Capacitive level sensor also called Capacitive liquid level gauge is a device that converts the change of the position of the measured object into capacitance. The capacitive liquid level gauge has simple structure, high resolution, reliable operation, fast dynamic response, non-contact measurement, and can be measured at high temperature. The advantages of working under harsh conditions such as radiation and strong vibration have been applied in various fields of industrial and agricultural production. However, traditional capacitive level gauges all use analog circuits. Due to the change of the dielectric constant of the measured medium, stray capacitive interference, temperature drift, scraping and other factors, the traditional capacitive level gauge has The scope of application is limited.

How does a capacitive level sensor work?

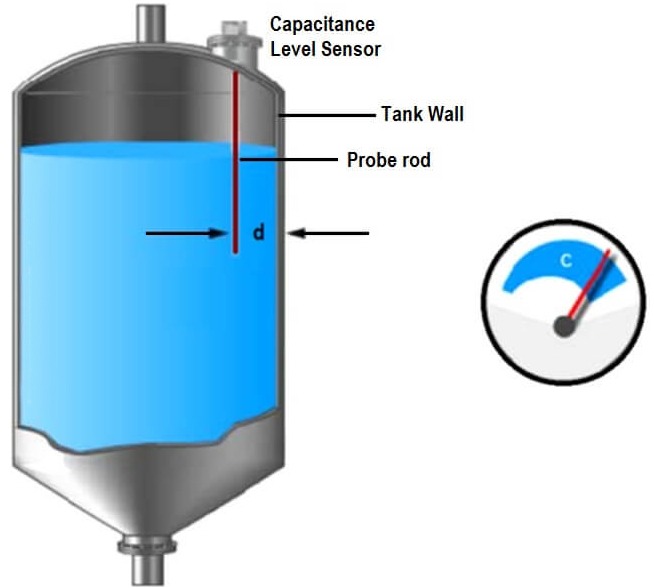

The principle of capacitive level measurement,is based on the capacitance change of a capacitor.

The probe and the tank wall form a capacitor, whose capacitance is dependent on the amount of product in the tank:

An empty tank has a lower, a filled tank a higher capacitance.

A simple capacitor consists of two electrode plate, separated by a small thickness of an insulator, such as solid, liquid, gas, or vacuum.

This insulator is also called as dielectric. Value of C depends on dielectric used, area of the plate and also distance between the plates. capacitance equation.

What are the Capacitance Level sensor used for?

Capacitance Level Probes are used for measuring level of:

*Liquids level measurement

*Powered and granular solids level measurement

*Liquid metals at very high temperature level measurement

*Liquefied gases at very low temperature level measurement

*Corrosive materials like hydrofluoric acid level measurement

*Very high-pressure industrial processes level measurement

How Capacitive liquid level sensors used for car fuel level monitor ?

Capacitive liquid level sensors are installed in the fuel tank perpendicular to the fuel level relative to the normal driving state of the car. The two inner and outer tubes are equivalent to the polar plates of the capacitor and need to maintain a certain gap, which can be measured by the position change of the fuel level. remaining oil.

The capacitive liquid level sensor has the advantages of large dynamic range, fast response speed, small zero drift, simple structure and strong adaptability.

Capacitive level sensor VS Hydrostatic level sensor

1. Capacitive liquid level transmitter is the core sensor working principle of a transmitter. Refers to an instrument that measures differential pressure by detecting changes in capacitance on both sides of the sensing diaphragm. Theoretically, it can measure the pressure and differential pressure in any form, including liquid level. The reason why it is called a liquid level transmitter is only because its installation method is specially designed for liquid level measurement. The essence of the capacitive liquid level transmitter is a differential pressure transmitter.

2. Hydrostatic level sensor refers to a method of measuring liquid level using the principle of Hydrostatic pressure. Liquid level height × medium weight = pressure difference between liquid level and upside. This method of measurement requires the use of a differential pressure transmitter. If this differential pressure transmitter is designed to be more suitable for liquid level measurement, it is called a liquid level transmitter.

Capacitance Level Probes sensor Applications

The capacitive liquid level gauge adopts a fully digital capacitive measurement method and uses multi-parameter compensation technology to develop a series of high-precision liquid level gauges, which have been successfully used in many fields. Such as capacitive oil level sensors installed in motor vehicles, capacitive high temperature and high pressure liquid level gauges used in various high-risk occasions such as strong corrosion, high temperature, high toxicity and explosion, and can automatically adapt to high-precision universal fluids of various media. These level gauges have been tested in relevant industries and have been well received.

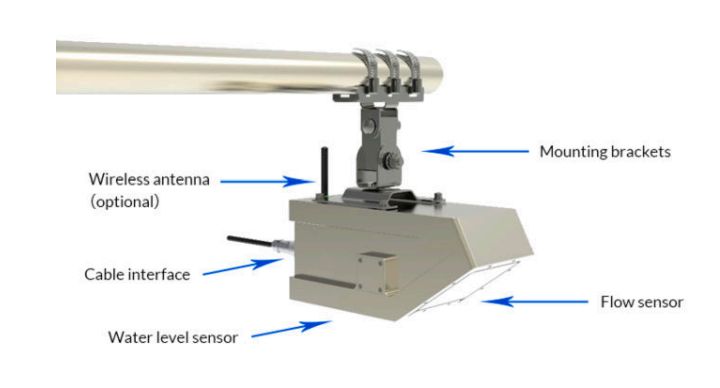

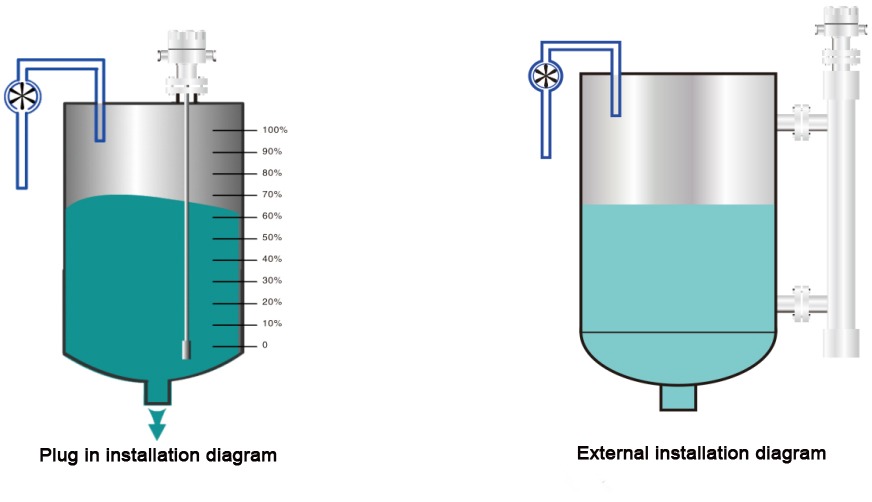

The universal liquid level meter has a variety of installation and fixation methods to adapt to different site conditions. When the process facilities such as internal thread or flange cannot be provided on site, three installation methods can be selected, i.e. wall installation, horizontal pipe rack and vertical pipe rack, so that you can easily install them on site.

※Note: As one of the earliest Capacitive level sensor manufacturer, SenTec provide a wide variety level measurement solutions, such as Hydrostatic level sensor, Ultrasonic level sensor, Radar Level Transmitters, Magnetostrictive Level Transmitter, Capacitive Level Sensor, Level Switch Sensor etc.

For specific Capacitive level sensor price, please contact our sales engineer.