Ultrasonic level transmitter also called Ultrasonic level gauge,Anti-corrosion ultrasonic level gauge is a monitoring instrument for measuring liquid height, tank height and material position. The instrument itself can use two-wire, three-wire or four-wire technology. Two-wire system: power supply and signal output are shared; three-wire system: power supply circuit and signal output circuit are independent. When DC 24v power supply is used, a 3-core system can be used The cable, the negative end of the power supply and the negative end of the signal output share one core wire; the four-wire system is: when the AC 220v power supply is used, or when the DC 24v power supply is used, and the power supply circuit and the signal output circuit are required to be completely isolated, a single wire should be used. A 4-conductor cable. DC or AC power supply, with 4~20mADC, high and low switch output.

Measuring range: 0-60 meters, various forms are optional, suitable for various corrosive and chemical occasions, high precision, remote signal output, PLC system monitoring.

The ultrasonic level gauge consists of three parts: ultrasonic transducer (probe), drive circuit (module), and electronic liquid crystal display module.

What is the advantage of ultrasonic level measurement transmitter?

Ultrasonic level transmitter is an ideal measurement tool for corrosive, junctional or acid-base wastewater. Ultrasonic level transmitter can measure the media including hydrochloric acid, sulfuric acid, hydroxide, waste water, resin, paraffin, mud, lye and bleach and other industrial agents.

Compared with other level gauges, Ultrasonic level transmitter also has the following advantages:

*Non-contact measurement.

*No moving parts, simple structure and long service life.

*Corrosion resistance (most of the probes are made of PVDF, PP and other materials).

*Automatic temperature compensation function.

*Not affected by the humidity and viscosity of the medium.

*Not affected by dielectric constant, electrical conductivity, and thermal conductivity of the medium.

Where the ultrasonic level transmitter apply for ?

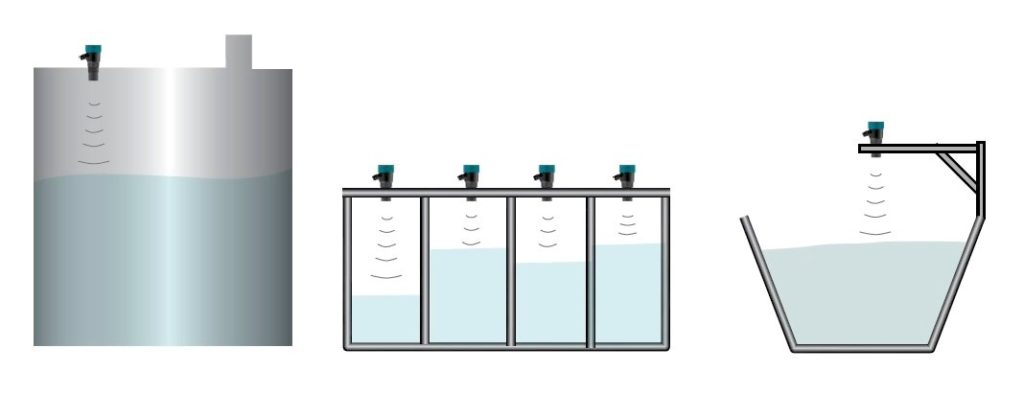

Water and sewage treatment: pump room, water collection well, biochemical reaction tank, sedimentation tank, etc .

Electric power, mining: mortar pool, coal slurry pool, water treatment, etc.

Ultrasonic level transmitter to measure liquid level

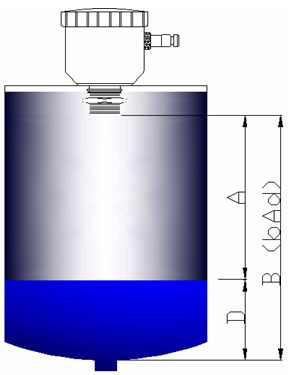

B(Installation Height)is the distance from bottom of container to sensor surface,A is the distance between sensor surface and liquid surface,D is the height of liquid,D= B(Installation Height)-A, display value is bottom of container to liquid surface(D).

*Measure air distance

Set BD =0,display value is distance from sensor surface to liquid surface(A).

Ultrasonic level transmitter installation

When installing an ultrasonic level meter, the blind area of the ultrasonic level meter must be considered. When the liquid level enters the blind zone, the ultrasonic level gauge cannot measure the liquid level. Therefore, when determining the range of the ultrasonic level gauge, a margin of 50 cm must be reserved. When installing, the probe must be 50 cm higher than the maximum liquid level. about. In this way, the accurate monitoring of the liquid level and the safety of the ultrasonic level gauge can be ensured.

In actual use, due to the lack of consideration during installation, the level gauge is completely submerged by water, resulting in complete damage to the level gauge, so the highest level value of the liquid to be measured should be considered.

Attention should be paid to the mechanical installation: the installation should be perpendicular to the surface of the test object, avoid measuring foam objects, and avoid installing the distance from the surface of the measuring object less than the blind spot distance (blind spot: each product will have a standard, which will be known with the product), It should be considered that the beam avoids the blocking material and does not meet the filling opening and the container wall. When detecting large solid objects, the orientation of the probe should be adjusted to reduce the measurement error.