Pressure transmitter is a device that converts pressure into pneumatic signal or electric signal for control and remote transmission.

It can convert the gas, liquid and other physical pressure parameters felt by the load cell sensor into a standard electrical signal (such as 4-20mADC, etc.). Use secondary instruments such as indicator alarms, recorders, and regulators for measurement, indication, and process adjustment.

Industrial Pressure Transmitters are precision-engineered to fit most industrial pressure measurement applications. Sino-Instrument offers industrial pressure transmitters with the display, 4-20ma output.

The industrial pressure transmitter can work as a natural gas pressure transducer, water pressure transmitter.

Explosion Proof Pressure transmitter refers to a pressure sensor with explosion-proof or intrinsically safe housing. Suitable for hazardous and explosive areas.

What the Explosion proof pressure transmitter working principle ?

The explosion-proof pressure transmitter consists of an integrated intelligent sensor and peripheral circuits.

The sensor part is composed of a pressure sensor, a signal modulation circuit, a dedicated digital processing chip, a temperature sensor, and data memory, and the peripheral electronic circuit part is composed of an LCD display, function keys, and an EMC circuit.

The pressure signal is converted into an electrical signal by the pressure sensor. And the electrical signal is modulated. And sent to a dedicated digital processing chip for data processing. And then converted into a 4~20 mA output signal corresponding to the pressure signal.

Where are pressure transmitter used for?

Pressure transmitters are widely used. Typical examples are constant pressure water supply, pipeline monitoring, hydraulic systems, automated testing, etc. Used for air pressure, hydraulic, oil pressure testing.

What common types of pressure can you measured by a explosion proof pressure transmitter?

We use three common types in the industry.

- The first is “gauge pressure”. Measured with reference to atmospheric pressure (typically 14.7 PSI). When above atmospheric pressure, you will display a “positive” pressure; when below atmospheric pressure, you will display a “negative” pressure.

- The next is “absolute pressure“. In short, this is the pressure relative to an absolute vacuum measurement. The absolute pressure of the full vacuum is zero PSIa and it increases from there. This type of sensor can be used if it is necessary to read pressures below atmospheric pressure.

- The last type that is usually monitored in the industry is “pressure differential”. It sounds like this, the difference between two pressures, a measured pressure and a reference pressure.

Where you can read the value of the explosion proof pressure transmitter?

The pressure transmittter can output general analog signals. Compatible with various data acquisition equipment. Such as digital display meter, recorder, PLC, DCS. RS485 communication, which can be connected to a computer.

How to choose the right industrial pressure transmitter?

1. First, you need to determine the scope of your stress test. In general, the range is selected according to the actual measurement pressure as 80% of the measurement range.

2. Determine the output signal, voltage output or current output or direct digital signal?

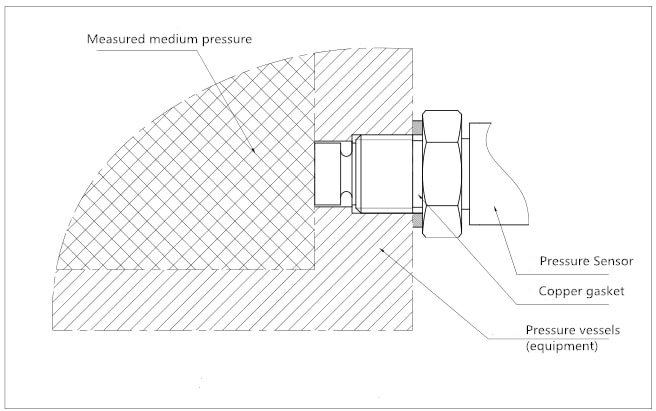

3. Process connection.

4. It is also necessary to determine whether corrosion resistance is required.

5. If it is to measure sewage or there are many impurities in it, it is better to choose a flush membrane.