Thermocouple sensors are the most common contact temperature measurement devices used in industry. This is because the thermocouple has the characteristics of stable performance, large temperature measurement range, long-distance signal transmission, simple structure and convenient use. Thermocouples can directly convert thermal energy into electrical signals and output a DC voltage signal, making it easy to display, record and transmit.

THERMOCOUPLE TEMPERATURE SENSOR MEASUREMENT PRINCIPLE

Two conductors of different compositions (called thermocouple wires or thermodes) are connected to form a loop at both ends. When the temperature of the two junctions is different, an electromotive force will be generated in the loop. This phenomenon is called the thermoelectric effect. This electromotive force is called thermoelectric potential. Thermocouples use this principle to measure temperature. One end that is directly used to measure the temperature of the medium is called the working end (also called the measuring end), and the other end is called the cold end (also called the compensation end); the cold end and the display The meter or supporting meter is connected, and the display meter will indicate the thermoelectric potential generated by the thermocouple.

What are the advantages of thermocouple sensor ?

* Simple assembly and easy replacement

* Compression spring type temperature sensing element, good shock resistance

*Large measurement range (-200℃~1300℃, in special cases -270℃~2800℃)

*High mechanical strength, good pressure resistance

* High temperature resistance up to 2800 degrees

What are common thermocouples types ?

Commonly used thermocouples can be divided into two categories: standard thermocouples and non-standard thermocouples. The standard thermocouple referred to refers to the thermocouple whose relationship between thermoelectric potential and temperature, allowable error, and a unified standard graduation table is specified in the national standard. Non-standardized thermocouples are not as good as standardized thermocouples in terms of use range or order of magnitude, and generally do not have a unified indexing table, which is mainly used for measurement in some special occasions. Seven standardized thermocouples S, B, E, K, R, J, T:

Commonly used thermocouple model Thermocouple graduation number Thermoelectrode material Operating temperature (℃)

S Platinum-rhodium alloy (10 % rhodium content) Pure platinum 0-1600

R Platinum-rhodium alloy (13 % rhodium content) Pure platinum 0-1600

B Platinum-rhodium alloy (rhodium content 30%) platinum-rhodium alloy (rhodium content 6%) 0-1800

K NiCrNiSi 0-1300

T Pure copper Copper nickel 0-350

J Iron Copper Nickel 0-+500

N NiCrSi NiSi 0-+800

E Nickel Chromium Copper Nickel 0-600

Types of thermocouples: assembly thermocouples, armored thermocouples, end face thermocouples, compression spring fixed thermocouples, high temperature thermocouples, platinum rhodium thermocouples, anticorrosion thermocouples, wear-resistant thermocouples, high voltage thermocouples, special thermocouples, Handheld thermocouples, miniature thermocouples, precious metal thermocouples, fast thermocouples, tungsten-rhenium thermocouples, single-core armored thermocouples, etc.

How does temperature compensation for the cold junction of a thermocouple sensor work?

Since the materials of thermocouples are generally more expensive (especially when precious metals are used), and the distance between the temperature measurement point and the instrument is very long, in order to save thermocouple materials and reduce costs, compensation wires are usually used to connect the cold end (free) of the thermocouple. terminal) extends to the control room where the temperature is relatively stable, and connects to the instrument terminal. It must be pointed out that the function of the thermocouple compensation wire is only to extend the hot electrode, so that the cold end of the thermocouple is moved to the instrument terminal of the control room. Therefore, other correction methods need to be used to compensate the influence on the temperature measurement when the cold junction temperature t0≠0℃. When using the thermocouple compensation wire, it is necessary to pay attention to the matching model, the polarity cannot be wrongly connected, and the temperature of the compensation wire and the thermocouple connection end cannot exceed 100 ℃.

THERMOCOUPLE TEMPERATURE SENSOR APPLICATION

A thermocouple is a temperature sensing element and an instrument. It directly measures the temperature, and converts the temperature signal into a thermoelectromotive force signal, and converts it into the temperature of the measured medium through an electrical instrument (secondary instrument).

Types of thermocouples: assembly thermocouples, armored thermocouples, end face thermocouples, compression spring fixed thermocouples, high temperature thermocouples, platinum rhodium thermocouples, anticorrosion thermocouples, wear-resistant thermocouples, high voltage thermocouples, special thermocouples, Handheld thermocouples, miniature thermocouples, precious metal thermocouples, fast thermocouples, tungsten-rhenium thermocouples, single-core armored thermocouples, etc.

The selection of thermocouples should be comprehensively considered according to the temperature range of use, the required accuracy, the use atmosphere, the performance of the object to be measured, the response time and economic benefits.

1. Selection of measurement accuracy and temperature measurement range

When the operating temperature is 1300~1800℃, and the accuracy is required to be relatively high, the B-type thermocouple is generally used; the accuracy is not high, and the atmosphere allows the use of tungsten-rhenium thermocouples. Above 1800℃, tungsten-rhenium thermocouples are generally used; 1000~1300°C requires high precision and relatively high temperature. S-type thermocouple and N-type thermocouple are available; K-type thermocouple and N-type thermocouple are generally used below 1000°C, and E-type thermocouple is generally used below 400°C; And negative temperature measurement generally uses T-type thermocouples, which are stable and accurate at low temperatures.

2. The choice of atmosphere

S-type, B-type and K-type thermocouples are suitable for use in strong oxidizing and weak reducing atmospheres. J-type and T-type thermocouples are suitable for weak oxidizing and reducing atmospheres. If a protective tube with better air tightness is used, the Atmosphere requirements are less stringent.

3. Choice of durability and thermal responsiveness

Thermocouples with large wire diameters have good durability, but their response is slower. For thermocouples with large heat capacity, the response is slow. When measuring temperatures with large gradients, the temperature control is poor in the case of temperature control. If the response time is fast and the durability is required, it is more appropriate to choose the armored pair.

4. The nature and state of the measurement object to the selection of the thermocouple

The temperature measurement of moving objects, vibrating objects, and high-pressure containers requires high mechanical strength. The atmosphere with chemical pollution requires a protective tube. In the case of electrical interference, the insulation is required to be relatively high.

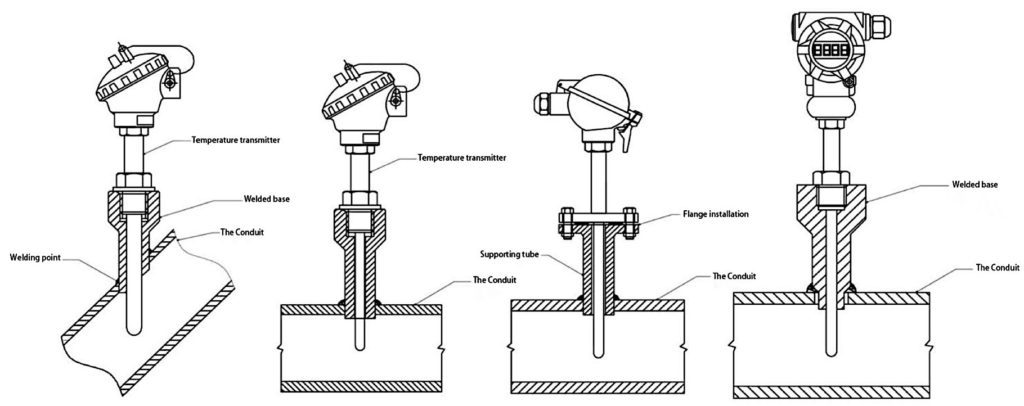

Selection process: model – graduation number – explosion-proof grade – accuracy grade – installation and fixed form – protection tube material – length or insertion depth