The laser water level meter uses laser to measure the water level. It is a non-contact device. It is mainly used to measure the water level of rivers, lakes, reservoirs, channels, water pipe networks, etc., and provide real-time water level data for relevant units. SRL900 laser water level gauge is simple in structure, durable and reliable, RS-485 standard communication interface, can be connected with a variety of equipment; the shell is all stainless steel package, the operating temperature range is -40 ° C ~ 70 ° C, the operating humidity range is 0 ~ 95%, can Meet the requirements of complex working environment.

NON-CONTACT LIDAR RADAR LEVEL SENSOR WORKING PRINCIPLE

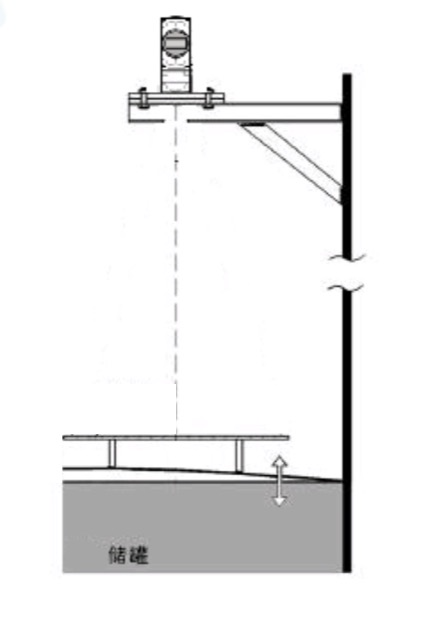

The laser level gauge has built-in visible laser aiming at the measured medium, and a built-in high-precision high-resolution timing device measures the round-trip time of the infrared laser between the launch point and the measured medium, then L = t * c / 2 (t is the round trip time, c For the speed of light). The laser level gauge is a non-contact measurement. Because the laser can penetrate the glass, the laser level gauge can be well protected and can be used for harsh environment measurement (high temperature, high pressure, high humidity, high dust). Since the laser emission angle is very low (<0.2°), the laser level gauge measures the small space level and allows accurate measurement of irregular surfaces.

A continuous or high-speed pulse laser beam is emitted by a semiconductor laser. The laser beam is reflected on the surface of the measured object, and the light returned is received by the laser receiver. The time difference between laser transmitting and receiving is recorded accurately to determine the distance from lidar to the measured object.

The distance d from the material surface is proportional to the time travel t of the pulse:

D = C × T / 2, where C is the speed of light

Since the distance E of the empty tank is known, the level L is: L=E-D

According to the range and full degree information set by the user, the processor calculates the percentage of the current material level, and then outputs analog signals such as 4-20mA or 0-5V, digital signals of RS485 modbus, switch signals of warning and alarm relays, etc. in proportion.

NON-CONTACT LIDAR RADAR LEVEL GAUGE APPLICATION

Lidar radar level transmitter sensor application:

*Pharmaceutical production

*Plastic production, high-risk areas for plastics

*Warehousing industry such as crude oil, refined oil measurement

*Cement and aggregates – raw materials, clinker silos, etc.

*Food processing, cereals, seeds and feed, aggregate industry

*Environment and recycling industry, polymerization reactor vessel (high pressure)

*Chemical processing, bio-energy, liquid asphalt, reactor vessel (vacuum), alloy polystyrene, nylon, polyvinyl chloride, etc.

*Pulp and paper, such as pulp pulp pool, sealed pool, white pool, storage tank, storage tower, bleaching tower.

*Mining, metallurgy, colored smelting