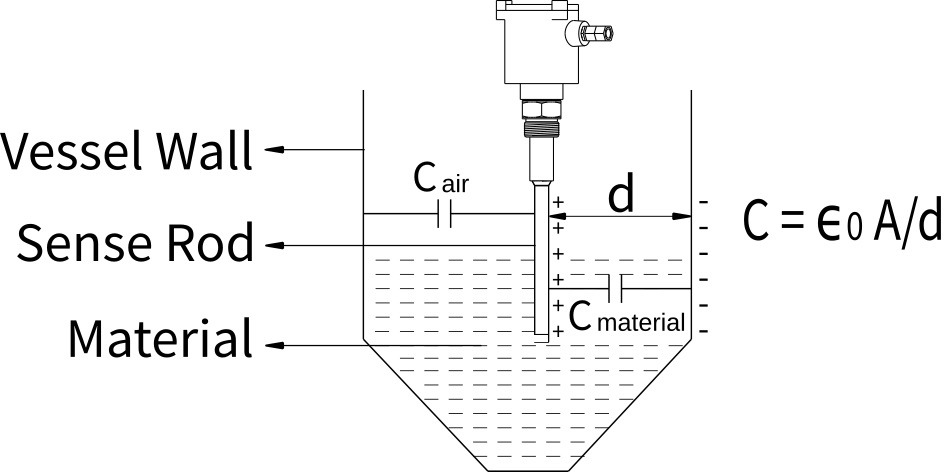

Capacitive Level switch Sensors can be used for point level detection and continuous level measurement, particularly in liquids. The measuring principle is based on the change of the capacitance in a capacitor. The electrically conductive tank wall and a probe inside of the tank form a capacitor, The capacity changes of which are used to determine the level. This animation shows the measuring principle in conductive liquids and non-conductive liquids.

Capacitive level switch working principle

The capacitive liquid level switch determines whether there is a medium or air by detecting the conductivity or insulation rate of the medium. Capacitance is formed between the level switch and the medium (liquid or air) it is in. When the probe tip of a capacitive level switch is immersed in liquid, the capacitance changes dramatically and the FET switch changes state. Capacitive level switches can operate in relatively clean, conductive, junction-free liquids. Including process water, hydrogen peroxide and other industrial fluids.

Measuring Principle of Capacitor Level Switch: The relay in the capacitor works and outputs a switch value to achieve the purpose of control (or alarm).

What are the advantages of capacitive liquid level switch?

Capacitive liquid level switch advantages can measure various liquids with conductivity and no junction layer; IP68 probe and cable can operate under liquid surface; Capacitive liquid level switch relay output can be connected with PLC or alarm; PP/PFA material is used to resist acid Alkali corrosion; with super anti-hanging function.

where the capacitive level switch apply for?

Capacitors have been successfully used in the following applications:

◆ Flour factory: Detect the level of flour and wheat grains

◆ Feed factory: Detect soybean meal level

◆ Power plant: check the level of fly ash

◆ Glass factory: check the level of quartz sand and broken glass

◆ Construction machinery: check the cement silo material level

◆ Foundry machinery: detection of sand level

◆ Hydraulic machinery: detect lubricating oil level

◆ Chemical factory: detect the liquid level of polyester, spandex, acid, alkali and other chemical materials

◆Environmental protection: detect sewage level

◆ Boiler plant: Detecting the water level of the steam drum and other pressure vessels

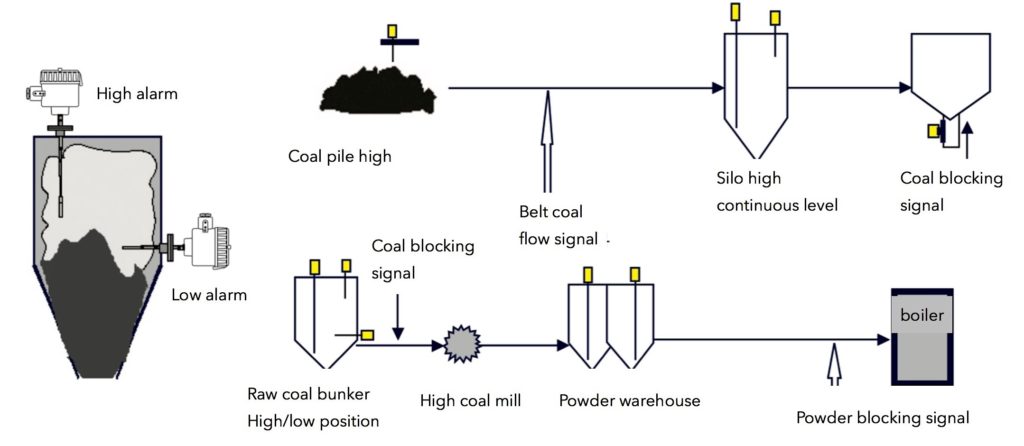

Applications of Capacitance Level Probes level switch in silo coal powder tank

It has high resolution, good consistency, wide measurement range, and solves the problem of material adhesion. It can measure various mineral powders, sand, cement, flour, various oils, various liquids, strong acids, strong alkalis, etc. It is widely used in construction, metallurgy, petroleum, chemical, food, pharmaceutical, papermaking, electric power, sewage treatment and other industries.

This picture covers ore silo, iron crystal silo, batching silo, white ash silo, coke silo, dust collection silo, raw coal silo, sinter silo, hot silo, dust collection silo, raw coal silo, sinter silo, hot material

silo, cold silo, etc.

Note:

1. Horizontal rod switches cannot be used for block materials, only flat switches (high and low) and cable switches (high) can be used

2. The continuous meter can only be used for the measurement of powder insulating materials.

How to install a capacitive level switch?

Capacitive liquid level switch installation steps:

1. The level switch is usually installed on the side wall of the silo body by side installation (installed on the side of the silo wall), and the upper and lower limit positions of the material level height are detected. top mounting) method.

2. When installing on the side, the threaded installation pipe should be as short as possible, so that the end of the probe thread and the inner wall of the groove are flush to avoid material accumulation at the root.

3. When top-mounted, the distance between the electrode and the warehouse wall should be greater than 200mm, and a position that can avoid the impact of the material during feeding should be selected.

4. When the warehouse wall is concrete, the level switch shell should be reliably connected to the steel bar, and when the warehouse wall is non-metallic, an auxiliary probe should be installed

5. When measuring solid powder or block material with a large specific gravity, the probe should be fixed to prevent the material side pushing the probe from deviating from the normal position. When measuring liquids, if there is a stirring device, the cable probe should also be fixed.

6. When users disassemble and assemble the level switch, it is forbidden to hold the shell by hand and twist it, and use a wrench to twist the hexagonal bolt.

How to order a capacitive level switch?

Selection considerations

1. The probe length of the level switch is selected between 100-2000mm, which is a rod probe. Cable probes can be used for probes with a length of more than 2000mm.

2. When used to detect materials with dielectric constant < 3 such as plastics, the length of the probe should not be shorter than 500mm. Auxiliary probes are required for non-metal silos or materials with a dielectric constant less than or equal to 1.8.

3. When there are high-power equipment on site, the 24VDC power supply should be used as much as possible.

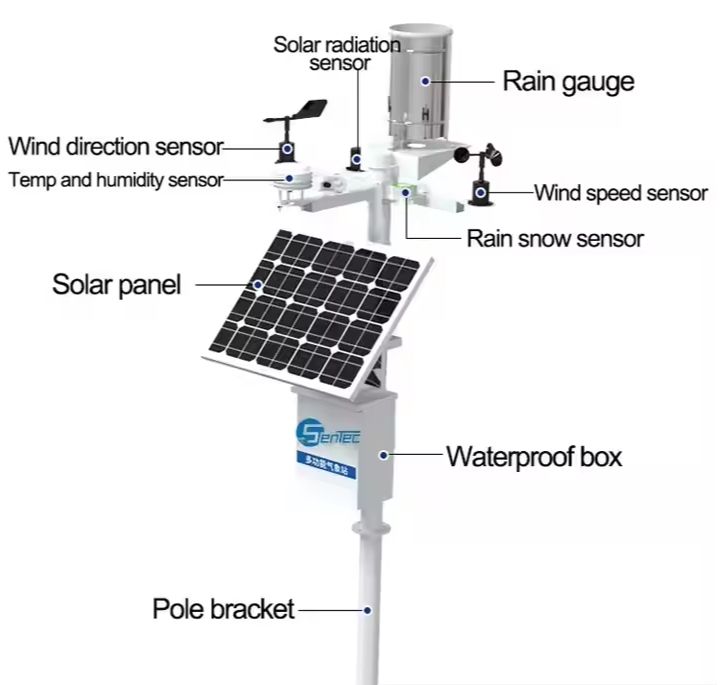

※Note: As one of the earlier Capacitive Level measurement manufacturer, SenTec provide A wide variety of Capacitive Level switch Sensors for tank level measurement solutions.