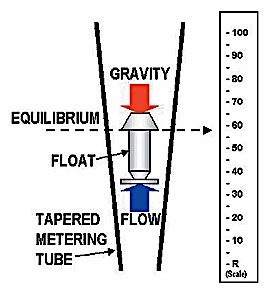

The variable area flow meter measures the fluid flow according to the throttling principle, but it changes the flow area of the fluid to keep the differential pressure above and below the rotor constant, so it is also called a variable flow area constant differential pressure flowmeter, also known as a float flowmeter.

The working principle of the variable area rota flowmeter

The rotameter consists of two parts, one is a conical tube that gradually expands from bottom to top; the other is a rotor that is placed in the conical tube and can move freely up and down along the center line of the tube . When measuring the flow of the fluid, the fluid to be measured flows in from the lower end of the conical tube, and the flow of the fluid impacts the rotor and generates a force on it (the magnitude of this force varies with the flow); when the flow is large enough , the resulting force lifts the rotor and raises it.

At the same time, the measured fluid flows through the annular section between the rotor and the conical tube wall. At this time, there are three forces acting on the rotor: the dynamic pressure of the fluid on the rotor, the buoyancy of the rotor in the fluid and the gravity of the rotor itself. When the flowmeter is installed vertically, the center of gravity of the rotor coincides with the axis of the tapered tube, and the three forces acting on the rotor are in a direction parallel to the tube axis. When the three forces reach equilibrium, the rotor floats smoothly at a certain position in the cone. For a given rotameter, the size and shape of the rotor have been determined, so its buoyancy in the fluid and its own gravity are known to be constant, only the dynamic pressure of the fluid on the float varies with the flow velocity. . Therefore, when the incoming flow velocity becomes larger or smaller, the rotor will move up or down, and the flow cross-sectional area of the corresponding position will also change, until the flow velocity becomes the corresponding speed when the flow rate becomes balanced, and the rotor will be stable at the new position. For a given rotameter, there is a one-to-one correspondence between the position of the rotor in the cone and the flow rate of the fluid through the cone.

types of variable area flow meter

Rotameters can be classified from different angles, such as:

a. According to the material of the tapered tube, it is divided into transparent tapered tube and metal tapered tube.

b. According to whether there is remote signal output, it is divided into local indication type and remote signal output type, the latter is divided into two types: electric shock signal and electric signal.

c. According to the measured fluid, it is divided into liquid, gas and steam.

d. According to the amount of the measured fluid passing through the rotameter, it is divided into full flow type and split flow type.

a. Classification type by conical tube material

(1) Transparent conical tube rotameter: The most used material for transparent conical tube is glass. When the instrument without guide structure is used to measure gas, the glass tube is easily broken; there are also transparent engineering plastics such as polystyrene. , polycarbonate, plexiglass, etc., with the advantage of not easily broken.

(2) Metal tube conical tube rotameter: Compared with transparent conical tube rotameter, it can be used for higher medium temperature and pressure, and there is no potential danger of glass tube rotameter cone being broken. The typical structure is that the tapered tube and the shell are made into an integrated structure, and there are also separate structures in which the tapered tube is sleeved into the shell.

b. According to whether there is a remote signal output classification type

(1) Local indication type float flowmeter: Some transparent tube float flowmeters are mainly based on local indication and are equipped with proximity switches to output the upper and lower limit alarm signals of the flow.

(2) Remote signal output type float flowmeter: The conversion part of the remote signal output type instrument converts the float displacement into a current or air pressure analog signal output, which becomes an electric remote transmission float flowmeter and a gas remote transmission float flowmeter respectively.

c. Classify type by fluid to be tested

It is divided into three types: liquid, gas and steam.

In fact, most of the rotameters can be used for liquid or gas with the same instrument, and the structure is universal. Only floats and conical tubes can be designed separately for gas, which are divided into two series of liquid and gas.

d. Classify the type according to the amount of the measured fluid passing through the rotameter

1) Full flow type, that is, the instrument in which all the fluid to be measured flows through the rotameter

2) Split flow type Compared with the full flow type, only part of the measured fluid flows through the flow detection part such as the float.

What are the advantages and disadvantages of variable area flow meter ?

Rotameters are the most commonly used flowmeters in industry and laboratories. It has the characteristics of simple structure, intuitive, small pressure loss, convenient maintenance and so on. The disadvantage is that it is easily affected by factors such as fluid density, pressure and viscosity. During the flue gas flow test, the area flowmeter cannot be used due to the dust contained in the flue gas.

Advantage of variable area rotameter:

(1) High measurement accuracy;

(2) The installation pipeline conditions have no effect on the measurement accuracy;

(3) It can be used for the measurement of high viscosity liquids;

(4) The range is wide;

(5) The direct-reading instrument can directly obtain the cumulative total without external energy.

Disadvantage of variable area rotameter:

(1) The results are complex and bulky;

(2) The type, caliber and working state of the medium to be tested are relatively limited;

(3) Not suitable for high and low temperature occasions;

(4) Most instruments are only suitable for clean single-phase fluids;

(5) Noise and vibration are generated.

VARIABLE AREA ROTAMETER FLOW METER APPLICATION

Application of variable area bypass rotameter flowmeter:

As an intuitive flow indicator or a field indicating instrument with low measurement accuracy requirements, the rotameter accounts for more than 90% of the application of the rotameter, and is widely used in electric power, petrochemical, chemical, metallurgy, medicine and other process industries and sewage treatment, etc. public utilities. In some applications, as long as the monitoring flow rate does not exceed or does not fall below a certain value, for example, the increase in the flow rate of the cable inert shielding gas indicates that a new leak point has been generated. The glass tube float flowmeter with upper or lower flow alarm can be used in places such as circulating cooling and cultivating tanks for water or air flow reduction and flow interruption alarm. The glass rotor flowmeter has strong corrosion resistance and can detect the flow rate of acid (except hydrofluoric acid), alkali, oxidant and other corrosive gases or liquids. It is suitable for chemical, pharmaceutical, papermaking, sewage treatment and other industries.

Continuous sampling of analytical instruments for environmental protection atmospheric sampling and on-line monitoring of process industries, and flow monitoring of sampling are also the bulk service objects of rotameters.

As an auxiliary instrument for constant flow measurement and control in the measurement of other parameters such as liquid level and density in the process industry, it is widely used and occupies a considerable share.

The remote metal rotameter with signal output is often used as a flow control detection instrument or pipeline mixing ratio in the process industry, such as controlling the ratio of raw water and chemical solution in the water treatment process.

Variable area bypass rotameter flowmeter Installation attention:

Rotameters are used for small pipe diameters and low flow rates. Commonly used instruments have a diameter of 40-50mm or less, and the minimum diameter is 1.5-4mm. It is suitable for measuring low flow rate and small flow rate. Taking liquid as an example, the nominal pipe diameter of the full-scale flow rate of glass tube rotameter with a diameter of less than 10mm, the flow rate is only between 0.2-0.6m/s, or even lower than 0.1m/s; metal The tube rotameter and the glass tube rotameter with a diameter larger than 15mm are slightly higher, and the flow rate is between 0.5-1.5m/s.

Float flowmeter can be used for lower Reynolds number, choose a float with insensitive shape of viscosity, as long as the Reynolds number at the circulating annular gap is greater than 40 or 500, the flow coefficient of the change of Reynolds number remains constant, that is, the change of fluid viscosity does not affect the flow coefficient. This value is far lower than the minimum Reynolds number of 104-105 required for throttling differential pressure instruments such as standard orifice plates.

Most rotameters do not have requirements for upstream straight pipe sections, or they do not have high requirements for upstream straight pipe sections.

The float flowmeter has a wide flow range, generally 10:1, the lowest is 5:1, and the highest is 25:1. The output of the flow sensing element is nearly linear. Pressure loss is low.

The glass tube rotameter has a simple structure and low price. As long as it is convenient for those who indicate the flow in the field, the disadvantage is that there is a risk that the glass tube will be fragile, especially the non-guided structure float is used for gas.

Metal tube rotameters have no risk of cone breakage. Compared with glass tube rotameters, the operating temperature and pressure range is wide.

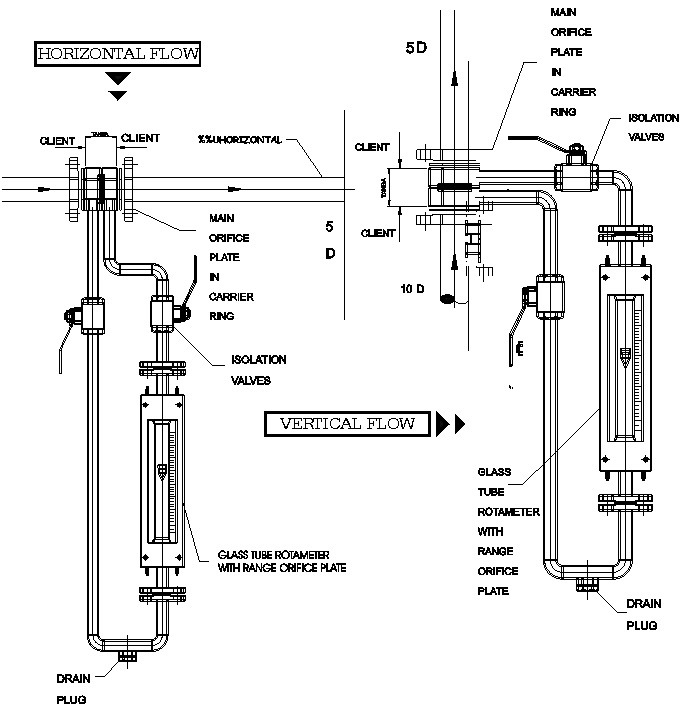

Most structural rotameters can only be used in pipeline installations with bottom-up vertical flow.

The application of rotameter is limited to small and medium pipe diameters. Ordinary full-flow rotameter cannot be used for large pipe diameters. The maximum diameter of glass tube rotameter is 100mm, and the metal tube rotameter is 150mm. Larger diameters can only be used for split flow type. meter.

When the fluid used is different from the factory calibration fluid, the flow indication value should be corrected. The rotameter for liquid is usually calibrated with water, and the gas is calibrated with air. If the density and viscosity of the actual fluid used are different, the flow rate should deviate from the original graduation value and should be converted and corrected.

How to order variable area flowmeter ?

The main measurement object of the rotameter is a single-phase liquid or gas, and the liquid containing particulate solids or the gas containing droplets is usually not applicable. Because the float adheres to particles or tiny air bubbles in the liquid flow, it will affect the measurement value. Rotameter order and installation attentions:

1. For the selection of the metal tube float rotameter of the remote transmission type, it is necessary to select the rotameter suitable for the explosion-proof type of the place of use;

2. For places where the temperature of the measured medium is too high (>120°C) or too low, it is usually necessary to take heat preservation or heat insulation measures for the sensor part of the rotameter. In order to ensure that the signal converter – indicator is normal The working ambient temperature should choose a high temperature indicator.

3. For some measured media that need to be kept warm or cooled, a jacketed rotameter should be selected.

4. For the unstable pressure of the inlet medium of the rotor flowmeter, especially for gas measurement, in order to ensure the accuracy and service life, a damping structure should be selected.

5. The pressure level required for the medium is higher. When the pressure level exceeds the standard pressure level, please select the high-pressure type structure when selecting the type.

6. When installing the rotameter, ensure that the verticality of the measuring tube is better than 5%, and a bypass should be installed to facilitate maintenance and cleaning without affecting production.

7. The position where the rotameter is installed should ensure that the inlet has a straight pipe section of ≥5DN, and the outlet is not ≤250mm of straight pipe; if the medium contains ferromagnetic substances, a magnetic filter should be installed in front of the rotameter.

8. The control valve in the measurement and control system should be installed downstream of the rotameter. When used for gas measurement, the working pressure should be ensured not less than 5 times the pressure loss of the rotameter, so that the rotameter can work stably.

9. Before installing the metal pipe float rotameter, the welding slag in the pipeline should be purged; during installation, take out the stopper element in the rotameter; when using it after installation, slowly open the control valve to avoid impact damage to the rotor flow count.