A gas sensor is a converter that converts a certain gas volume fraction into a corresponding electrical signal.

What the gas sensor used to measure?

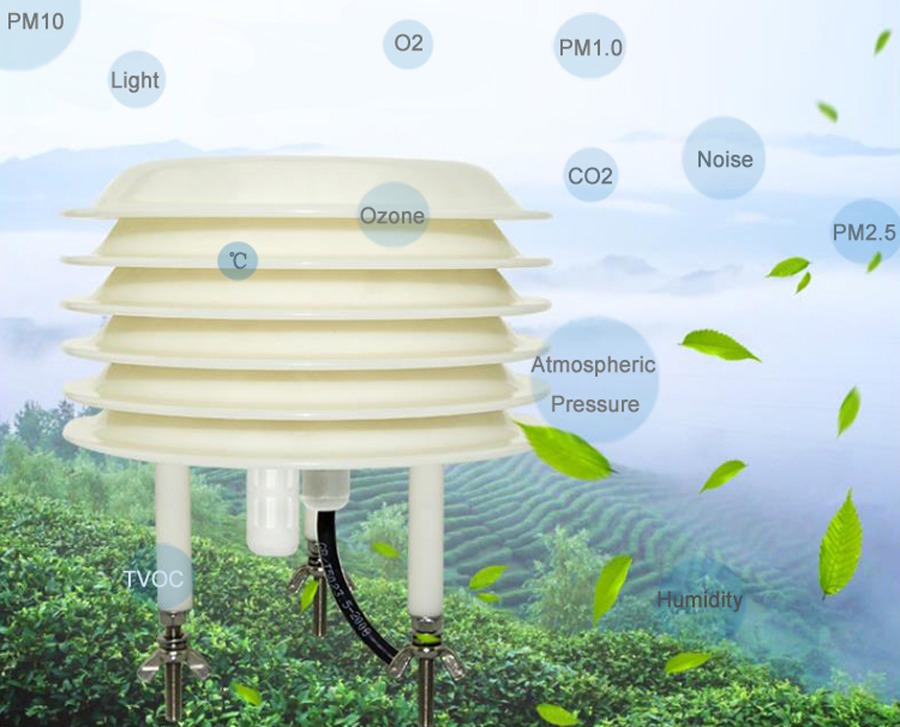

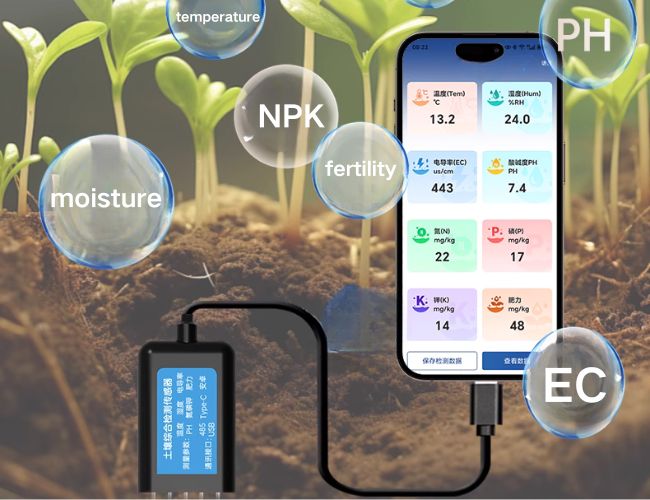

Gas sensor can measure CO carbon monoxide transmitter, CO2 carbon dioxide transmitter, industrial wall-mounted carbon dioxide transmitter, O2 oxygen transmitter, O3 ozone transmitter, sulfur hexafluoride transmitter, hydrogen sulfide transmitter, Ammonia transmitter, sulfur dioxide transmitter, nitrogen dioxide transmitter, TVOC transmitter, phosphine transmitter, hydrogen transmitter, methane transmitter, formaldehyde transmitter, etc.

Gas sensor working principle

“Gas sensors” include semiconductor gas sensors, electrochemical gas sensors, catalytic combustion gas sensors, thermal conductivity gas sensors, infrared gas sensors, solid electrolyte gas sensors, and the like.

Determine the type of sensor according to the measurement object and measurement environment. To carry out a specific measurement work, we must first consider which principle sensor is used, which can only be determined after analyzing various factors. Because, even for the measurement of the same physical quantity, there are sensors with a variety of principles to choose from. Which sensor is more suitable, you need to consider the following specific issues according to the characteristics of the measured and the conditions of use of the sensor: the size of the range; The requirements of the measured position on the sensor volume; whether the measurement method is contact or non-contact; the signal extraction method, wired or non-contact measurement; the source of the sensor, whether it is domestic or imported, and whether the price can be afforded, or self-developed. After considering the above problems, it is possible to determine which type of sensor to choose, and then consider the specific performance indicators of the sensor.

What is the NDIR Infrared Gas Analyzer ?

NDIR infrared gas sensor is a kind of gas sensor based on the selective absorption characteristics of the near-infrared spectrum of different gas molecules, using the relationship between gas concentration and absorption intensity (Lambert-Beer law) to identify gas components and determine their concentration device.

types of gas sensor

*Semiconductor gas sensor

This type of sensor accounts for about 60% of gas sensors. According to its mechanism, it is divided into conductive type and non-conductive type, and the conductive type is divided into surface type and volume control type.

*Solid electrolyte gas sensor

This sensor element conducts ions to the solid electrolyte membrane, called an electrochemical cell, and is divided into cation conduction and anion conduction

*Contact combustion gas sensor

Contact combustion sensor is suitable for detection of combustible gas H2, CO, CH4

* Electrochemical gas sensor

There are two commonly used electrochemical gas sensors:

(1) Potentiostatic electrolytic sensor

(2) Primary battery gas sensor

* Optical gas sensor

(1) Direct absorption gas sensor

(2) Light reactive gas sensor

(3) New sensors for optical properties of gases

In addition, sensors that use other physical quantity changes to measure gas components are constantly being developed. For example, surface acoustic wave sensors have high sensitivity in detecting SO2, NO2, H2S, NH3, H2 and other gases.

Semiconductor Gas Sensors VS Electrochemical Gas Sensors VS Infrared Gas Sensors

In the future, gas detection instruments and meters using semiconductor and catalytic principles will still occupy part of the low-end market by virtue of their price advantages. Electrochemical gas sensors and detection instruments have outstanding comprehensive advantages in the fields of low-concentration toxic gas, organic vapor, alcohol gas, and oxygen monitoring with high precision requirements. Infrared gas sensors and instruments are suitable for monitoring all kinds of flammable, explosive, and carbon dioxide gases. They have significant advantages such as high accuracy, good selectivity, high reliability, no poisoning, no dependence on oxygen, less environmental interference, and long life. . These advantages will lead to gas detection instruments based on electrochemical and infrared principles occupying a wider high-end market in the industry, and will gradually become the mainstream of the market in the future

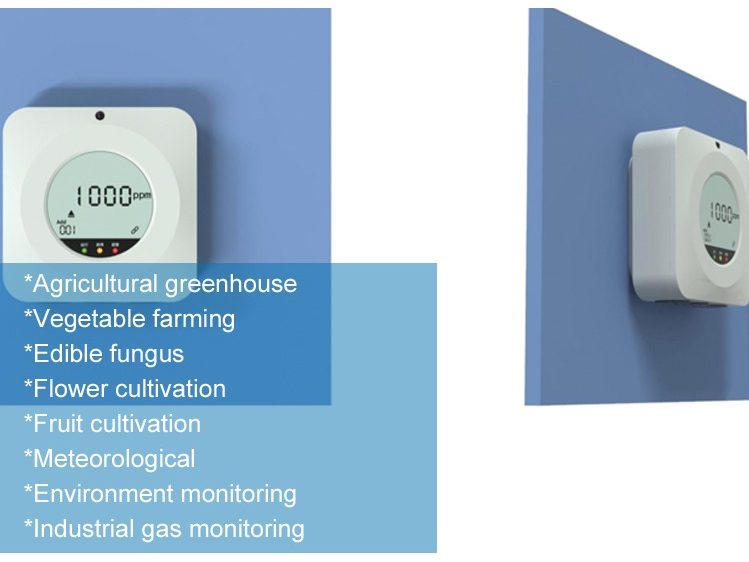

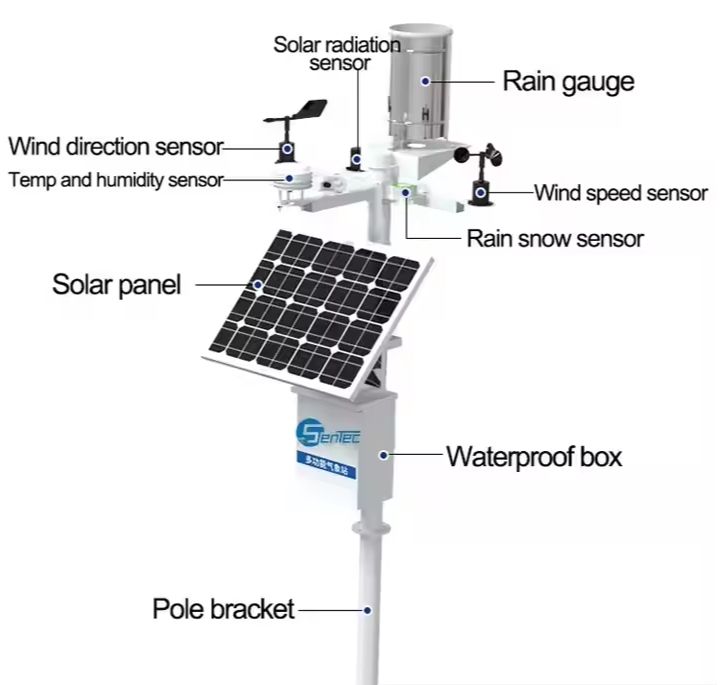

Gas sensor application

Infrared sensors are widely used and are used in the detection of many kinds of gases. Most of Sentec products use infrared verification technology for gas concentration measurement, such as CO2 infrared sensors. A gas sensor is a gas sensing device that selects absorption characteristics based on the near-infrared spectrum of different gas molecules, and uses the relationship between gas concentration and absorption intensity to identify gas components and determine their concentration.

Compared with other types of gas sensors, such as electrochemical type, catalytic combustion type, semiconductor type, etc., gas sensor has a wide range of applications, long service life, high sensitivity, good stability, suitable for many gases, high cost performance, low maintenance cost, online analysis, etc. And a series of advantages. It is widely used in petrochemical, metallurgical industry, industrial and mining, air pollution detection, agriculture, medical and health and other fields.