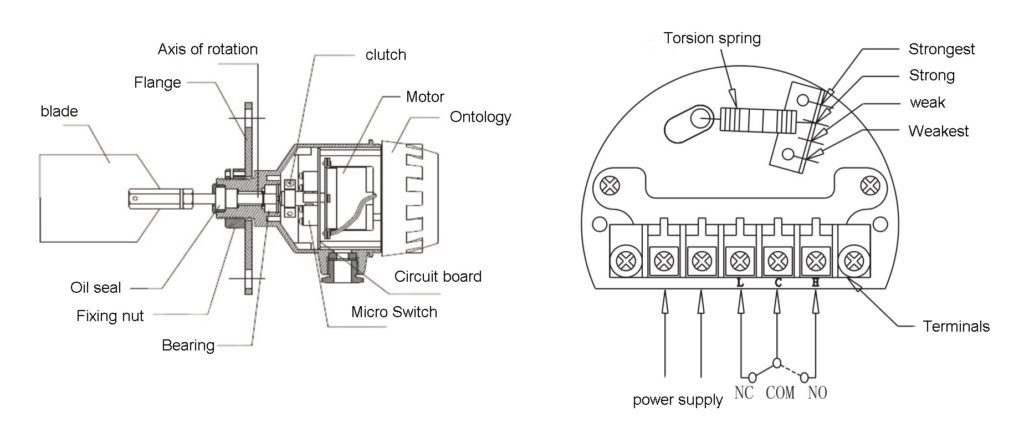

The rotary material point level switch is the latest professional manufacture. It uses a micro motor as the driving device, and the transmission shaft is connected with the clutch. When the material is not in contact with the material, the motor runs normally. When the blade contacts the material, the motor stops rotating and the detection device outputs a Contact signal, and cut off the power supply at the same time to stop the rotation.

Rotary paddle level switch working principle

The working principle of the anti-rotation controller is: after the AC micro-motor is decelerated, the monitoring blade is driven to rotate at a slow speed. When the material level rises and the rotation of the blade is blocked, the detection mechanism will generate a rotational displacement around the main shaft. This displacement first makes a micro switch act to send out a material signal. Then another micro switch acts to cut off the power of the micro motor to stop the rotation. This state will remain as long as the material level in the bin remains unchanged.

What are the rotary paddle level switch advantages ?

1. Using contact measurement, the results are real, accurate and reliable; it can be installed horizontally, inclined and vertically, and it is easy to install and use.

2. Anti-interference, ready to use after installation: Because there are no complex electronic components and their amplifying circuit parts inside, they are not subject to any electromagnetic wave interference, and can be used for a long time without any debugging and maintenance after installation.

3. Super anti-shake performance design: no false signal even when the material is flowing.

4. Material level display function: The long-life high-brightness indicator light is adopted, and the material level display is intuitive and convenient.

5. Double protection function: The overload protection function prevents the blades from being damaged by excessive external force and damages the motor; the automatic protection function makes the material level indicator stop working when the material in the silo is blocked by the rotation of the blades, which protects the motor and effectively prolongs its service life.

6. Excellent measurement reproducibility and adaptability to environmental conditions: that is, it is not affected by changes in material particle size, shape, specific gravity, medium, wall scale, adhesion, temperature, humidity, dust concentration, etc.

7. Super dust-proof sealing performance, even if the pressure is 1MPa, dust cannot enter.

8. The design of shock resistance and anti-loosening structure can effectively prevent the parts from loosening and slipping; the high-quality stainless steel material is used to make it have excellent corrosion resistance and wear resistance.

9. Low price and excellent cost performance.

Material level switch VS Material level meter

The resistance-rotating material level meter, that is, the resistance-rotating material level controller, is referred to as “material level device”, “material level meter”, “material level switch”, “material level switch”, “material level meter”, “material level meter”. It is mainly used for automatic detection and control of the limit material level of various materials (such as powder, granule or block) in the silo. Different types of material level sensors can meet the requirements of different working conditions. Grain, flour, building materials, cement, electric power, coal, chemical industry, foundry, rubber, environmental protection dust removal and other industries have a wide range of applications in the process of material transportation and control.

SenTec have more solutions for silo powder, granule or block detection sensor. such as the RF admittance level swtich, vibration tuning fork level switch sensor etc.

Rotary material switch application

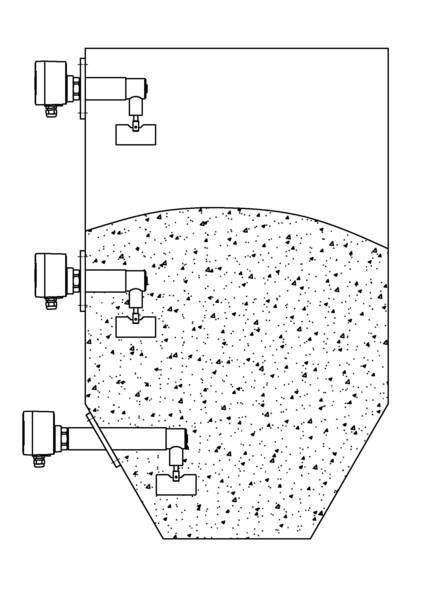

Rotary level gauges are widely used in modern industrial production processes and warehousing sectors.

It can monitor and control the upper and lower limits of the powder and granular materials in the open container, with: advanced technology,

Reasonable structure, reliable performance, easy installation, high cost performance, is the first choice to replace imported products.

In order to meet the needs of different specific gravity of various materials, the resistance rotary material level meter is designed with a five-speed device to adjust the detection sensitivity.

The anti-rotation material level gauge adopts an overload protection device, which effectively avoids the damage to the motor and reducer caused by improper use or abnormal external force.

The main exposed parts of the resistance rotary material level gauge are made of stainless steel and aluminum alloy. It can be used in harsh environments such as high dust and open air.

How to install a rotary paddle level switch sensor?

Rotary level paddle switch sensor Installation Precautions:

During the use of the anti-rotation level switch, in order to achieve a safe and reliable effect, the following points should be paid attention to when installing the anti-rotation level switch:

1. Before installation, it is first necessary to confirm whether the type of the rotary material level switch meets the environmental requirements of the site, such as: pressure, temperature, medium, etc., to ensure that the rotary material level switch can be used normally after installation.

2. Before installation, confirm whether the power supply voltage is consistent with the voltage marked on the nameplate.

3. Select the best blade shape according to the density of the measured medium.

4. In order to ensure the safety of life and avoid damage to the rotary material level switch, wiring is required in the case of power failure.

5. When installing horizontally, the switch can be installed at an angle of 15-20 degrees horizontally to avoid the impact of the feed and try to avoid the feed port.

Rotary material switch installation attentions requirements:

1. The installation of the anti-rotation material level gauge should make the position of the blade avoid the lower part of the feeding port and the dead material area of the silo. In order to prevent the impact of the material in use, a protection should be installed above the detection blade plate.

2. If the extension shaft is used for vertical installation, a protective sleeve should be installed or the position of the blade and the flexible shaft will not be directly hit by the material. When measuring multiple positions, the distance should be properly opened to avoid the mutual winding of the flexible shafts.

3. In order to avoid the infiltration of rainwater in the outdoor environment, the cable outlet should be vertically downward and the upper cover should be tightened when installing on the side. If there are conditions for vertical installation, you can consider installing a rain cover.

※Note: As one of the earlier level measurement manufacturer, SenTec provide A wide variety Level switch Sensor for tank level measurement solutions.

For specific rotary paddle Level switch Sensor price, please contact our sales engineer.