Fuel Oil volume level sensor is based on the principle of radio frequency capacitance measurement and adopts a unique technology to realize automatic calibration.

What is a capacitive fuel oil level sensor?

Capacitive fuel oil level sensor also called Capacitive fuel oil level gauge is a part that detects the position (height) of the oil in the container by using the change of the capacitance between the sensor housing and the sensing electrode after the oil enters the container, and converts this change into a current change.

Fuel Oil Volume Level Sensor working principle

The sensing part of the capacitive oil level sensor is a coaxial container. When the oil enters the container, the capacitance between the sensor housing and the sensing electrode changes. This change is converted by the circuit and performs accurate linear and temperature compensation. , output 4-20mA standard signal supply display instrument. The outer metal tube of the sensor and the central probe constitute a coaxial capacitor. There is a gap between the two. The liquid to be measured enters this gap. Because the dielectric constant of the liquid and air is very different, the level of the liquid changes the capacitance of the capacitor. Capacity, the change of this electric capacity directly reflects the change of the liquid level. This change is processed by the circuit and the program, and the standard signal corresponding to the level of the liquid is output.

What are the capacitive fuel oil level transmitter typical model type?

1. Compact oil level sensor industrial grade, suitable for measurement of oil below 5MPA and temperature below 200°C with low viscosity and low oil quality, and can be attached with various protocols for communication;

2. The vehicle-specific oil level sensor is suitable for the measurement of various fuel oils under normal temperature and pressure. The output damping time is adjustable from 30 to 180s, and it can carry 485 communication;

3. The standard oil level sensor is industrial grade, suitable for the measurement of viscous oil below 5MPA and the temperature below 200℃, and can be attached to various protocols for communication;

4. The high temperature and high pressure oil level sensor is industrial grade, suitable for the measurement of various oil quality below 32MPA and temperature below 250 °C, and can be attached to various protocols for communication;

5. The general-purpose oil level sensor is suitable for the measurement of various fuel oil and hydraulic oil under normal temperature and pressure, and can carry 485 communication.

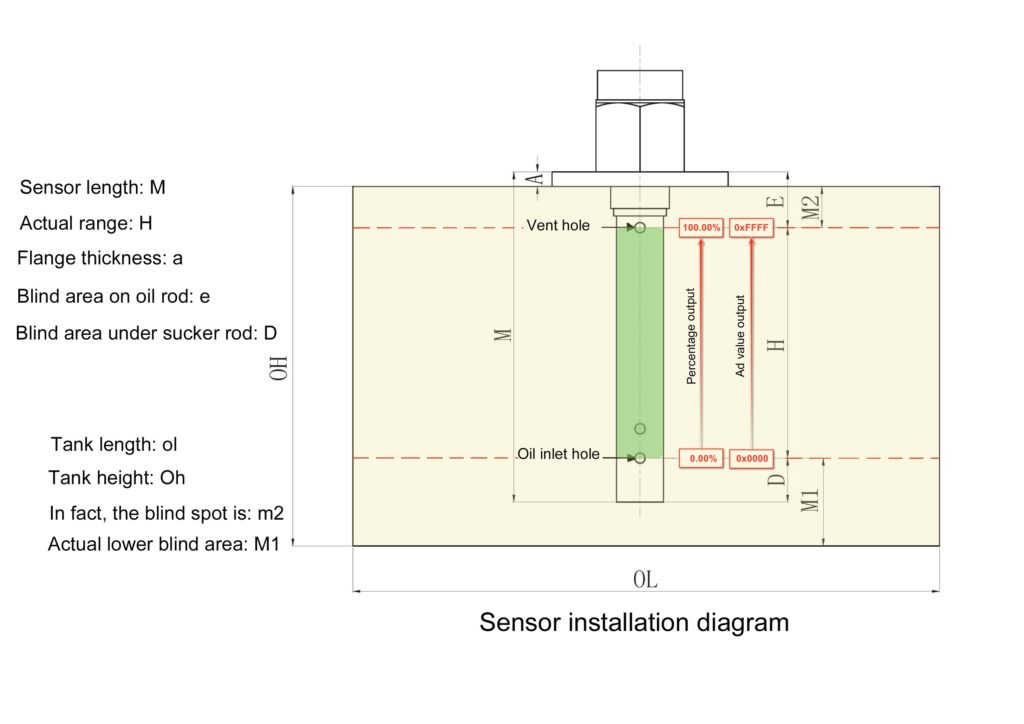

Capacitance fuel oil Level installation diagram

What are the Vehicle fuel consumption management system functions?

10 System functions of Capacitive fuel oil level sensor Vehicle fuel consumption management system:

1. Real-time monitoring of remote fuel consumption

2. Accurate display of remaining fuel

3. Comparison of fuel consumption during the period

4. Time fuel consumption statistics

5. Mileage and fuel consumption statistics

6. Oil spill statistics:

7. Immediate alarm for oil leakage

8. Refueling statistics

9. Refueling real-time display

10. Idle fuel consumption statistics

Vehicle fuel consumption management system of Capacitance fuel oil Level sensor application

*Standardize the driving behavior of drivers to prevent oil theft, oil leakage, detours, and illegal activities;

*Standardize vehicle management, prevent private use of public vehicles, and reduce expenses;

*Accurately measure the refueling status of vehicles to prevent shortcomings;

*Refined management to effectively evaluate the fuel consumption of vehicles in various environments and the energy-saving level of drivers in driving;

*Accurately measure the fuel consumption of a vehicle per 100 kilometers.

Capacitive fuel oil level sensor System advantages

Intelligent: The sensor calculates by itself, reports the fuel volume, fuel volume alarm, and fuel leak volume alarm, without platform processing;

Accuracy: The sensor collects hundreds of times per second, and the amount of data is large. The real data is filtered in real time at the first time, and the shaking during driving can be filtered out and repaired, and the calculated oil volume data is more accurate;

Cooperation: The vehicle-mounted terminal sends the real-time vehicle status (total mileage, ACC status, vehicle speed) to the sensor, and the sensor adjusts the algorithm and parameters according to the vehicle status to improve accuracy.

Timely: report the fuel filling amount and oil leakage in time, and report the oil leakage alarm within 15 seconds of the oil leakage;

Easy to use: platform calculus calculates the fuel tank fuel quantity array, and then sends the sensor; provides three calibration modes: real-time correction, real-time calibration, and retrospective correction;

Linkage: When the oil leaks, the sound and light alarm can be linked on the spot, and the remote oil leak process can be linked to video;

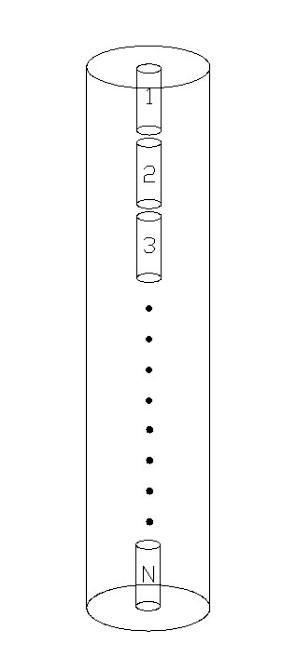

Variety: can detect single fuel tank, double fuel tank, three fuel tank, four fuel tank…

Sample report

Fuel quantity report: Fuel quantity statistics is a report module that counts the fuel quantity, mileage, speed, fuel temperature, ambient temperature, air conditioning and ACC status of the monitored objects connected to the fuel level sensor over a period of time

Refueling data: display all refueling data of the monitored object during the query time period

Oil spill data: display all the oil spill data of the monitored object during the query time period

How to installation a oil volume level sensor ?

Operating procedures

First: put the gasoline clean, then rinse it with water two to three times, and install it according to the following steps.

1. Positioning

The principle is generally in the middle of the fuel tank, avoiding the position of the original oil float.

2. Clean the dirt at the opening of the fuel tank

Remove the oil stains on the location where the fuel tank is to be installed

3. Drill through

Clamp a 50mm metal hole drill with a pistol drill, connect the power supply and drill in the middle of the positioned fuel tank, (note that the speed is not fast, stop when it is about to drill through, and peel off the metal to be drilled with a screwdriver and needle-nose pliers down to avoid it falling into the tank)

4. Clean up

Use a shrink file to remove the burrs from the opening

Use a magnet with a wire to put it in the fuel tank and suck out the iron chip.

5. Take out the sensor customized by the manufacturer according to the vehicle model

Remove the protective cover of the float and remove the 5 mounting screws and 5 self-tapping screws with a screwdriver.

Separate the sensor from the mounting flange.

Check flange O-rings. If it is complete, place it on the open hole.

6. Fixed

Use a pistol drill to clamp a 2mm drill bit, and drill holes in the 5 grooved holes of the mounting flange (to penetrate the fuel tank), put metal sealant on the 5 self-tapping screws respectively, and fasten the flange to the fuel tank. superior. Mount the sensor on the flange and tighten with 5 screws.

7. Seal

Use metal sealant to seal the flange and tank junction once.

8. Wiring

Connect the corresponding colored wires, and wrap the joints with black tape. Best line with casing. To run the line, go to the beam on the car.

※Note: As one of the earlier Capacitive Level measurement manufacturer, SenTec provide A wide variety of Capacitive fuel oil Sensors for tank level measurement solutions.

For specific Capacitive oil level sensor price, please contact our sales engineer.