Ultrasonic level gauge also called, Ultrasonic fuel tank level sensor, non-contact fuel meter, is an electronic level transmitter, measuring continuous liquid level, fluid level, or oil level.

Ultrasonic Liquid Level Sensor can realize non-contact liquid level measurement. Continuous online monitoring of water level and sludge interface position.

Working principle of ultrasonic level gauge

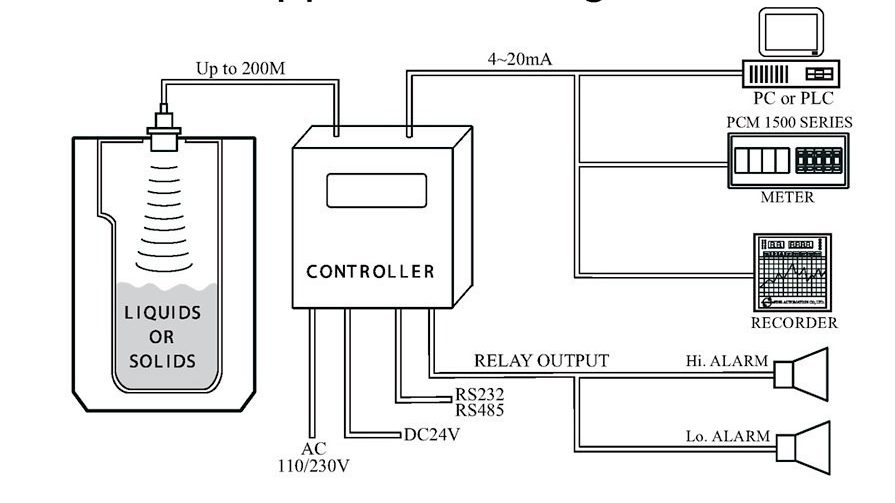

The principle of the split type ultrasonic level gauge is to measure the time required for an ultrasonic pulse to be sent out to the whole process of returning. It is used for liquid level and volume measurement in tanks, pools, and reservoirs, and can also be used for open channel flow measurement. Ultrasonic fuel tank level sensor, also called non-contact fuel meter, is an electronic level transmitter, measuring continuous liquid level, fluid level, or oil level.

What the solutions can a ultrasonic level sensor for tank level measurement?

SenTec ultrasonic fuel level sensor models provide continuous, non-contact measurement (like radar), making them ideal for measuring fluids found in machine tools, like oil or hydraulic fluid, that cannot be tainted by the introduction of foreign materials.

Our ultrasonic fuel level measurement modules can be programmed to account, for oscillations and turbulence, that could otherwise lead to incorrect readings.

SenTec provide Advanced Tank Level Measurements, such as, Tank Level Measurements,Chemical Level Measurement, Tank Level Display,Tank Level Alarms, Tank Level Control etc.

ultrasonic level gauge application

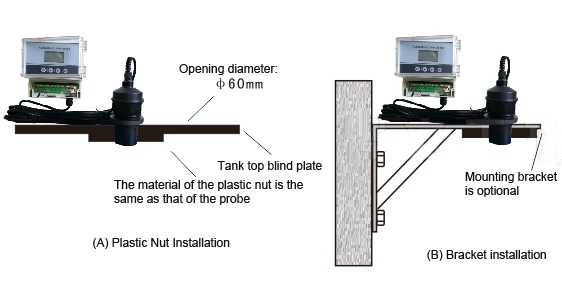

Ultrasonic Liquid Level Sensor Installation principles

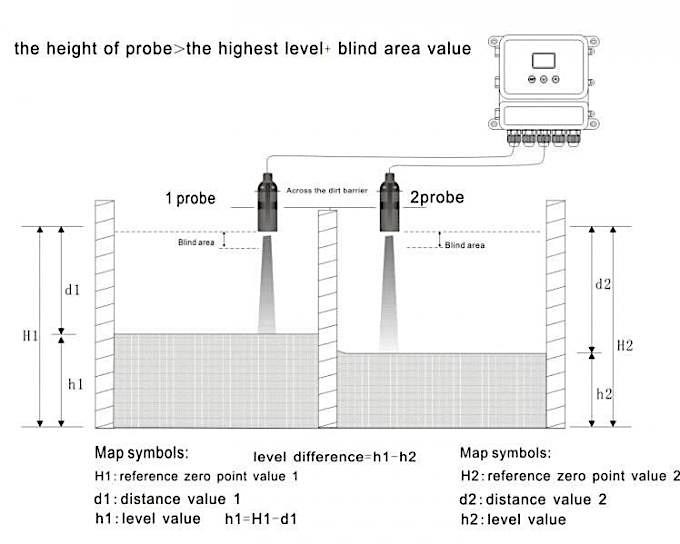

1) The distance from the transmitter surface of the sensor to the lowest liquid level should be less than the range of the purchased instrument.

2) The distance from the transmitter surface of the sensor to the highest liquid level should be greater than the blind area of the purchased instrument.

3) The emitting surface of the sensor should be kept parallel to the liquid surface.

4) The installation position of the sensor should try to avoid the position where the liquid level fluctuates violently, such as the inlet and outlet directly below.

5) If the tank wall or tank wall is not smooth, the instrument should be separated from the tank wall or tank wall by more than 0.3m.

6) If the distance from the sensor emitting surface to the highest liquid level is less than the blind area of the purchased instrument, an extension pipe needs to be installed. The extension pipe has a diameter greater than 120mm and a length of 0.35m to 0.50m. It is installed vertically and the inner wall is smooth. greater than the inner diameter of the extension tube. Or you can put the pipe directly to the bottom of the tank, the diameter of the pipe is greater than 80mm, and the hole at the bottom of the pipe is convenient for the inflow of liquid.

SenTec has been producing ultrasonic sensors for more than 20 years and developing technologies and products for ultrasonic applications. Ultrasonic series products include ultrasonic level meter (ultrasonic level meter, ultrasonic level meter), ultrasonic flowmeter, ultrasonic interface meter, ultrasonic water depth meter, tank body mounted liquid level meter, remote sonic well depth meter, ultrasonic (liquid, slurry) Body) concentration meter, ultrasonic tide gauge and other physical quantity sensors and instrument systems. SenTec Is a professional manufacturer of industrial inspection ultrasonic technology. SenTec offers more than20 ultrasonic level detectors products, like ultrasonic level transducers, ultrasonic level indicators.

For specific ultrasonic level sensor price, please contact our sales engineer.