What Is ultrasonic level?

Ultrasonic Level Sensing is a low-cost liquid level measurement technology. Ultrasonic Level Sensing sensors and transmitters are used for tank or river level measurement. Ultrasonic Level Sensing does not need to contact the medium, can be continuously measured, low cost. Therefore, Ultrasonic Level Sensing is very popular among users. Ultrasonic liquid level sensors are available in general and intrinsically safe types. Output 4~20mA standard signal or output the measurement result to the secondary meter through RS-485. Meets the system’s automatic control.

What is ultrasonic liquid level sensor?

Ultrasonic liquid level meter, also known as ultrasonic liquid level sensor measuring instrument, is a non-contact, high reliability, cost-effective, easy to install and maintain level measuring instrument. It meets most liquid level measurement requirements without touching the medium. Measures liquids and solids as well as powders and is ideal for challenging corrosives, coatings and waste liquids.

How does ultrasonic level sensor works ?

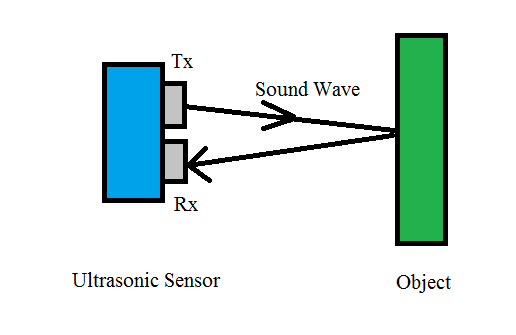

The working principle of the ultrasonic level gauge is that the ultrasonic transducer (probe) sends out a high-frequency pulse. The sound wave encounters the surface of the measured material level (material) and is reflected and folded back. The reflected echo is received by the transducer and converted into an electrical signal. The propagation time of the sound wave is proportional to the distance from the sound wave to the surface of the object. The relationship between the sound wave transmission distance S and the sound speed C and the sound transmission time T can be expressed by the formula: S=C×T/2.

Can ultrasonic sensor detect water level?

Ultrasonic liquid level sensor can be used for water level measurement. The principle of ultrasonic reflection used. According to the contact between the sound wave emitted by the pool ultrasonic liquid level gauge and the liquid surface. According to the length of time it reflects back. To measure the height of the liquid level in the tank.

Liquid level sensors are used in many sites to detect some conditions that require liquid level monitoring. It is well known that the liquid level of some sewage treatment tanks, the liquid level on the tank, the liquid level on the river channel and so on.

What are the Ultrasonic Level Sensor Advantages and Disadvantages ?

Ultrasonic transmitters are divided into general ultrasonic transmitters (without meter head) and integrated ultrasonic transmitters. Integrated ultrasonic transmitters are more commonly used.

The integrated ultrasonic transformer is composed of a meter head (such as an LCD display) and a probe. This kind of transmitter that directly outputs a 4-20mA signal is to assemble a miniaturized sensitive element (probe) and an electronic circuit, thereby Make it smaller, lighter and cheaper. Ultrasonic transmitters can be used for liquid level. Level measurement and open channel, open channel and other flow measurement, and can be used to measure distance.

Then, what are the advatages of a ultrasonic level sensor ?

The advantages of ultrasonic liquid level gauge are very outstanding. As a Ultrasonic level sensor adopt non-contact measurement. It is not easily affected by the viscosity and density of the liquid. The ultrasonic level transmitter completely solves the shortcomings of traditional measurement methods such as rotary, pressure, capacitive, float, etc., such as sticky lotus, entanglement, blockage, leakage, medium corrosion, and inconvenient maintenance.

Of course, the ultrasonic liquid level gauge also has its own limitations and insurmountable defects. Specifically, it is mainly manifested in:

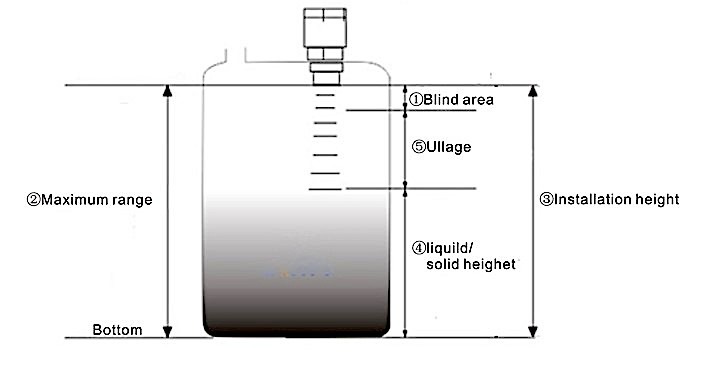

1.There is a blind spot in the ultrasonic liquid level measurement. The dead zone is the area where the meter cannot measure. During the transmission of ultrasonic pulses, a small area near the ultrasonic transducer usually cannot receive sound waves. The blind zone where sound waves cannot be received is related to the measurement distance of ultrasonic waves. Generally speaking, the smaller the measurement distance, the smaller the blind zone. The larger the measurement distance, the larger the blind zone;

Ultrasonic liquid level measurement is easily affected by temperature. In the actual measurement, the change of temperature will cause the change of sound speed. This will lead to errors in the measurement;

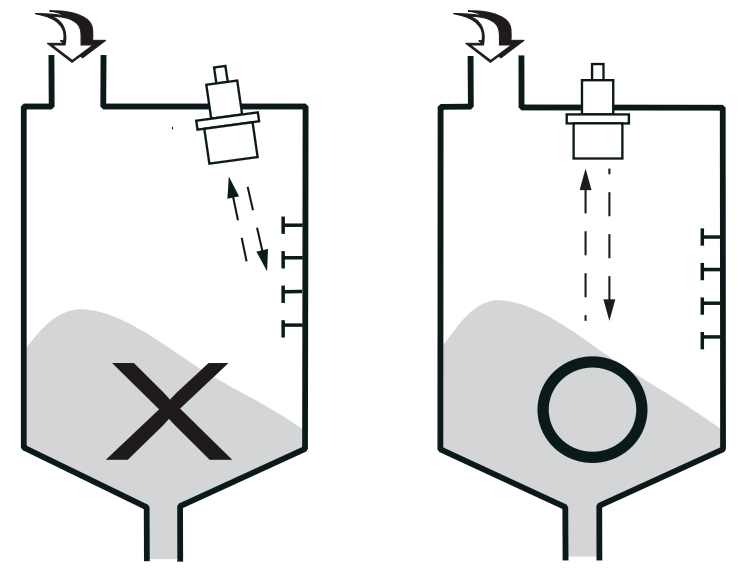

2. There should be no obstacles under the sound wave. Because the ultrasonic liquid level meter uses the principle of sound wave reflection to achieve liquid level measurement. If there are obstacles, it will affect the ultrasonic emission, causing signal loss and affecting the measurement effect;

3. Ultrasonic liquid level gauge should not be used to measure pressure vessels. Because the pressure mainly affects the probe. There is also a certain relationship between the pressure and the temperature. The change in pressure will affect the change in temperature. This will affect the change in the speed of sound. The accuracy of the measurement will be affected;

4. Ultrasonic liquid level gauge can not be used in the occasions with water mist, medium that is easy to produce a lot of foam, and volatile medium. Because this kind of working condition is easy to absorb the sound wave or interfere with the sound wave emission, the signal is lost and the accuracy is reduced;

5. Ultrasonic liquid level gauge is greatly affected by dust. This is because although the dust environment has little effect on the speed of sound, it has a very significant effect on the attenuation of sound waves. Therefore, it is best not to use an ultrasonic level gauge in the presence of dust.

Ultrasonic liquid level sensor application

Ultrasonic liquid level sensor is a digital liquid level meter. It calculates the distance from the sensor to the surface of the liquid to be measured from the time between the emission and reception of sound waves. It adopts non-contact measurement, and the measured medium is almost unlimited. It can be widely used in Height measurement of various liquid and solid materials in atmospheric storage tanks, process tanks, small tanks and small vessels, pump lift stations, waste water storage tanks, etc.

SenTec has been producing ultrasonic sensors for more than 20 years and developing technologies and products for ultrasonic applications. Ultrasonic series products include ultrasonic level meter (ultrasonic level meter, ultrasonic level meter), ultrasonic flowmeter, ultrasonic interface meter, ultrasonic water depth meter, tank body mounted liquid level meter, remote sonic well depth meter, ultrasonic (liquid, slurry) Body) concentration meter, ultrasonic tide gauge and other physical quantity sensors and instrument systems. SenTec Is a professional manufacturer of industrial inspection ultrasonic technology.