The target flow meter is also known as the drag force flow meter. Insert a target (drag element) into the flow field. Measure the drag force on the inserted target and convert it to the flow velocity

How Target Flowmeters Work ?

Target flowmeters measure flow by measuring the amount of force exerted by the flowing fluid on a target suspended in the flow stream.

The force exerted on the target by the flow is proportional to the pressure drop across the target. Like differential pressure flowmeters. Bernoulli’s equation states that the pressure drop across the target (and hence the force exerted on the target) is proportional to the square of the flow rate.

Using this relationship, 10 percent of full scale flow produces only 1 percent of the full scale force.

At 10 percent of full scale flow, the target flowmeter accuracy is dependent upon the transmitter being accurate over a 100:1 range of force.

Transmitter accuracy is typically degraded measuring low forces in its range, so flowmeter accuracy can be similarly degraded.

So, this non-linear relationship can have a detrimental effect on the accuracy and turndown of target flowmeters.

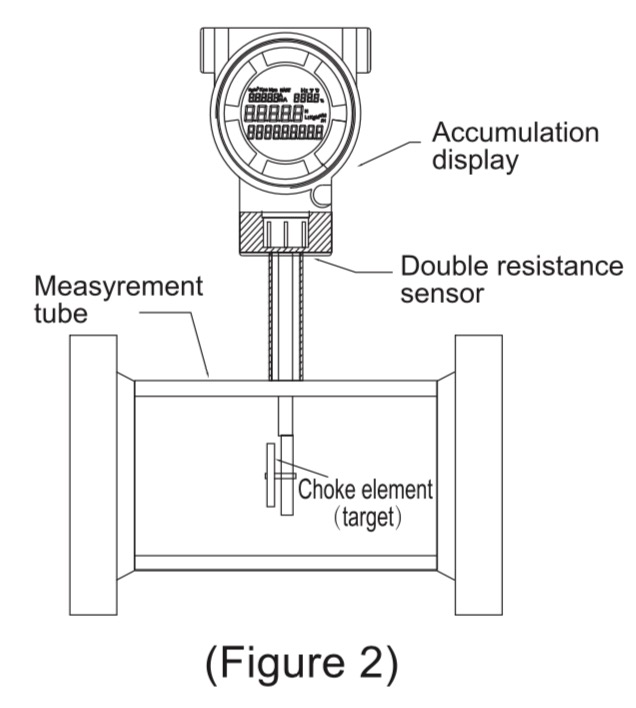

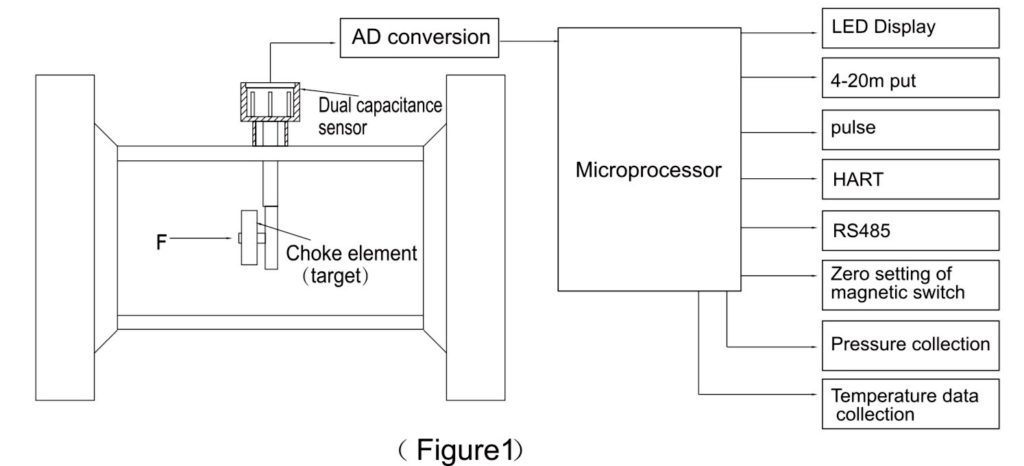

Target flowmeter working principle

When the medium flows in the measuring tube, the pressure difference is generated by its own kinetic energy during flowing the blocker (target) and has acting force to choke element which the magnitude of its action force is direct ratio to the square of the medium flow velocity. The acting force F received by the choke element (target) is transmitted to the dual capacitance sensor through the rigid connecting transmitter (measuring bar). The capacitor light generated by the dual capacitance sensor is processed by the high precision AD chip, and the digital signal is output directly. Thus, after AD conversion and computer processing, the corresponding instantaneous flow and cumulative total amount can be obtained.

The working principle is shown in figure

What Target Flowmeters used to measure ?

Target flowmeters inferentially measure the flow of liquids and gases. Such as water, air, industrial gases, and chemicals. Be careful using target flowmeters on fluids that can coat the target. Because the flowmeter accuracy can be degraded.

This flowmeter can be applied to sanitary, cryogenic liquids, relatively clean, and corrosive liquids. The materials of construction of all wetted parts, including the flowmeter body and seals, should be considered.

Inline target flowmeters are available up to approximately 6 inches in size. Insertion target flowmeters are available for larger line sizes.

Sanitary type target flowmeter Applications requiring sanitary piping systems are often found in the pharmaceutical and chemical industries. Such as in the manufacture of drugs and vitamins. Sanitary applications are especially prevalent in the food and beverages industry where cleanliness is important.

What are the Advantages of Target flow meters ?

*They are useful for difficult measurements. Such as slurries, asphalt(so it also called bitumen flowmeter), polymer bearing and sediment-bearing materials corrosive mixtures, etc.

*They are good for relatively high temperatures and pressures.

*Can be used with a wide variety of fluids, even viscous fluids and slurries.

*Can be used in abrasive, contaminated, or corrosive fluid flow

*Can be made to measure flow velocity that is sporadic or multi-directional with sphere drag element designs

*Can be used for any type of liquid, gas, or steam cryogenics.

*There is no moving parts such as bearings, to wear out causing failures.

*High reliability where life tests have been made to 20,000,000 cycles.

*Can be used for any line size from 0.5 inches and up with any type of mounting.

*Range/fluid changes accomplished by simply changing targets.

*Turndowns aprox.15:1

*Several materials are available. Among them 303/304 SS, 316 SS, hastelloy and inconel.

TARGET FLOW METER APPLICATION

Typical applications of target flowmeters:

The target flowmeter not only has the characteristics of traditional target, orifice, vortex and other flowmeters without moving parts, but also has the measurement accuracy comparable to that of the positive displacement flowmeter, plus its unique anti-interference and anti-impurity performance. , Lightweight and reliable, widely used in petroleum, chemical, energy, food, environmental protection, water conservancy and other fields.

Gases: coal gas, air, hydrogen, natural gas, nitrogen, liquefied petroleum gas, hydrogen peroxide, flue gas, methane, butane, chlorine, mixed gas, etc.

Liquids: Heavy oil, paraffin, asphalt, sulfuric acid, edible oil, residual oil, acetone, diesel oil, mine water, detergent, soy sauce, gasoline, silicone oil, syrup, solvent, perfume, sea water, aviation kerosene, soap ketone water, glucose, vegetable oleic acid, Brine, paste, ink, coolant, glycol, mineral oil, liquid sugar, hydrochloric acid, car paint, resin, tallow, vegetable oil, liquid oxygen, shampoo, toothpaste, gel, fuel, milk, bleach , conditioners, soda, additives, cleaning agents, alkaline, ammonia, marine oil, chemical reagents, kerosene, glycerin, dyes, water, nitric acid, high boiling point organic solutions, lard, additives, alcohol, oil, ethylene, polypropylene , toluene, etc.

Steam: Superheated steam, saturated steam.

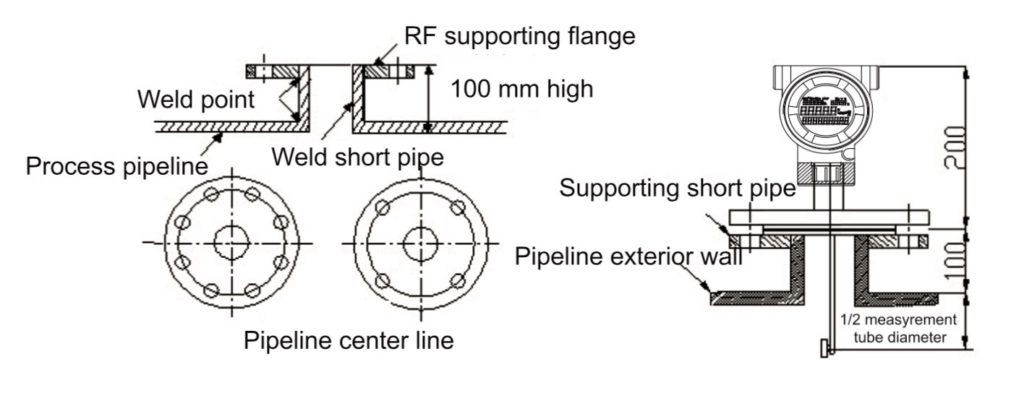

Target Flowmeters Installation:

A. Flowmeters of normal temperature type, low temperature type and high temperature type adopt horizontally, vertically or inverted installation according to different working conditions (the factory check list shall prevail);

B. When the working temperature of medium is above +300 C, users shall take insulation measures on the flowmeter shell to prevent heat radiation from damaging the meter header (the working temperature of the header is- 30 to + 70 C), and similarly , the medium with below -100 C working temperature shall also take anti-freeze measures;

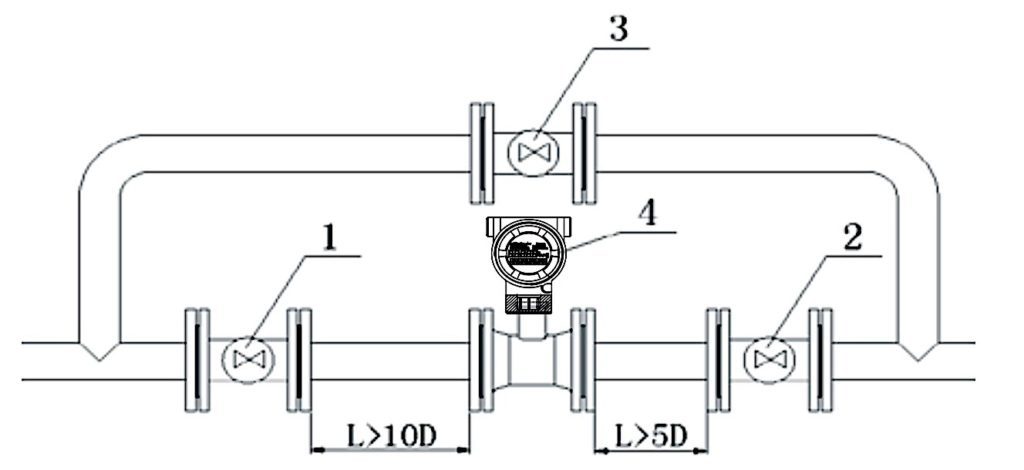

C. In order to ensure the accurate measurement of flowmeter, it is necessary to set up front and rear straight pipe section ;

D. In order to ensure that the flowmeter does not affect the system work during inspection and replacement, bypass valves (3) and stop valves (1, 2) should be set up as far as possible;

E. Vertical installation can be adopted due to process requirement. The flow direction of measured medium can be from bottom to top or from top to bottom, but it should be explained to the supplier when ordering.

1, 2 and 3 are front and rear valves and bypass valve respectively. 4 is a flowmeter. L2 10D and Lz10D 5D) are the lengths of front and rear straight pipes respectively.D is the nominal diameter of pipes.

How to choose the target flowmeter specification and flow measurement range?

The flow measurement range of the target flowmeter involves many factors, such as structural form, process requirements, working pressure, state flow, etc. After the process flow is determined, since there are multiple flowmeter specifications suitable for the process flow, it is necessary to select a flowmeter with the most suitable specification for the process flow. The specification selection generally follows the following two points:

a. The flowmeter specifications are generally determined according to the process size of the configuration pipeline.

b. Determined according to the flow rate of the measured medium in the measuring tube, the general specification is

Liquid V average = 5m/s

Gas V average = 30m/s

Steam V average = 50m/s

The above medium flow rate is the state flow rate. Under normal conditions, the average state flow rate of the medium is taken as the maximum flow rate of the measured medium passing through the flowmeter. The maximum flow rate that the flowmeter can measure can exceed the maximum flow rate under normal conditions by 1 to 1.5 times.

The following is the flow measurement range of standard water, saturated water vapor and standard dry air flow of various flowmeters under working conditions.