Magnetic Flow Meter is a flow meter that measures the flow of conductive fluids. Abbreviated as EMF, also called Electromagnetic flow meters. It is a kind of Volumetric flow meter. A magnetic flow meter measures the velocity of conductive liquids moving through a pipe or conduit. In the wastewater treatment industry, Magnetic Flow Meter is the best flow meter choice.

Electromagnetic flowmeter measuring principle

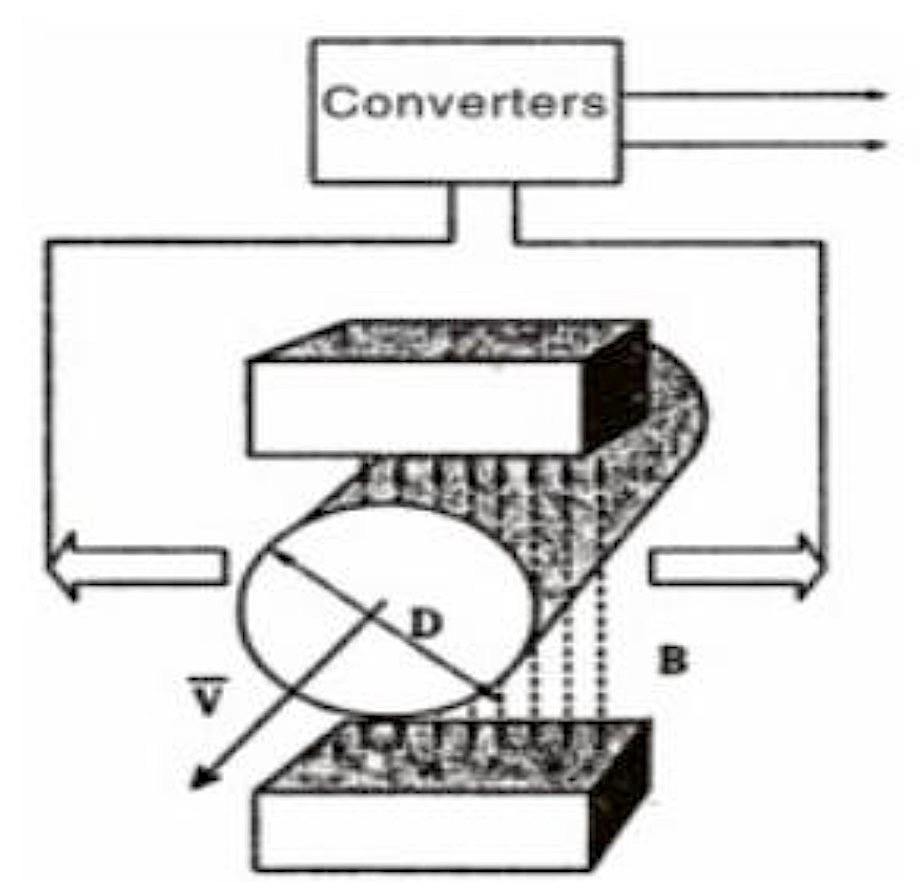

The measuring principle of the electromagnetic flowmeter sensor is based on Faraday’s law of electromagnetic induction. A pair of detecting electrodes are mounted on the wall of the tube perpendicular to the axis of the measuring tube and the magnetic field lines of the magnetic field. When the conductive liquid moves along the axis of the measuring tube, the conductive liquid acts as cutting magnetic line.

An induced potential is generated, which is detected by two electrodes on the measuring tube, and the magnitude is: E=K·B·V·D

Where: E – induced potential

K — meter constant

B – magnetic induction

V—measuring the average flow velocity in the cross section of the tube D—the inner diameter of the measuring tube

When measuring the fluid, the fluid flows through a magnetic field perpendicular to the direction of flow. The flow of the conductive fluid induces a potential proportional to the average flow rate, thus requiring that the conductivity of the flowing liquid being measured be above the minimum conductivity. The induced voltage signal is detected by two electrodes and transmitted to the converter through the cable. After signal processing and correlation calculation, the accumulated flow rate and instantaneous flow rate are displayed on the display screen of the converter.

Where electromagnetic flow meter used for ?

Magnetic flowmeters are used in water treatment plants to measure treated and untreated sewage, process water, water, and chemicals.

Water and wastewater applications include the custody and transfer of liquids in the main pipe between water/wastewater areas.

Applications in the mining and mineral processing industries include process water and process slurry streams and heavy media streams.

In order of usage, water/wastewater industry, chemical, food and beverage, oil and gas (although not for oil and gas fluids but in support of the processes), power, pulp and paper, metals and mining, and pharmaceutical.

Magnetic Water Flow Meter Applications:

FME800 electromagnetic water flowmeter can be used to measure the volume flow of conductive fluid in a closed pipeline. It is widely applied in the flow measurement and control in the fields of chemical and petroleum industry, metallurgy industry, water and wastewater, agriculture and irrigation, paper making, food and beverage industry and pharmaceutical industry.

The premise of using Magnetic Water Flow Meter is that the measured liquid must be conductive. The conductivity of the liquid cannot be lower than the threshold, the lower limit. If the conductivity is lower than the threshold, it will cause measurement error until it can not be used.

It can be measured even if the value exceeds the threshold, and the indication error does not change much. The threshold value of general electromagnetic flowmeter is between 10-4~(5×10-6)S/cm, depending on the model. It also depends on the length of the flow signal line between the sensor and the converter and its distributed capacitance. The product manual usually stipulates the signal line length corresponding to the conductivity.

Electromagnetic Flowmeter Application case:

1.Magnetic Water Flow Meter to Measure Waste Water

The sewage treatment process is mainly through biological oxidation, flocculation, precipitation and other processes to achieve the purpose of sewage purification. At each stage, a certain gauge is needed to measure.

In the sewage industry, according to the characteristics of the corrosiveness, abrasiveness, temperature and condensation of the tested substance and the price tolerance. Different lining and electrode materials should be selected.

In the sewage treatment process, it is necessary to configure corresponding detection instruments according to the process requirements to form a reliable control system.

2.Magnetic Water Flow Meter to Measure Industrial Water

The conductivity of industrial water and its aqueous solution is greater than 10-4S/cm. The conductivity of acid, alkali and salt solution is between 10-4~10-1S/cm, so there is no problem in use. Low distilled water is 10-5S/cm and there is no problem.

The electromagnetic flowmeter cannot measure liquids with very low conductivity. Such as petroleum products and organic solvents. Cannot measure gas, steam and liquids containing more and larger bubbles.

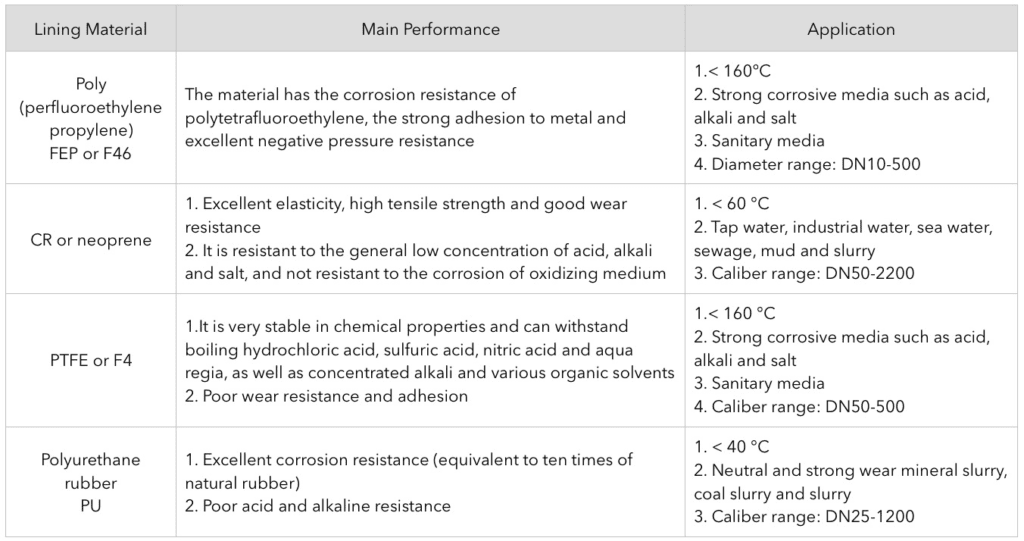

Magnetic flowmeter lining material specification:

The lining material should be selected according to the corrosiveness, abrasiveness and temperature of the measured medium

How to Select the Diameter and Range of Electromagnetic Flowmeter ?

Selection of Diameter and Range of Electromagnetic Flowmeter

The diameter of the transmitter is usually the same as that of the piping system. If the channel dividing system is to be designed, the caliber can be selected according to the range of the flow mother and the flow rate. For electromagnetic flowmeters, the flow velocity is more suitable at 2-4m/s. In special cases. If there are solid particles in the liquid, considering the wear condition, the commonly used flow velocity can be ≤3m/s. For the fluid that is easy to attach to the pipe wall, the flow velocity can be selected ≤2m/s. After the flow velocity is determined, it can be selected according to Qv=π/4D2U to determine the diameter of the transmitter.

The range of the transmitter can be selected according to two principles: one is that the full scale of the instrument is greater than the expected maximum flow value, and the other is that the normal flow value is greater than 50% of the full scale of the instrument to ensure a certain measurement accuracy.

How to choose a suitable electromagnetic flowmeter ?

Magnetic flow meter selection:

1. Understand the process parameters

(1) Know the name of the liquid to be tested (provided by the user)

(2) Understand the maximum flow, common flow, and minimum flow of the liquid to be measured (provided by the user)

(3) Understand the process pipe diameter (provided by the user)

(4) Understand the medium temperature (provided by the user)

(5) Understand the medium pressure (provided by the user)

(6) Understand the conductivity of the fluid to be measured (provided by the user)

(7) Find out if there is negative pressure (provided by the user)

2. Preliminary confirm types of magnetic flowmeter

(1) According to the name and properties of the measured medium, determine whether to use an electromagnetic flowmeter

Note: Electromagnetic flowmeters can only measure the flow of conductive liquids, while gases, oils and most organic liquids are not examples of general conductive liquids

(2) Determine the electrode material according to the learned properties of the medium

Note: The company generally provides four kinds of electrodes, such as stainless steel, Hastelloy, titanium and tantalum. Which electrode should be selected should be checked according to the properties of the medium.

(2) Determine whether to use rubber or PTFE lining according to the learned medium temperature

Note: The temperature resistance of rubber shall not exceed 80C;

Teflon temperature resistance 150C, instant 180C resistance;

Urban sewage can generally use rubber lining and stainless steel electrodes

(3) According to the learned medium pressure, select the flange specification of the meter body

Note: The specification of electromagnetic flange is usually when the diameter is from DN10-250, the rated pressure of the flange is less than or equal to 1.6Mpa;

When the diameter is from DN250-1000, the flange rated pressure is less than or equal to 1.0Mpa;

When the actual pressure of the medium is higher than the corresponding range of the above pipe diameter-pressure, it is a special order, but the maximum pressure shall not exceed 6.4Mpa

(4) Determine the conductivity of the medium

Notice:

(1) The conductivity of the electromagnetic flowmeter shall not be lower than 5uS/cm

(2) The conductivity of tap water is about tens to hundreds of uS/cm. Generally, boiler soft water (deionized water) is conductive, and pure water (highly distilled water) is not conductive.

(3) The electrical conductivity of gas, oil and most organic liquids is much lower than 5uS/cm, which is non-conductive.

How to install the electromagnetic flowmeter ?

Magnetic flowmeter installation guidelines:

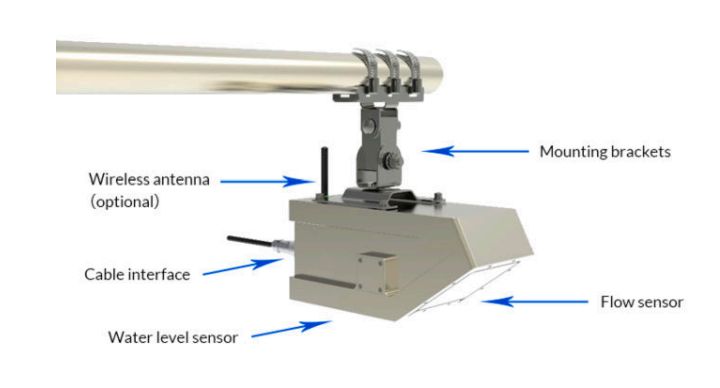

The electromagnetic flowmeter is simply composed of a flow sensor transmitter. The installation requirements of the electromagnetic flowmeter must be installed at the lowest point of the pipeline or the vertical section of the pipeline, but it must be in the case of full pipelines. usage and accuracy requirements.

The measurement principle of the electromagnetic flowmeter does not depend on the characteristics of the flow. If there is a certain amount of turbulence and eddy in the pipeline in the non-measurement area (such as elbows, tangential flow restrictors or a half-open stop valve upstream), it will be the same as the measurement. It doesn’t matter. If there is a steady eddy current in the measurement area, it will affect the stability and accuracy of the measurement. At this time, some measures should be taken to stabilize the flow velocity distribution:

1. Increase the length of the front and rear straight pipe sections

2. Use a flow stabilizer

3. Reduce the cross section of the measuring point.

※Note: As one of the earliest flow meter manufacturer, SenTec provide a wide variety flow measurement solutions, such as differential pressure flow meters, Calorimetric Flowmeter, liquid flow sensor, Ultrasonic Level Transmitter, mass flow meter, Variable Area Flowmeter or Rotameter, Electromagnetic Flowmeter,Turbine Flowmeter,Vortex Flow Meter,Thermal Flowmeter,Coriolis Flowmeter,Mass Flowmeters,Open Channel Flowmeters etc.

For specific Electromagnetic Flowmeter price, please contact our sales engineer.