Tuning-fork vibrating densitometer with microprocessor-based electronic conversion unit integrating signal processing, calculation and diagnostic functions. In addition to its convincing measurement accuracy and reliability, it can communicate directly with the PC through the RS485 interface. Under the ADView software environment, users can directly perform online node configuration, fault diagnosis and data logging. While measuring density and temperature, it can also calculate basic density, °API, Brix, concentration percentage, mass percentage, volume percentage, specific gravity and other parameters.

Tuning fork density meter can be directly installed on storage tanks and pipelines, and its measured fluid viscosity can be as high as 20000cP, which is a notable feature of its superiority over other similar products, and it also has a very high performance-price ratio.

Where the tuning fork density meter used for ?

Typical industries of tuning fork density meters include petrochemical industry, wine industry, food industry, pharmaceutical industry and mineral processing (such as clay, carbonate, silicate, etc.), which are specifically used for interface detection in multi-product pipelines in the above industries , The density detection of the stirred mixture, the monitoring of the end point of the reactor, and the detection of the interface of the separator.

VIBRATION FORK DENSITOMETER MEASUREMENT PRINCIPLE

The sensor of tuning fork densitometer is designed according to the vibration principle of components. This vibrating element is similar to a tuning fork with two teeth. The fork body vibrates because of a piezoelectric crystal located at the root of the teeth. The frequency of vibration is detected by another piezoelectric crystal. Through phase-shifting and amplification circuit, the fork body is stabilized on the natural resonance frequency. When the medium flows through the fork, the change of resonance frequency is caused by the change of medium quality.

The density and vibration frequency of the medium conform to the following mathematical formula:

D=K0+K1T+K2T2

In the formula: D = density of measured medium, T = natural frequency of the fork, T2= frequency of the measured medium passing through the fork

K0, K1, K2 = constant

According to this formula, the accurate density of the medium can be calculated by the electronic processing unit.

What are the advantages and disadvantages of insertion turing fork density meter?

Advantages of tuning fork density meter: simple installation, plug and play, maintenance-free. The density of mixed media containing solids or air bubbles can be measured.

Disadvantages of Tuning Fork Density Meter: The density meter is not ideal for measuring media that are easy to crystallize and scale.

What is the edge effect measured by a tuning fork densitometer?

Edge effect refers to the distortion of the waveform in the process medium due to reflections from the pipe wall. If the tube wall is within the effective measurement area of the tuning fork densitometer, edge effects can cause inaccurate measurements.

Sentec manufactures tuning fork densitometers calibrated to compensate for edge effects. Tuning Fork Density Meters can be calibrated for free flow, 2″, 2.5″ or 3″ pipe. If the fork densitometer is installed in a pipe that does not match the calibrated specification, the compensation will be inaccurate and the process measurement will be inaccurate. Verify that the pipe size the tuning fork density meter is calibrated to matches the pipe size you plan to use.

How does the flow affect the measurement process of a tuning fork densitometer?

Keep the flow and flow rate constant and within the specified limits of the fork densitometer. The flow of the medium provides a steady flow of heat and into the meter mounting location, the flow affects the self-cleaning at the meter’s tuning fork and the dissipation of air bubbles and solid contaminants around the meter.

If the fork densitometer is installed by-pass (for example, in a flow chamber), a pressure drop device should be used across the baffle in the main process piping, and a pitot spoon or sample pump should be used to maintain flow. When using a sampling pump, place the pump upstream of the meter.

Can the tuning fork density meter be used for slurry measurement?

Yes, it can. For best measurement in the presence of solids:

• Avoid sudden changes in flow rate, which may cause deposits.

• Install the meter far enough downstream from any fittings that may cause centrifugation of solid particles (eg bends).

• Keep the flow rate where the meter is installed within the specified limits.

Vibration fork densitometer installation

Different from the pipeline density sensor, the fork part of the plug-in densimeter is not totally closed.

1. Density meter Pipe wall or vessel installation

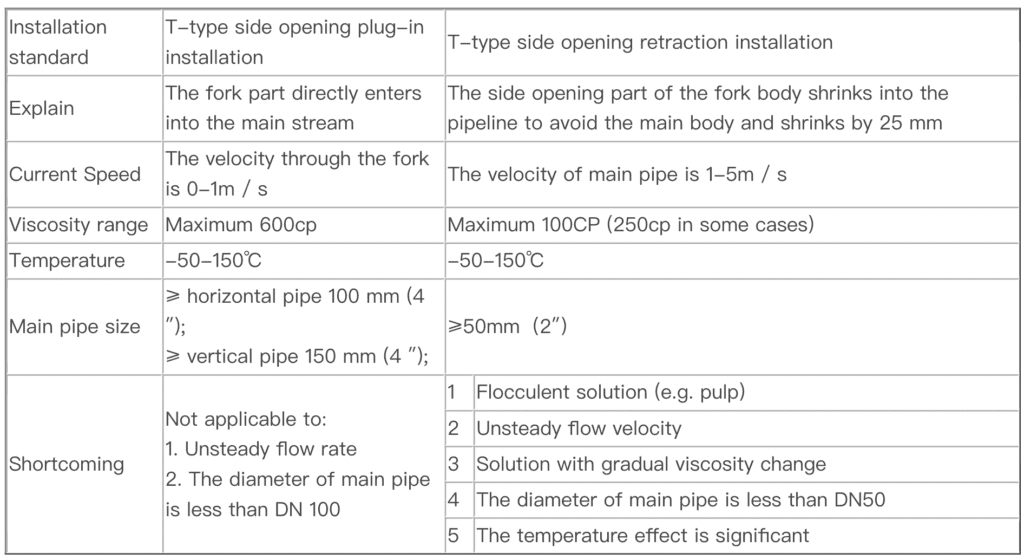

The boundary effect of the wall on the fluid and the viscosity effect of the measuring medium itself will have a certain impact on the measurement and calibration of the sensor. In order to overcome these problems, according to different environments, we set up the installation mode and pipe diameter in advance to facilitate the selection under the same conditions.

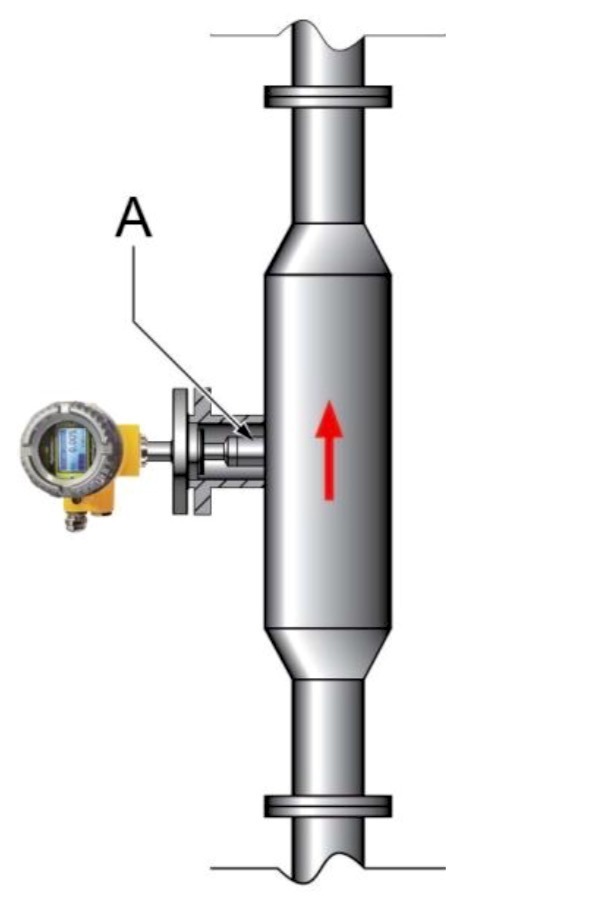

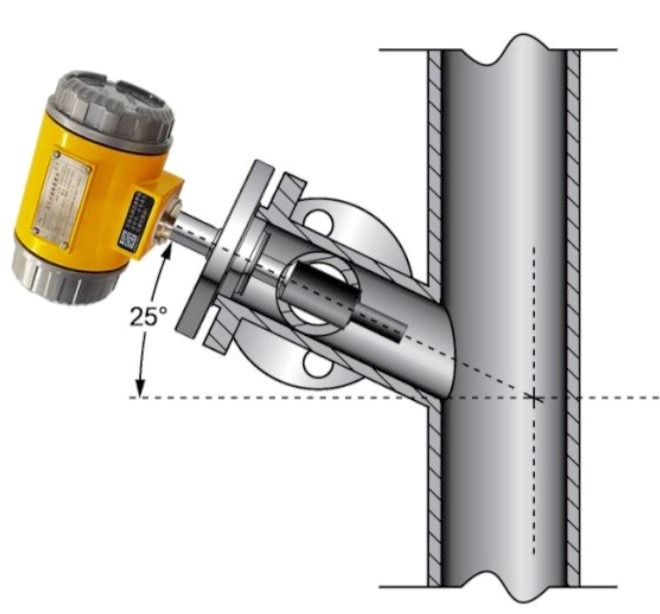

2. Insertion Fork density meter Installation positioning

In order to ensure that the densimeter can measure accurately and display stably, the flow rate of the measured medium shall not be greater than 1 m / s, and the diameter of the pipeline for installing the densimeter shall be greater than or equal to 159 mm. The position for installing the densimeter shall be as far away from the pump as possible, and the distance shall be greater than 5 m. when the flow rate is greater than 1 m / s, the diameter expansion installation shall be adopted, and every 1 m increase in the flow rate shall be adopted, The diameter of the pipeline installed with the densimeter is increased by 1.5 times. There should be a straight pipe section of ≥ 600mm in front of the instrument and a straight pipe section of ≥ 300mm behind the instrument to ensure that the fluid is in a laminar flow state when it flows through the fork, as shown in the figure