Magnetostrictive liquid level transmitter is a kind of liquid level sensor. But it uses the principle of magnetostrictive operation internally. And combines modern electronic technology to measure the time value between pulse waves to achieve the purpose of accurately measuring the liquid level . The magnetostrictive liquid level meter works with waveguide pulses. During the work, the measured displacement is determined by measuring the time of the start pulse and the end pulse, so the measurement accuracy is high.

Magnetostricitive level transmitter working principle

Magnetostrictive Level Transmitters are level sensors for continuous level measurement. It is the best technology for monitoring and controlling liquid level interface.

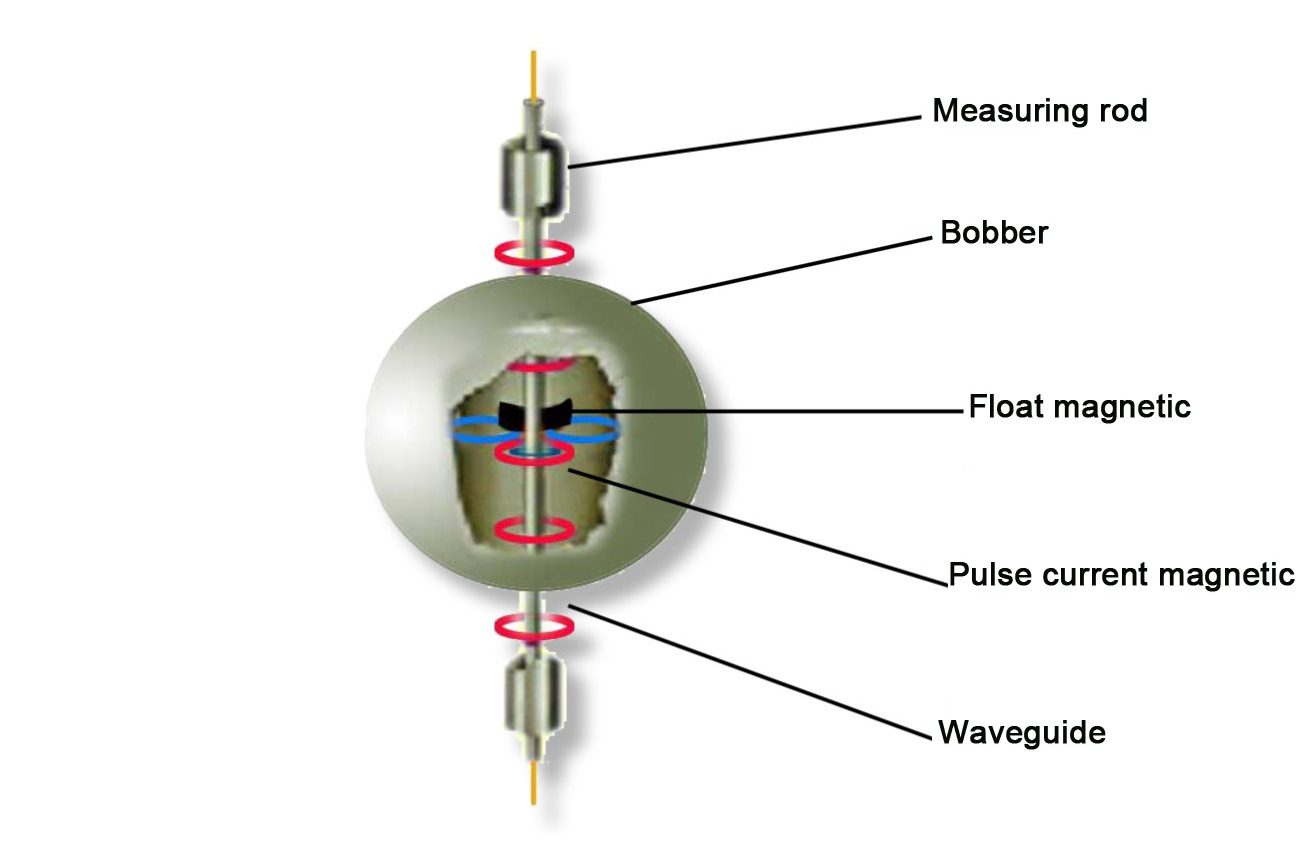

The structural part of the magnetostrictive liquid level sensor is composed of stainless steel tube (measuring rod), magnetostrictive wire (waveguide wire), movable float (with permanent magnet inside) and other parts, as shown in the figure.

When the sensor works, the circuit part will excite a pulse current on the waveguide wire, and when the current propagates along the waveguide wire, a pulsed electromagnetic field will be generated around the waveguide wire. There is a float outside the measuring rod of the sensor, which can move up and down along the measuring rod with the change of the liquid level. Inside the float there is a set of permanent magnetic rings. When the magnetic field of the pulse current meets the magnetic field of the magnetic ring generated by the float, the magnetic field around the float changes so that the waveguide wire made of magnetostrictive material generates a torsional wave pulse at the position of the float. The waveguide wire is returned and detected by the detection mechanism. By measuring the time difference between the pulse current and the torsional wave, the position of the float, that is, the position of the liquid surface, can be accurately

How does a magnetostrictive sensor work?

1.The device electronics generates a low energy current pulse at fixed intervals.

2.The electrical pulses create a magnetic field which travels down a specialized wire inside the sensor tube.

3.The interaction of the magnetic field around the wire and the magnetic float causes a torsional stress wave to be induced in the wire. This torsion propagates along the wire at a known velocity, from the position of the magnetic float and toward both ends of the wire.

4.A patented sensing element placed in the transmitter assembly converts the received mechanical torsion into an electrical return pulse.

5.The microprocessor-based electronics measures the elapsed time between the start and return pulses (Time of Flight). And converts it into a position measure-ment which is proportional to the level of the float.

Features of magnetostrictive level transmitter

Magnetostrictive Level Transmitters are divided into three types: flexible probe type, hard probe type, and outer float isolation detection. The watch body contains two main parts: the electronic part and the sensing part. The advantages of Magnetostrictive Level Transmitters are:

1. Strong reliability:

Because the magnetostrictive liquid level gauge adopts the principle of waveguide, there is no mechanical movable part. Therefore, there is no friction and no wear. The entire converter is enclosed in a stainless steel tube and is not in contact with the measurement medium. The sensor works reliably and has a long life.

2. High precision:

Because the magnetostrictive liquid level gauge works with waveguide pulses. In the work, the measured displacement is determined by measuring the time of the start pulse and the end pulse. Therefore, the measurement accuracy is high and the resolution is better than 0.01%FS. The accuracy achieved.

3. Good security:

Magnetostrictive liquid level gauge has high explosion-proof performance. Intrinsically safe explosion-proof and safe to use. Especially suitable for the measurement of chemical raw materials and flammable liquids There is no need to open the tank lid during the measurement. Avoid the unsafeness of manual measurement.

4. Easy to install and maintain:

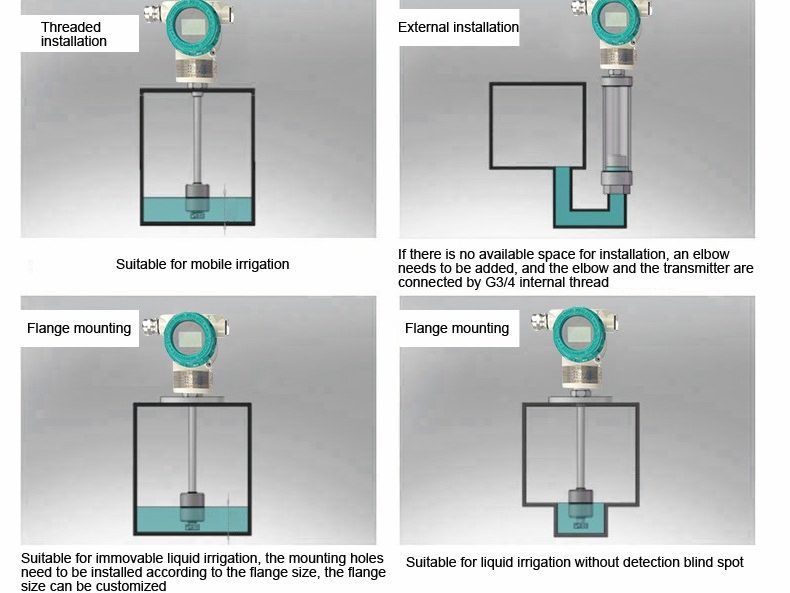

The magnetostrictive liquid level gauge is generally installed through the existing pipe opening on the top of the tank. It is especially suitable for the installation of underground storage tanks and storage tanks that have been put into operation. It can not affect normal production during the installation process.

5. Facilitate system automation:

The secondary instrument of the magnetostrictive liquid level gauge adopts the standard output signal. It is convenient for the computer to process the signal. It is easy to realize the network work and improve the automation degree of the entire measurement system.

Where is the magnetostrictive level gauge used?

Magnetostrictive liquid level transmitter application:

The high-tech magnetostrictive liquid level sensor is used in the liquid level measurement of various storage tanks. This kind of liquid level meter has the characteristics of high precision, strong environmental adaptability and convenient installation. Therefore, it is widely used in liquid level measurement fields such as petroleum and chemical industry, and gradually replaced other traditional sensors, becoming a high-quality product in liquid level measurement.

Typical applications and installations of magnetostrictive liquid level sensors:

▲ Measure the level of horizontal storage tanks: the magnetostrictive level sensor is mounted on the top

▲For production intermediate level control: the magnetostrictive level sensor is installed side-by-side

▲Application on vertical oil tank: Magnetostrictive liquid level transmitter adopts flexible cable top installation

▲ The magnetostrictive liquid level transmitter can also be used in conjunction with the magnetic flap liquid level gauge

▲Application and installation scheme of magnetostrictive liquid level transmitter, asphalt storage tank, etc

The advantages of the magnetostrictive level transmitter for oil tank level measurement

The advantages of the magnetostrictive level gauge for the measurement of the oil tank level are as follows:

1. Strong reliability: Because the magnetostrictive liquid level gauge adopts the waveguide principle and has no mechanical moving parts, it has no friction and no wear. The entire transducer is enclosed in a stainless steel tube, and is non-contact with the measuring medium. The sensor works reliably and has a long service life.

2. High precision: Since the magnetostrictive level gauge works with waveguide pulses, the measured displacement is determined by measuring the time of the initial pulse and the end pulse, so the measurement accuracy is high, and the resolution is better than 0.01%FS, which is It is an accuracy that is difficult to achieve with other sensors.

3. Good safety: The magnetostrictive liquid level gauge has high explosion-proof performance, intrinsically safe explosion-proof, safe to use, especially suitable for the measurement of chemical raw materials and flammable liquids. There is no need to open the tank cover during measurement, avoiding the insecurity of manual measurement.

4. The magnetostrictive liquid level gauge is easy to install and maintain: the magnetostrictive liquid level gauge is generally installed through the existing nozzle on the top of the tank, especially suitable for the installation of underground storage tanks and storage tanks that have been put into operation, and can be installed in The process does not affect normal production.

5. It is convenient for system automation work: The secondary instrument of the magnetostrictive liquid level gauge adopts standard output signal, which is convenient for the microcomputer to process the signal, and it is easy to realize the network work and improve the automation degree of the whole measurement system.

Magnetostrictive level gauge application

Magnetostrictive liquid level gauge is used for industrial measurement and control of liquid level in various liquid tanks such as petroleum, chemical raw material storage, industrial process, biochemical, pharmaceutical, food and beverage, tank farm management and gas station underground storage, dam water level, reservoir Water level monitoring and sewage treatment, etc.

How to order a magnetostrictive level transmitter ?

Magnetostrictive level transmitter Model Selection considerations:

1. The selection of the level gauge should be consistent with the environment of the media on the site. Including ambient temperature, pressure, vibration, shock, compatibility of structural materials and media, etc.

2. When the temperature of the measured medium is high (100 ~ 200), it is recommended to choose a probe with an outer float type and use a side flange installation. When the temperature is higher (200 ~ 300), it is recommended to choose a probe with a side-bundled type with an outer float, and install it with a side flange.

3. There are measurement dead zones at the upper and lower ends of the measuring rod of the magnetostrictive level gauge, which should be considered when selecting the range.

4. The size of the stainless steel magnetic float commonly used for level gauges is Ф45 × 56 × Ф15, and flange connection of DN50 or above is required. For the liquid level gauge with thread connection, users need to install flange or bracket.

The price of a magnetostrictive level transmitter is determined based on the measurement conditions. SenTec is a manufacturer of magnetostrictive level gauges. We offer magnetostrictive level gauges at the right price.

※Note: The corresponding management system software can be prepared according to the requirements of use, which can realize the display of the liquid level height, temperature, volume, mass, density and other parameters of each medium, and can automatically generate reports and print, network distribution, remote accurate monitoring and other advanced advanced technology management functions.

For specific Magnetostrictive level transmitter price, please contact our sales engineer.