The float level switch is a kind of level switch. The float level switch uses magnetic force to operate. No mechanical connections. The operation is simple and reliable. When the float switch floats the measured medium, the float moves the main body. At the same time, the magnet on the other end of the float will control the magnet on the switch action lever.

How does a float level switch work ?

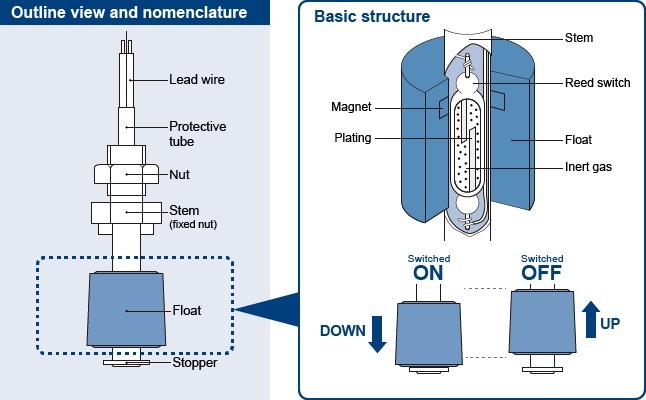

The float ball level switch structure is mainly designed and produced based on the principles of buoyancy and static magnetic fields. The position of the floating ball with a magnet (floating ball for short) in the measured medium is affected by buoyancy. The change of the liquid level causes the position of the magnetic float to change. The magnet in the float and the sensor (reed switch) function to generate a switching signal.

Similar to the principle of the float level sensor. But the float level sensor outputs a quasi-continuous electrical signal, while the float level switch outputs a discrete switching signal.

The float level controller is composed of a float ball and a plunger. It is installed on the top of the container through the connecting flange. The float ball floats on the liquid surface according to the principle of equal volume of the discharged liquid. When the liquid level of the container changes, the float ball also moves up and down. Due to the magnetic effect, the float ball liquid level controller The dry reed is magnetically attracted, and the liquid level position is changed into an electrical signal. The actual position of the liquid is displayed digitally through the display instrument, and the floating ball liquid level controller can achieve long-distance detection and control of the liquid level.

According to the different output signals and functions, the float level sensor can be divided into three categories, float level gauge, float level switch, float level controller.

Float level gauge VS Float level switch VS float level controller

What the difference among the float level gauge, float level switch, float level controller ? According to the different output signals and realized functions, we usually called the float level sensor, as float level gauge, float level switch or float level controller. Actually, they have same working principle. For make it more clear, you can refer following.

1.Float level gauge

The float level gauge uses a magnetic float as the measuring element. Through magnetic coupling, the internal resistance of the sensor changes linearly, and the resistance change is converted into a 4~20mA standard current signal by an intelligent converter, which can display the percentage of liquid level, 4~20mA current and liquid level value, the remote supply control room can realize automatic detection, control and recording of liquid level.

2. Float level switch

The magnetic float of the floating ball liquid level switch is used to rise or fall with the liquid level, so that the reed switch chip at the set position in the sensor detection tube is moved, and the contact opening (closing) conversion signal is sent out.

One or more reed switches are installed in a closed non-magnetically conductive tube, and then the tube is passed through one or more floating balls with a ring magnet inside. The rise or fall of the liquid will drive the floating balls to move up and down together. Thereby, the reed switch in the non-magnetic tube can be turned on or off, thereby outputting a switch signal.

3. Float level controller

The float level controller is suitable for liquid control of liquids in various containers. When the liquid level reaches the upper and lower switching values, the controller contacts send out on-off switch signals. The product series is divided into two categories: explosion-proof and non-explosion-proof. The controller is not suitable for the medium that has strong corrosive effect on brass, stainless steel and other materials and contains magnetically conductive impurities.

What is a Continuous Float Level Sensors ?

Continuous Liquid Level (interface) Measurement and Automatic Control. Explosion-proof and water proof.

Float Level Switches & Sensors with Magnetic Reed Switches for Continuous Level Measurement.

Continuous Float level sensor (float switch) is one type continuous level sensor for industrial level measurement. Float level sensor has a magnetic float that rises and falls as liquid level changes. The percentage of the liquid level, 4 ~ 20mA current and liquid level value, can be displayed on site. Applications like: water tank, fuel tank, level measurement and level control. Vertical, horizontal, and side mounted, all can be satisfied.

FLOAT LEVEL METER APPLICATION

The float level gauge (switch) has the characteristics of simple structure, convenient debugging, good reliability and high precision. The float level gauge can be widely used for continuous measurement of liquid level (interface) of high temperature, high pressure, viscous, dirty medium, asphalt, wax-containing oil, and flammable, explosive, corrosive and other media. The float level gauge (switch) can be used for industrial level measurement and control of various liquid tanks such as petroleum, chemical raw material storage, industrial process, biochemical, pharmaceutical, food and beverage, tank farm management and gas station underground storage. The float level gauge is also suitable for dam water level, reservoir water level monitoring and sewage treatment, etc.

It has been widely used in shipbuilding, papermaking, printing, generator equipment, petrochemical industry, food industry, water treatment, electrician, dye industry, hydraulic machinery and so on. The float switch is a liquid level control device with simple structure, convenient use, safety and reliability. It has smaller volume, faster speed and longer service life than general mechanical switches Features.

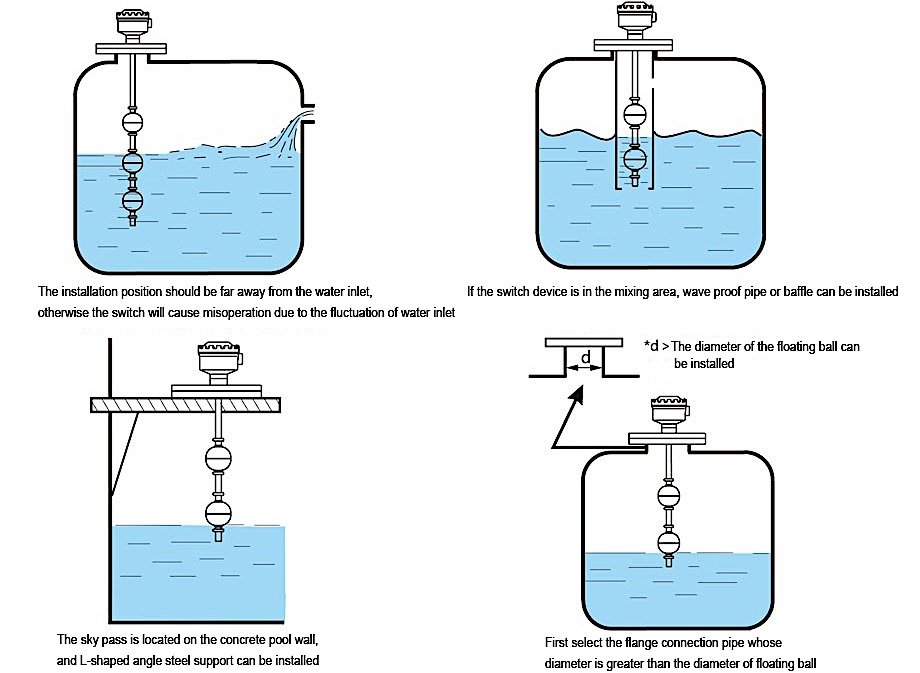

Float level switch sensor installation Applications:

How a float level sensor worked to control water or fuel tank level ?

Float level sensor for water tank & fuel tank:

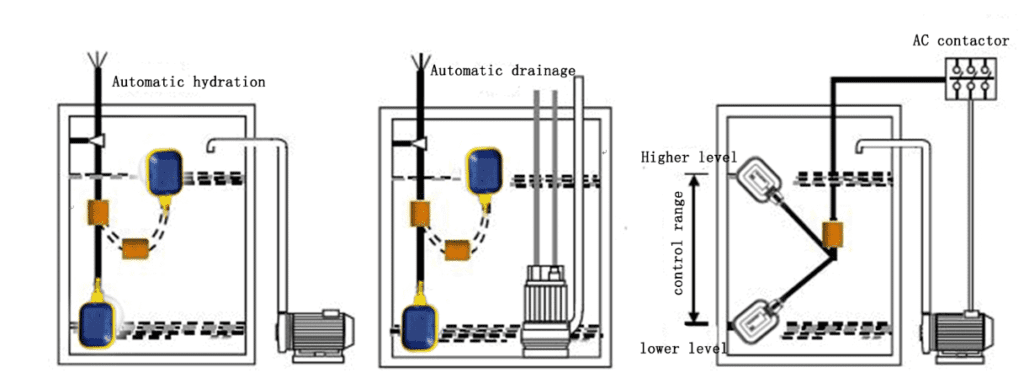

In water treatment, the water tank float level switch is directly related to the safety and reliability of the entire process.

In the water tank, there are high and low level switches. The high level switch can detect whether the water tank is full. If it is full, the water production will stop. The low level switch is used to detect the water tank Is the water sufficient? If it is not enough, no more water can be sent out.

Water tank float level switch is a working condition. If it is a large water tank, other level gauges can also be used to solve it. Like radar level gauges, ultrasonic level gauges, etc.

Of course, our float level sensor can also be used to measure and control the level of the fuel tank.

If it is used in an oil tank, special conditions such as the type of oil and corrosiveness need to be considered.

If you need to measure the level of the fuel tank, please feel free to contact us to get Float level sensor price directly.

※Note: As one of the earlier float level switch sensor manufacturer, SenTec provide A wide variety of float level switch gauge for tank level measurement solutions.

For specific float level switch Sensor price, please contact our sales engineer.