The vortex flowmeter is a volume flow meter that measures the volume flow of gas, steam, or liquid, the volume flow of standard conditions, or the mass flow of gas, steam, or liquid-based on the Karman vortex principle. When the fluid flows through the dust collector rod of the vortex flowmeter, a vortex is formed. The frequency of vortex shedding is proportional to the fluid velocity. Temperature and pressure compensation can be configured.

Vortex flow meter working principle

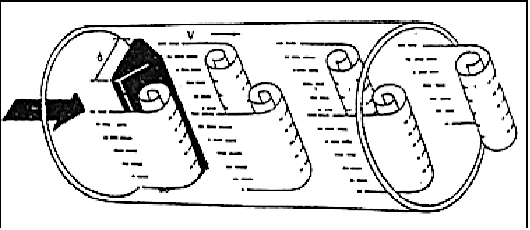

If a non-streamline vortex generator (bluff body) is set in the fluid, two rows of regular vortices are alternately generated from both sides of the vortex generator. This type of vortex is called a Karman vortex, as shown in Figure.

At the downstream of the vortex generator, alternate and regular vortex rows are formed. Suppose the frequency of the vortex is f, the average velocity of the incoming flow of the measured medium is V, and the width of the front face of the vortex generator is d. According to the Karman vortex street principle, the following relational formula:

Formula (1) where:

f-Carman vortex frequency HZ generated on one side of the generator

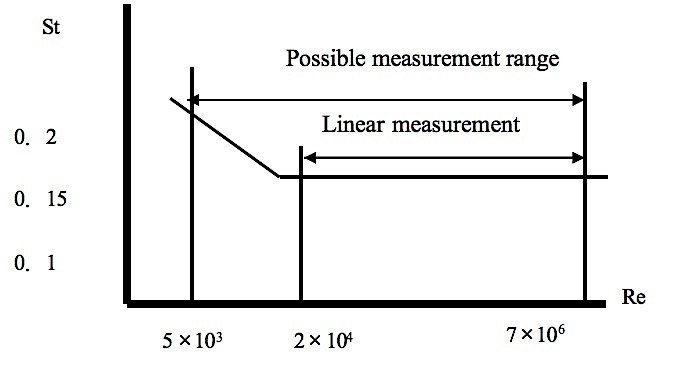

St-Strouhal number (dimensionless number)

V-The average flow velocity of fluid (m/s)

d-Width of vortex generator (m)

In the straight part of the curve table with St=0.17, the release frequency of the vortex is proportional to the flow velocity, which is the measurement range of the vortex flow sensor. As long as the frequency f is detected, the flow velocity of the fluid in the tube can be obtained, and the volume flow rate can be obtained from the flow velocity V. The ratio of the measured pulse number to the volume is called the meter constant (K), see formula (2)

K=3600f/Q(1/m³)

Formula (2) where:K = meter constant (m-3).

f = number of pulses

Q=Volume flow rate (m³)

Where a vortex flow meters apply for?

Vortex flowmeter is mainly used for industrial pipeline medium fluid flow measurement. Such as gas, liquid, vapor and other media. Here are some related applications.

types of vertex flowmeter

SenTec mainly manufacturer 2 typs of vertex flowmeter, which are Pipe type vortex flowmeter and Insertion type vortex flowmeter.

Pipe type vortex flowmeter. Generally used for small and medium diameter pipe flow measurement;

Insertion type vortex flowmeter. Mostly used for large-diameter pipeline flow measurement.

According to different measuring medium or application, Sentec vertex flowmeter also desinged with EX type, high-temperature typ, corrosion-resistant type etc.

Explosion-proof vortex flowmeter. Used in petroleum, chemical industry for the instrument explosion-proof requirements of the occasion;

High-temperature vortex flowmeter. For the measurement of high-temperature media;

Ultra-low temperature type vortex flowmeter. Used for liquid nitrogen, liquid oxygen, and other ultra-low temperature medium measurement;

Corrosion-resistant vortex flowmeter. Used for acid, alkali, salt, and other corrosive media measurement;

Mass type vortex flowmeter. Used for the measurement of fluid quality

Applications of Vortex Shedding Flow Meter

Vortex flowmeter is a volume flowmeter that measures the volume flow of gas, steam or liquid, the volume flow of standard conditions or mass flow according to the Karman vortex principle. Mainly used for flow measurement of industrial pipeline medium fluid, such as gas, liquid, steam and other media.

1.Steam Flow Measurement

Vortex meters are known to be superior devices for steam flow measurement, due to their inherent linear measurement, large turndown, low-pressure drop, and high accuracy.

The vortex flowmeter is ideal for high temperature, superheated, and saturated steam applications, since it eliminates the need for separate components and associated installation temperature.

In addition, it provides quality, dependability and high-pressure ratings,along with a stable and reliable flow measurement.

2.Liquid Flow Measurement

Liquid applications in the oil refinery industry become challenging, since the process liquid is a higher viscosity at lower process temperatures.

As a result, clogging becomes an issue when a flow meter has moving parts.

SenTec vortex meters have advanced self-diagnostics, that alert the operator if clogging or plugging in the area around the shedder bar are present.

Alerts are also triggered in high-vibration environments and those with excessive flow fluctuations in the area around the shedder bar. This enables automatic condition-based maintenance.

Vertex Flowmeter installation attentions:

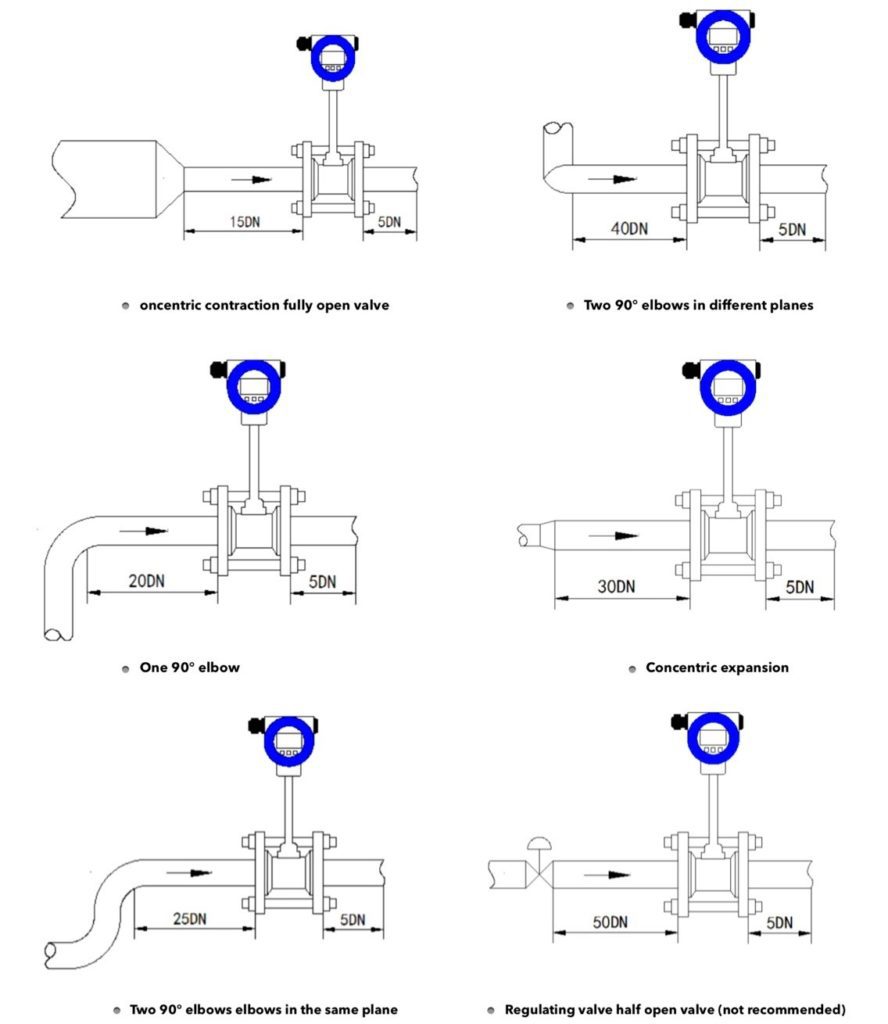

Vertex flowmeter shall be installed in horizontal, vertical, inclined (liquid flow from bottom to top) pipes with the same diameter. The upstream and downstream of the sensor shall be equipped with a certain length of straight pipe section, whose length shall meet the requirements of front straight pipe section 15-20D and rear straight pipe section 5-10D.

The pipeline near the installation of liquid sensor shall be filled with the measured liquid.

The sensor shall not be installed on the pipeline with strong mechanical vibration.

The inner diameter of the straight pipe section shall be consistent with the sensor diameter as much as possible. If it cannot be consistent, the pipe with a slightly larger diameter than the sensor diameter shall be used, and the error shall be ≤ 3% and no more than 5mm.

Note:The sensor shall not be installed in the place with strong electromagnetic field interference, small space and inconvenient maintenance.

how to select the vortex flowmeter ?

The correct selection of the vortex flowmeter is a prerequisite for ensuring the good use of the vortex flowmeter. Important factors to be considered: passage (DN), installation method, medium temperature, output signal, and medium type.

Vortex Flow Meter selection points

The correct selection of the vortex flowmeter can ensure the better use of the vortex flowmeter. What type of vortex flowmeter should be selected according to the physical and chemical properties of the fluid medium to be measured? Make the diameter, flow range, lining material, electrode material and output current of the vortex flowmeter suitable for the fluid to be measured. properties and flow measurement requirements.

1. Precise functional inspection

Accuracy class and function Select the instrument accuracy class according to the measurement requirements and application occasions.

2. Measurable medium

When measuring medium flow rate, instrument range and caliber to measure general medium, the full-scale flow rate of the vortex flowmeter can be selected within the range of 0.5-12m/s of the measured medium flow rate, and the range is relatively wide. The specification (diameter) of the selected instrument is not necessarily the same as that of the process pipeline. It should be determined according to whether the measurement flow range is within the range of the flow rate, that is, when the flow rate of the pipeline is too low to meet the requirements of the flow meter or the measurement accuracy cannot be guaranteed at this flow rate, It is necessary to reduce the diameter of the instrument to increase the flow rate in the pipe and obtain satisfactory measurement results.

3. Selection of vortex flow transmitter

Piezoelectric vortex flow transmitter is used in saturated steam measurement. Due to the wide range of vortex flowmeter, in practical applications, it is generally considered that the flow rate of saturated steam shall not be lower than the lower limit of the vortex flowmeter. That is to say, the fluid velocity must not be lower than 5m/s. Vortex flow transmitters with different diameters are selected according to the size of the steam consumption, and the diameter of the transmitter cannot be selected with the existing process pipe diameter.

4. Selection of pressure compensation pressure transmitter

Because the saturated steam pipeline is long and the pressure fluctuates greatly, pressure compensation must be used. Considering the corresponding relationship between pressure, temperature and density, only pressure compensation can be used in the measurement. Since the saturated steam pressure of the pipeline is in the range of 0.3-0.7MPa, the pressure The range of the transmitter can be selected as 1MPa.

5. Display instrument selection

Display instrument Intelligent flow display instrument, with voltage stabilization compensation, instantaneous flow display and cumulative flow accumulation functions.