Micropower impulse radar (MIR) combines time domain reflectometry (TDR), equivalent time sampling (ETS), and modern low power circuitry.This synthesis of technologies creates a high-speed Guided Wave Radar (GWR) transmitter.

What is a guided wave radar level transmitter?

Guided wave radar devices, also called wave-guided radar level transmitters.

Have no moving parts and require minimum maintenance.

They can measure both levels and the interface between two media.

The guided wave radar level sensor is applied to water storage tanksacid and alkali storage tanks, slurry storage tanks,

solid particles, and small oil storage tanks.

All kinds of conductive, non-conductive media, corrosive media.

Such as coal bunkers, ash silos, oil tanks, acid tanks, etc.

GWR LEVEL TRANSMITTER WORKING PRINCIPLE

Guided wave radar is a kind of measuring instrument based on the principle of time travel. Radar wave runs at the speed of light, and running time can be converted into a level signal by electronic components. The probe sends out high-frequency pulse and spreads along cable type or rod-type probe. When pulse meets the surface of material, it reflects back and is received by receiver inside the meter, and converts distance signal into level signal.

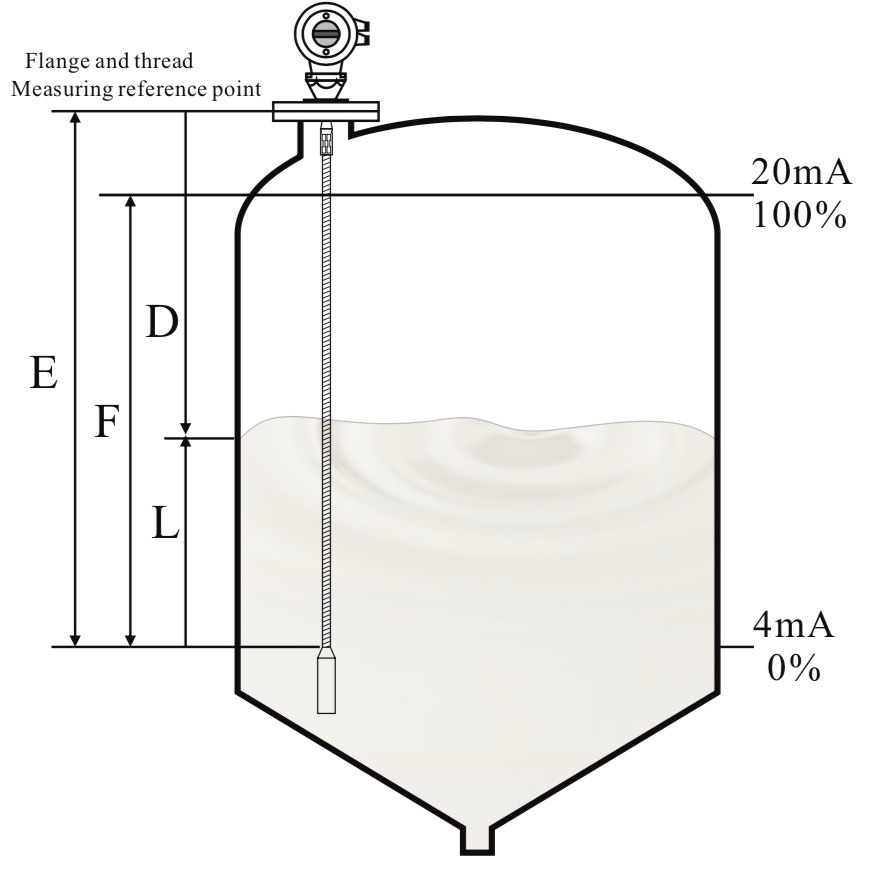

D: the distance to material surface, and T:pulse travel time, are proportional:

D=C×T/2

Where C is the speed of light. Because the empty distance E is known, the level L is: L=E-D

By entering the empty height of E (= zero), full tank height F (= hundred) and the application to set some parameters, application parameters will automatically adapt the instrument to measure the environment, corresponding to the 4-20mA output.

Guide wave level sensor Measurement Range:

Symbol explanation:

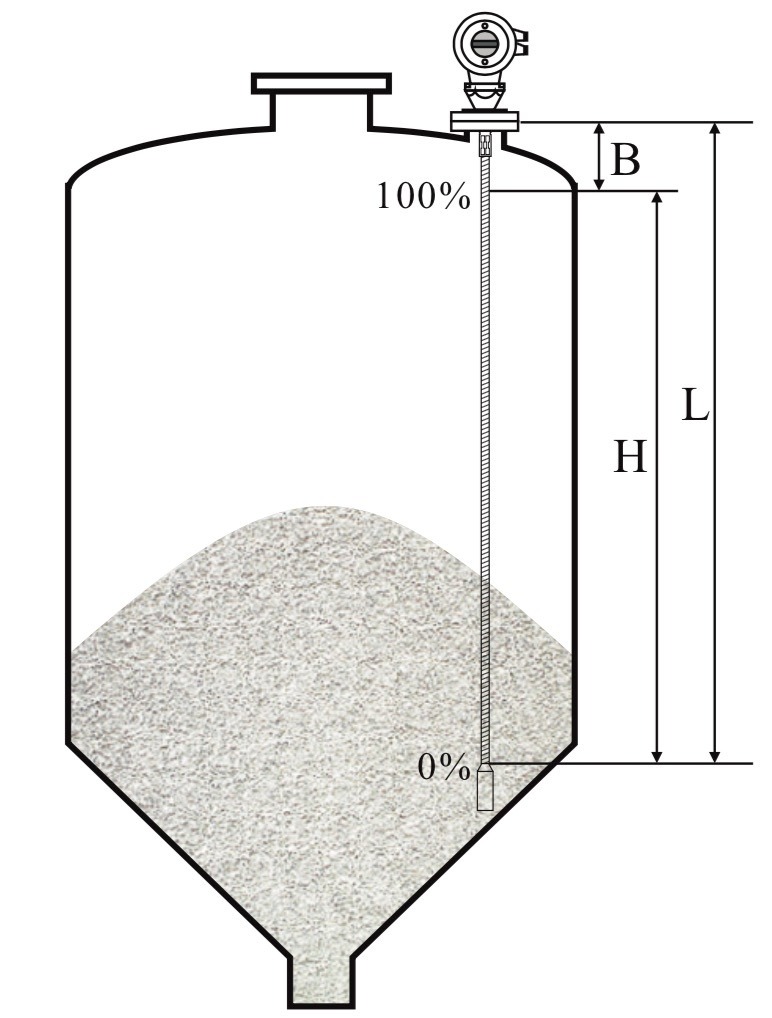

H—- Measurement range

L—- Empty tank distance

B—- The blind at the top

E—- The minimum distance between the probe and the

tank wall

— The top blind area refers to the minimum distance between highest level of material and measuring reference point.

— The bottom blind area refers to the distance that cannot be

How to choose Radar Corrosive Liquid Chemical Level Sensor ?

Liquid Chemical Level Sensor works for level measure and monitor of corrosive liquids for Chemical Processing. The level measurement of corrosive chemicals places extremely high demands on the sensor. Downtime must be avoided. The radar liquid level sensor wrapped in PTFE is corrosion resistant and has a long service life. The sensor has both analog and digital outputs that comply with industry standards. SenTec Radar Corrosive Liquid Chemical Level Sensor antenna has been further optimized and is suitable for the measurement of various corrosive liquids, which are desire products for Corrosive Liquid Chemical Level Sensor in Chemical Processing etc.

For Guided wave radar level transmitter price. please contact our sales engineer.

How to install a guided wave radar level meter?

Reasonable meter installation to ensure long-term reliable and accurate measurement .

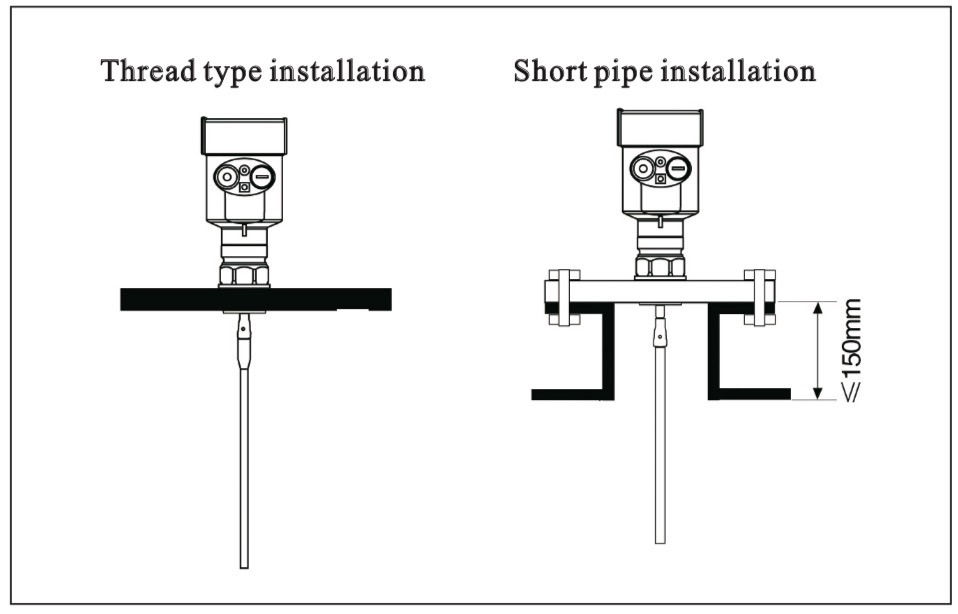

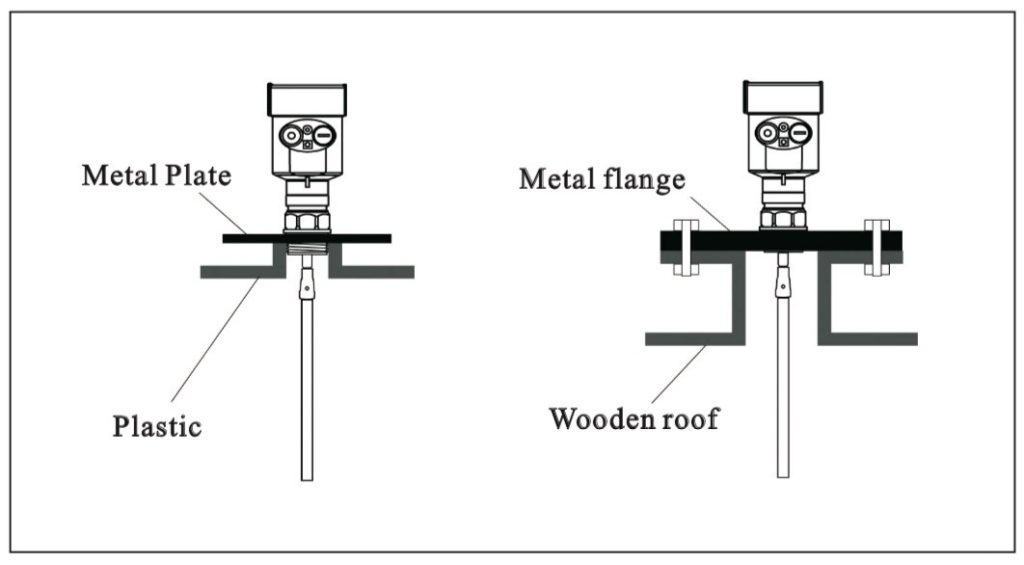

Guided Wave Radar Level Meter can be connected by threaded, thread length should not exceed 15mm, also can be installed on a short tube. In case the diameter of installation short tube is between 2″ and 6″, the height of installation short tube should ≤ 100mm( The shorter the thread and short tube, the more stable the measurement). In case the installation short tube is very long, it is best to cut it short, or using insulation bracket fixed cable type probe, avoiding probe in contact with the end of the short pipe to further to affect the measurement.

Please make sure cable or rod not in contact with internal obstacles within the measuring range. Therefore, please avoid facilities inside the tank as far as possible when installing, such as: human ladder, limit switches, heating devices, stand etc. Also note that the cable or rod may not intersect with the material during feeding.

Also note that when installing the meter : Highest level measurement cannot enter into the blind area: radar must keep a certain distance from tank wall. Please try to make the direction of cable or rod perpendicular to surface of measured medium. Meter installation in hazardous areas must comply with state regulations explosion hazardous installation area. Intrinsically safe instrument requires the use of shell with aluminum. Intrinsically safe instrument can be installed in occasions requiring explosion proof, the instrument must be connected to the earth.

Guided wave radar GWR installation of the cable and the rod radar level measuring solid powder or liquid. Usually, single rod radar level meter installation drawings, mainly used for liquid level measurement. Double rod radar level meter installation drawings, mainly for low dielectric constant liquid and solid lightweight powder measurements.If the measurement of corrosive media, the choice of rod or cable probe sets PTFE, PFA sleeve for Corrosive media measurement.

How to order guided wave radar?

The use and selection of the Solid level measurement instrument are more complicated. Because the tested medium is an irregular physical form. SenTec Radar Level Sensor for Solids is suitable for Dust solid level measurement. It is used in solid materials, strong dust, easy to crystallize, and condensation. Such as calcium carbonate powder level measurement. For Radar Level Sensor Price, please contact our sales engineer