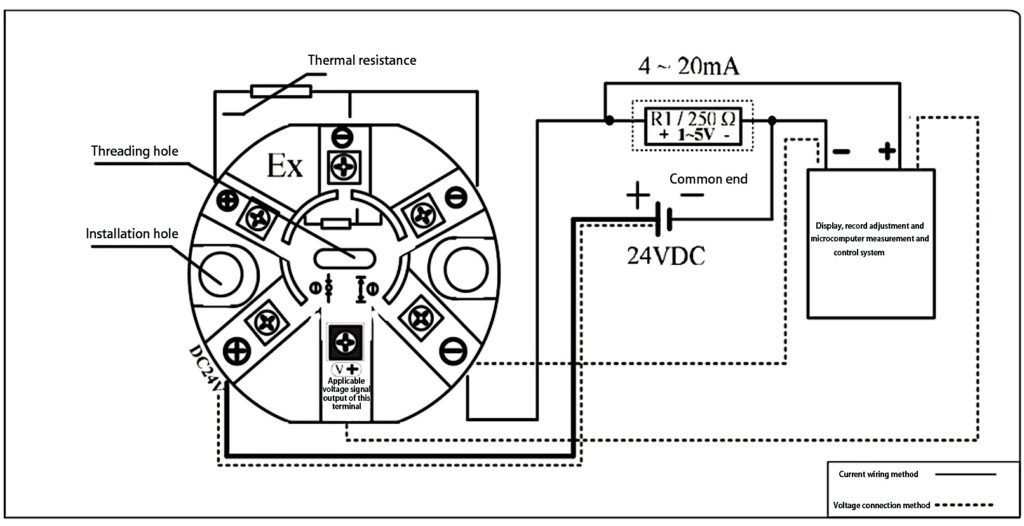

The temperature transmitter adopts thermocouple and thermal resistance as the temperature measuring element. The output signal from the temperature measuring element is sent to the transmitter module. After voltage stabilization filtering, operational amplification, nonlinear correction, V/I conversion, constant current and reverse After protection and other processing, it is converted into 4~20mA, 0-5V/0-10V signal, RS485 digital signal output.

How does a temperature transmitter works ?

The integrated temperature transmitter converts the measured temperature of the thermocouple or thermal resistance sensor into an electrical signal, and then sends the signal to the input network of the transmitter, which includes related circuits such as zero adjustment and thermocouple compensation. The zero-adjusted signal is input to the operational amplifier for signal amplification. One channel of the amplified signal is calculated and processed by the V/I converter and then output as a 4-20mA DC current; the other channel is processed by the A/D converter and displayed on the meter.

There are two linearization circuits for the transmitter, both of which use feedback. The thermal resistance sensor is corrected by positive feedback, and the thermocouple sensor is corrected by the multi-segment broken line approximation method. The integrated digital display temperature transmitter has two display modes. The temperature transmitter displayed by LCD is output in two-wire mode, and the temperature transmitter displayed by LED is output in three-wire mode.

If the transmitter consists of two sensors used to measure the temperature difference, there is a given continuous function relationship between the output signal and the temperature difference. It is called a temperature transmitter, Temperature Transmitter 4-20mA, RTD Temperature Transmitter

What is a smart temperature transmitter?

The intelligent temperature transmitter module is dedicated to high-performance HART protocol temperature transmitter. Support PT50, PT100, PT500, PT1000 four kinds of thermal resistance and E, J, B, K, N, R, S, T eight kinds of thermocouples. It supports the measurement of millivolt signals and resistance signals at the same time. Isolation voltage DC1000V.

What is an integrated RTD temperature transmitter?

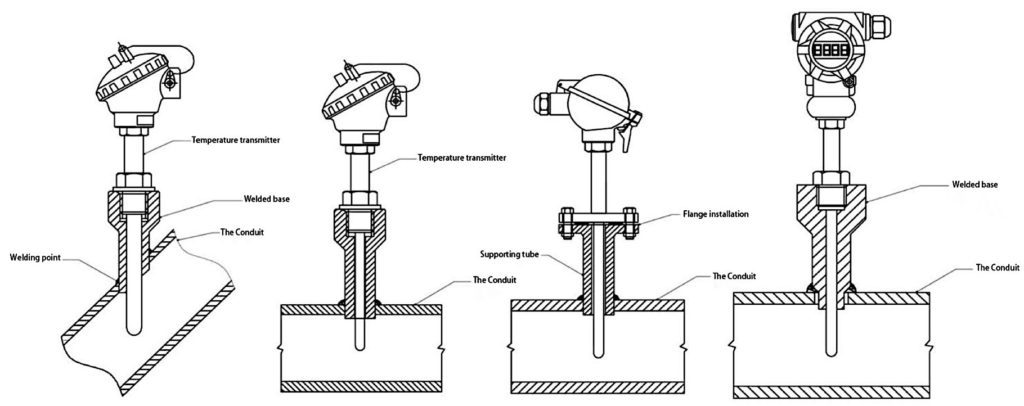

The integrated thermal resistance temperature transmitter is a relatively small temperature transmitter that can be installed in the junction box of the thermal resistance. The integrated temperature transmitter is generally composed of a temperature measuring probe (thermocouple or thermal resistance sensor) and a two-wire solid electronic unit. The temperature probe is directly installed in the junction box in the form of a solid module to form an integrated transmitter. Integrated temperature transmitters are generally divided into two types: thermal resistance and thermocouple.

How to calibrate the temperature transmitter?

The calibration of the transmitter should be carried out 5 minutes after power-on, and pay attention to the ambient temperature at that time. When measuring high temperature (>>100°C), the sensor cavity and the junction box should be separated by filling material to prevent the junction box from being too high to burn out the transmitter. When using the sensor in the case of serious interference, the housing should be firmly grounded to avoid interference, the power supply and signal output should be transmitted by Ф10 shielded cable, and the crimping nut should be tightened to ensure air tightness. The temperature transmitter should be calibrated every 6 months. If the temperature transmitter cannot perform linear correction due to circuit limitations, it is best to select the range according to the instructions to ensure its linearity.

Reasons for inaccurate data display

1. The line is long and the signal is attenuated;

2. Line impedance does not match;

3. The signal is disturbed and not shielded;

Why do temperature transmitters (or analog input cards for temperature input in DCS) need cold junction compensation?

(1) The temperature transmitter is installed on site, and the temperature of the cold end changes with the change of the environment.

(2) When the cold junction is not compensated, the output of the transmitter will be higher than the actual temperature, which will bring wrong judgment to the operator, so cold junction compensation should be performed.

What is a temperature transmitter cold junction compensator? What is the rationale?

The thermocouple reference junction temperature compensator is a device used to automatically compensate the thermocouple measurement value changes due to changes in the reference junction temperature. It is essentially a DC signal millivolt generator that can change with the temperature of the reference terminal. When it is connected in series in the thermocouple measurement circuit to measure the temperature, the temperature of the reference terminal can be automatically compensated.

Application of Integrated temperature transmitter

The temperature transmitter isolates and converts the measured ambient temperature into a single-channel standard DC voltage or DC current output in a linear proportion; temperature transmitters are widely used in petroleum, chemical, chemical fiber; textile, rubber, building materials; electric power, metallurgy, medicine ; On-site temperature measurement process control in food and other industrial fields; especially suitable for computer measurement and control systems, and can also be used with instruments.

Temperature transmitter field installation

1. Before installation, check whether the accessories are complete, whether the fasteners are loose, and tighten the antenna.

2. When installing, pay attention to handle it with care, and do not knock or drop it. The antenna can work normally after tightening it

3. After installation, after power-on, non-operators are prohibited from opening the front cover. If the operator misoperates, it is strictly forbidden to save it, and it can be turned on again after power off.

※Note: As one of the earliest temperature sensor manufacturer, SenTec provide a wide variety temperature measurement solutions, such as Thermal resistance sensor, Thermocouples sensor, thermometer, temperature transmitter, temperature switch etc.

For specific temperature transmitter price, please contact our sales engineer.