High pressure transducer is a pressure transmitter suitable for high pressure measurement and control.

SenTec high pressure transducer has gone through thousands of fatigue impact tests and several days of low and medium temperature aging cycles before leaving the factory. It has solved the disadvantages of high pressure sensors in terms of stress and zero instability. Provide customers with reliable products for high voltage measurement. The pressure of PM460 series high pressure sensor can reach 600MPa.

How a high pressure sensor works ?

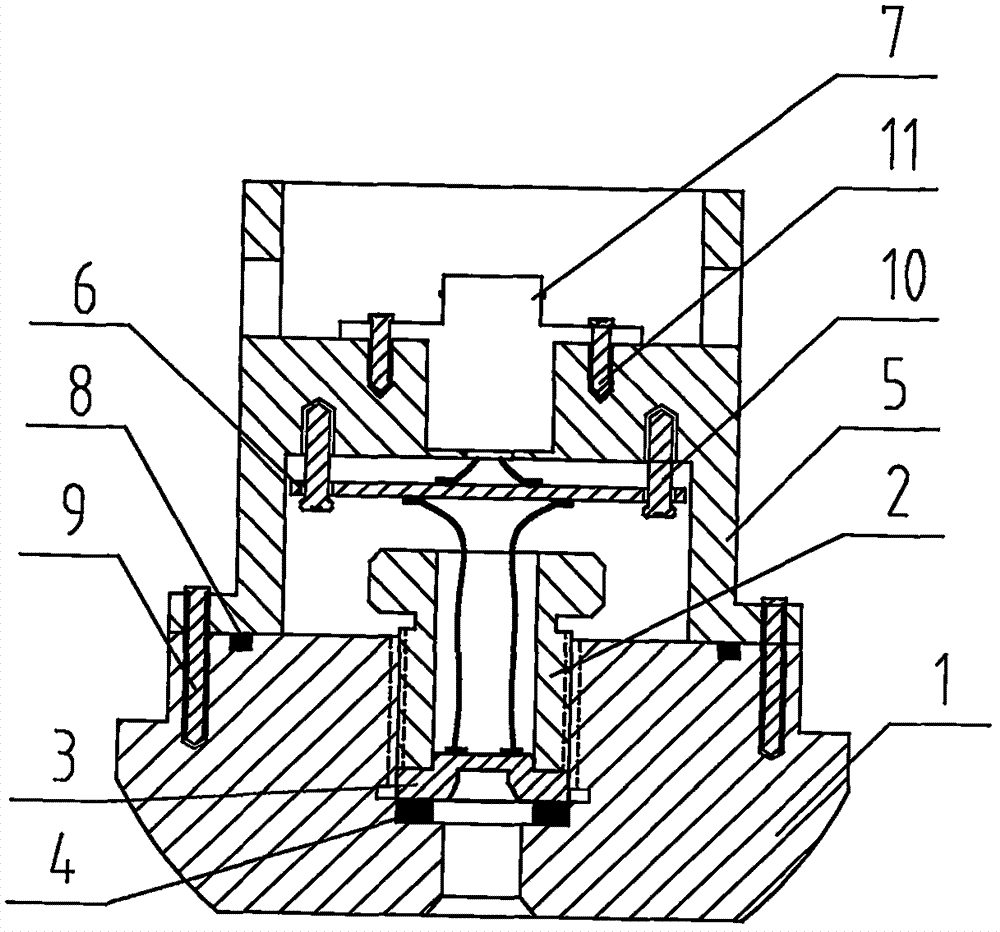

The union pressure sensor is also called a high pressure sensor. The sputtering film pressure sensor is a pressure sensor with excellent performance formed by depositing insulating materials, strain sensitive materials, protective materials, etc. on the surface of the elastomer by vacuum atomic thin film deposition technology. It has the advantages of high precision, good stability, wide operating temperature range, high reliability and long working life. Using the sputtering film pressure sensor core and reasonable union structure design, a new type of union pressure sensor is manufactured, which can be applied in the fields of oil and gas drilling, cement grouting and cementing, and can solve the above problems well.

What is the hammer union pressure transmitter manufacturer process?

The method for manufacturing a union pressure sensor includes the following steps:

s1. Use a machining method to manufacture an inverted U-shaped cup-shaped sensitive core, grind and polish the upper surface of the sensitive core, and use thin film deposition technology and pattern transfer technology to manufacture pressure-sensitive cores on the upper surface of the sensitive core. Acting strain resistance and forming a measurement circuit, and then performing high temperature annealing treatment on the sensitive core;

s2. Use a machining method to manufacture a pressure-inducing hole at the lower center, a ball head upper cavity communicating with the upper center position and the pressure-inducing hole, an inner thread on the edge of the ball head upper cavity, and a sealing groove at the upper periphery , the ball head of a plurality of evenly distributed ball head screw holes located outside the sealing groove;

s3. Use machining methods to manufacture fastening bolts with a central through hole in the center and an external thread at the lower end;

s4. Use a machining method to manufacture a housing lower cavity located at the lower part, a housing upper cavity located at the upper part and communicated with the housing lower cavity, and a plurality of uniformly horizontally distributed upper housings communicated with the housing upper cavity. A casing with a cavity through hole and a plurality of casing screw holes evenly distributed on the outer periphery of the lower part;

s5. Use welding equipment to weld inner leads on the core pads on the upper surface of the sensitive core;

s6. Place the purchased O-type gasket on the bottom support boss of the upper cavity of the ball head, place the sensitive core body welded with the inner lead on the O-type gasket, and place the The fastening bolt is screwed into the upper cavity of the ball head along the inner thread of the ball head, so that the lower end face of the fastening bolt is pressed against the upper step of the core body of the sensitive core body, and the inner lead is passed through the ball head. the central through hole of the fastening bolt;

s7. Connect the inner lead to the corresponding input terminal on the conditioning circuit board;

s8. The conditioning circuit board is mounted on the top of the lower cavity of the casing by means of fixing screws;

s9. Connect the signal output end of the conditioning circuit board to the input end of the connector through the outer lead;

s10. Install the connector at the bottom center position of the upper cavity of the housing, and fix it by plugging screws;

s11. Install the O-ring seal on the sealing groove of the ball head;

s12. Use sealing screws to pass through the housing screw holes to fix the housing on which the conditioning circuit board and the connector are installed on the ball screw holes of the ball head, and make the housing and the ball head connect to each other. In this way, a new type of union pressure sensor product is obtained;

s13. Perform high and low temperature and alternating fatigue tests on the new type of union pressure sensor product;

s14. Marking and calibrating the new type of union pressure sensor product, and packaging it into storage.

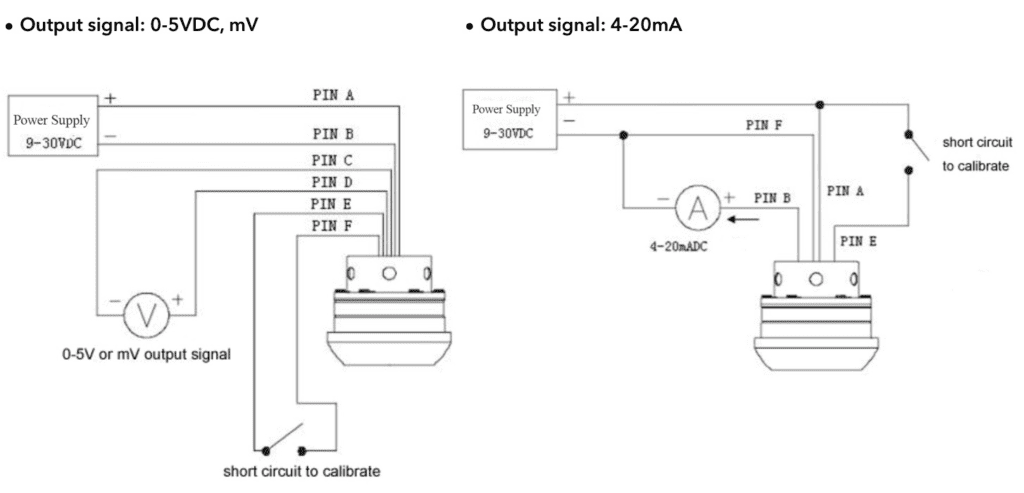

How to wire high pressure transducer ?

Fracturing truck pressure transmitter can replace various imported fracturing truck sensors such as American Vtron, GE, Honeywell, Stevenson, Stewart, Bijie and so on.