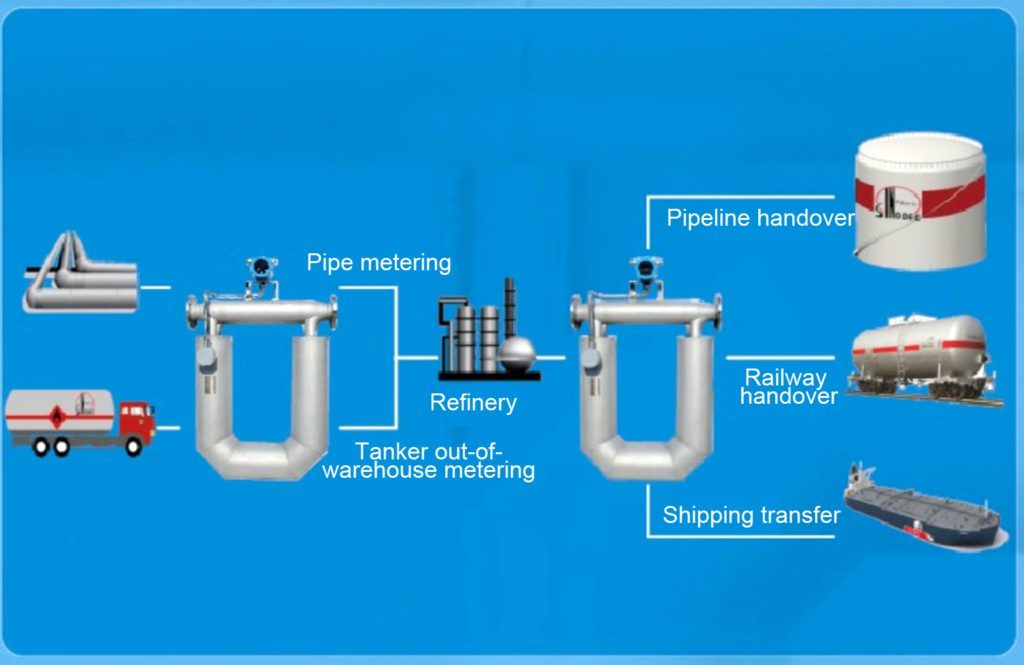

Mass flow meter application

Applications of MFC mass flow meter controller:

MFC mass flow controller, also called mass flow meter is used for precise measurement and control of the mass flow of gas or liquid. They play an important role in scientific research and production in the fields of semiconductor and integrated circuit industry, special materials, chemical industry, industry, medicine, environmental protection and vacuum lamps. Typical applications include: electronic process equipment, such as diffusion, epitaxy, CVD, oxidation, plasma etching, sputtering, ion implantation; and coating equipment, optical fiber melting, micro-reaction device, mixed gas distribution system, capillary measurement Gas chromatograph and other analytical instruments.

Applications Thermal gas mass flow meters:

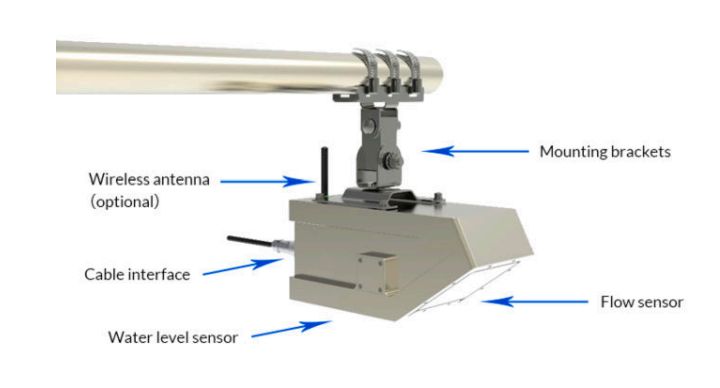

Thermal gas mass flow meters are divided into: plug-in type and pipe segment type according to the installation method.

*The plug-in thermal gas mass flowmeter can be installed and maintained online. The plug-in thermal gas flow sensor is suitable for pipe diameter: DN80~6000mm.

*The pipe segment thermal gas mass flowmeter has been equipped with a process pipeline with the same inner diameter as the field pipeline when it leaves the factory. The connection with the field pipeline is flange connection or threaded connection. The pipe section type thermal gas sensor is suitable for pipe diameter: DN15~2000mm.

Thermal gas mass flow applicable medium: all gases compatible with stainless steel. For example, pipeline gas; general systems; biogas; coal gas; natural gas; liquefied gas; boiler preheating air, energy exchange; well filling gas recovery; Gas quality analysis; leak gas testing; natural gas measurement; flare gas monitoring, etc.

Applications of Thermal gas mass flow meters:

Coriolis Flow Meter is mainly used to measure the mass flow and total volume and density of the medium. At the same time, it can also measure the volume flow and total volume, the temperature of the medium, the water content, the alcohol content of alcohol, and the concentration of two liquids that are more uniformly mixed. , The ratio of raw materials in the process flow, etc.Coriolis mass flowmeter realizes the direct measurement of mass flow, has the characteristics of high precision, can measure multiple media and multiple process parameters, and is widely used in petrochemical, pharmaceutical, food and other industries.

Note: As one of the earliest flow meter manufacturer, SenTec provide a wide variety flow measurement solutions, such as differential pressure flow meters, Calorimetric Flowmeter, liquid flow sensor, Ultrasonic Level Transmitter, mass flow meter, Variable Area Flowmeter or Rotameter, Electromagnetic Flowmeter, Turbine Flowmeter, Vortex Flow Meter, Thermal Flowmeter, Coriolis Flowmeter, Mass Flowmeters, Open Channel Flowmeters etc.