Turbine flow meter are widely used in flow measurement: petroleum, organic liquids, inorganic liquids, liquefied gas, natural gas, coal gas and cryogenic fluids. Turbine flowmeter signals can be divided into pulse signals or current signals (4-20mA). It is suitable for use with secondary display, PLC, DCS and other computer control systems.

Why turbine flowmeter is Pulse Output Flow Meter ?

A pulse flowmeter is a type of flowmeter that can measure flow in the form of pulses. The most common one is called a turbine flowmeter.

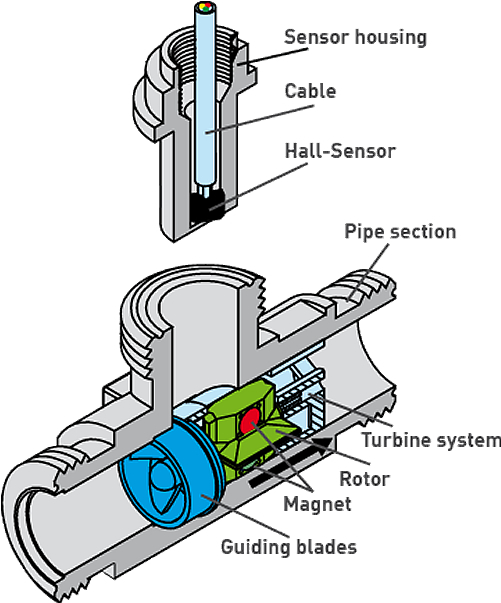

In a turbine flowmeter, a turbine is positioned at the center of the pipeline and supported by bearings at both ends. As the fluid passes through the pipeline, it strikes the blades of the turbine, generating a driving torque that allows the turbine to overcome friction and fluid resistance, resulting in rotation.

Within a specific flow range and for a given fluid viscosity, the rotational speed of the turbine is directly proportional to the velocity of the fluid flow. This means that by measuring the rotational speed of the turbine, we can determine the velocity of the fluid. As a result, we can calculate the flow rate of the fluid passing through the pipeline.

How does a turbine type flow meter work ?

The turbine flow meter has a turbine. It needs to be installed in the fluid pipeline when in use, and both ends are supported by bearings.

When the fluid passes through the turbine. The fluid hits the turbine blades. Drive the rotation of the turbine blades. The flow rate is measured indirectly through the angular velocity of the turbine blades. The method used is that the angular velocity of the blades is proportional to the fluid velocity.

Liquid Turbine Flow Meter Working Principle

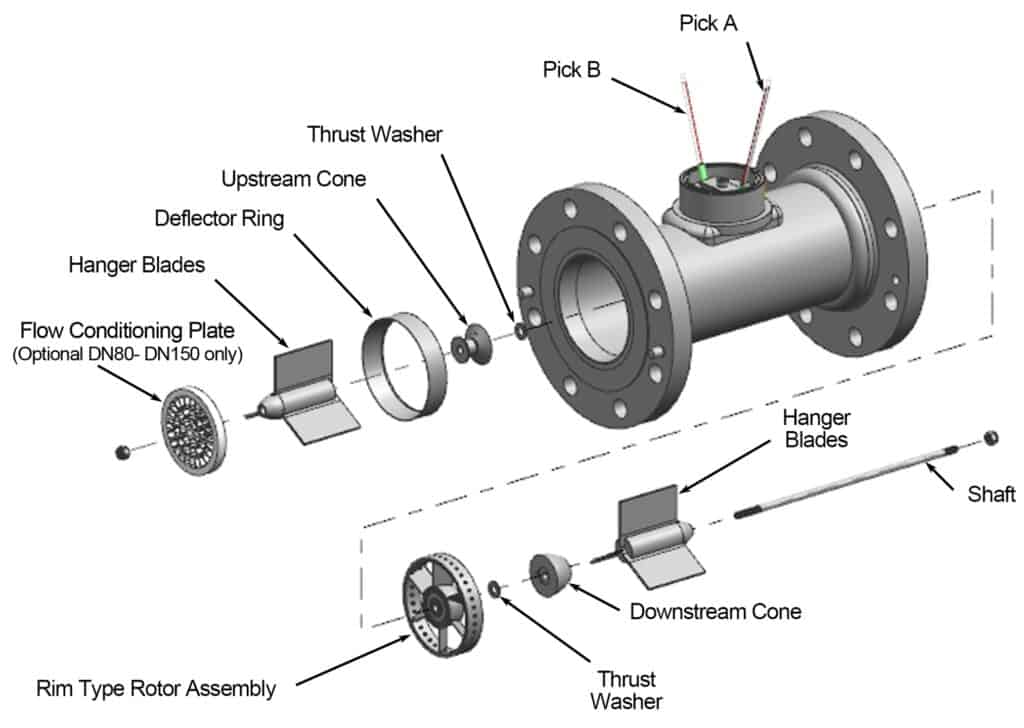

The working principle of the turbine flowmeter: the fluid flows through the sensor housing. Since the blades of the impeller have a certain angle with the flow direction, the impetus of the fluid makes the blades have a rotating torque. After overcoming the friction torque and fluid resistance, the blades rotate, and the speed is stable after the torque is balanced. , Under certain conditions, the rotational speed is proportional to the flow rate. Since the blade is magnetically permeable, it is in the magnetic field of the signal detector (composed of a permanent magnet and a coil). The rotating blade cuts the magnetic field lines, periodically changing the coil’s Magnetic flux, so that the two ends of the coil induce an electrical pulse signal, which is amplified and shaped by the amplifier to form a continuous rectangular pulse wave with a certain amplitude, which can be transmitted to the display instrument to display the instantaneous flow and cumulative volume of the fluid. Within a certain flow range, the pulse frequency F is proportional to the instantaneous flow rate Q of the fluid flowing through the sensor, and the flow equation is: Q=3600×f/k

In the formula:

F——Pulse frequency [Hz];

k——The meter factor of the sensor [1/m], given by the checklist. If the unit is [1/L] Q=3.6×f/k

Q——Instantaneous flow of fluid (under working condition) [m3/h];

3600 – conversion factor.

The instrument coefficient of each sensor is filled in the verification certificate by the manufacturer, and the k value is set in the matching display instrument, which can display the instantaneous flow and cumulative total.

Gas turbine flow meter working principle

The gas turbine flowmeter uses a turbine for measurement. It first converts the flow rate into the rotational speed of the turbine, and then converts the rotational speed into an electrical signal proportional to the flow rate. Gas turbine flowmeter is used to detect instantaneous flow and total integrated flow. Its output signal is frequency, which is easy to digitize.

The induction coil and the permanent magnet are fixed on the housing together. When the ferromagnetic turbine blade passes the magnet, the reluctance of the magnetic circuit changes, thereby generating an induction signal.

The signal is amplified and reshaped by the amplifier and sent to the counter or frequency meter. The total accumulated flow is displayed. At the same time, the pulse frequency undergoes frequency-voltage conversion to indicate instantaneous flow.

The speed of the impeller is proportional to the flow, and the number of revolutions of the impeller is proportional to the total amount of flow. The output of the turbine flowmeter is a frequency modulated signal. It not only improves the anti-interference of the detection circuit, but also simplifies the flow detection system.

The gas turbine flowmeter has a turndown ratio of up to 10:1, and the accuracy is within ±0.2%. The time constant of the turbine flowmeter with small inertia and small size can reach 0.01 second.

What are the advantages of turbine flow meter?

Turbine flowmeter has the advantages of high precision, good repeatability, no zero drift, and high turndown ratio. Turbine flowmeters have high-quality bearings, specially designed guide vanes, which greatly reduce wear, are insensitive to peaks, and give reliable measured variables even under harsh conditions.

types of turbine sensor connection structure

Turbine Sensor Structure Type usually have following types:

Flange connection type Liquid Turbine flow sensor

Thread connection type Liquid Turbine flow sensor

Clamping band connection type Liquid Turbine flow sensor

Flange connection type Gas Turbine Flow Sensor

Types of turbine flow meter

Generally speaking, according to the measuring medium, we can divide the turbine flowmeter into liquid turbine flowmeter and gas flowmeter.

According to the function of the turbine flowmeter, we can divide the turbine flowmeter into a basic turbine flowmeter, Electronic turbine flow sensor and an intelligent turbine flowmeter.

1.Basic turbine flowmeter

The turbine sensor itself does not have the on-site display function, and only transmits the flow signal remotely.

The flow signal can be divided into pulse signal or current signal.

Low price, high integration, small size, especially suitable for use with secondary display, PLC, DCS and other computer control systems.

2.Electronic turbine flow sensor

Electronic turbine flow sensor is an intelligent flow switch, is an exquisite type of flow sensor. It has the advantages of small

volume, simple setting and so on. The built-in intelligent circuit can set the alarm value of the upper and lower limits of the flow arbitrarily, can monitor the real-time flow status remotely, set the full parameters on the spot arbitrarily, and the turbine measurement medium can be processed by the flow through the sensor functional circuit after arbitrary programming.

3.Intelligent turbine flowmeter

Intelligent turbine flowmeter, a display integrated instrument developed by combining turbine flow sensor and advanced ultra-low power single-chip microcomputer technology.

It has the advantages of compact structure, high reliability, resistance to external power supply interference, lightning protection, and low cost.

Three-point correction of instrument coefficients can be carried out on site, and nonlinearity of instrument coefficients can be intelligently compensated.

Simultaneously display instantaneous flow, cumulative flow, temperature, pressure and other measurement parameters.

It has real-time data storage function and explosion-proof function.

Especially suitable for use with PLC, DCS and other computer control systems.

Turbine Flow Meter Applications

Turbine flowmeter is a kind of speed meter, which has the advantages of high precision, good repeatability, simple structure, few moving parts, high pressure resistance, wide measurement range, small size, light weight, small pressure loss, convenient maintenance, etc. It is used for Volumetric flow and total volume measurement of low-viscosity gases in closed pipes. Turbine flowmeters are widely used in the following measurement objects: petroleum, organic liquids, inorganic liquids, liquefied gas, natural gas, coal gas and cryogenic fluids. Transshipment and gathering stations for liquefied petroleum gas, refined oil and light crude oil abroad. Turbine flowmeters are second only to orifice flowmeters in natural gas measuring instruments in Europe and the United States. In the Netherlands alone, more than 2,600 gas turbine flowmeters of various sizes and pressures from 0.8MPa to 6.5MPa have been used in natural gas pipelines. Has become an excellent natural gas flowmeter.

Turbine Flow Meter Installation Attentions

1. The instrument installation adopts flange connection, threaded connection and clip-on type;

2. When installing, the liquid flow direction should be consistent with the direction of the arrow indicating the flow direction on the sensor shell, and the upstream straight pipe section should be ≥6DS, and the downstream straight pipe section should be ≥5DS (DS is the measured inner diameter of the pipe under test).

3. The sensor should be kept away from the external magnetic field. If it cannot be avoided, necessary measures should be taken;

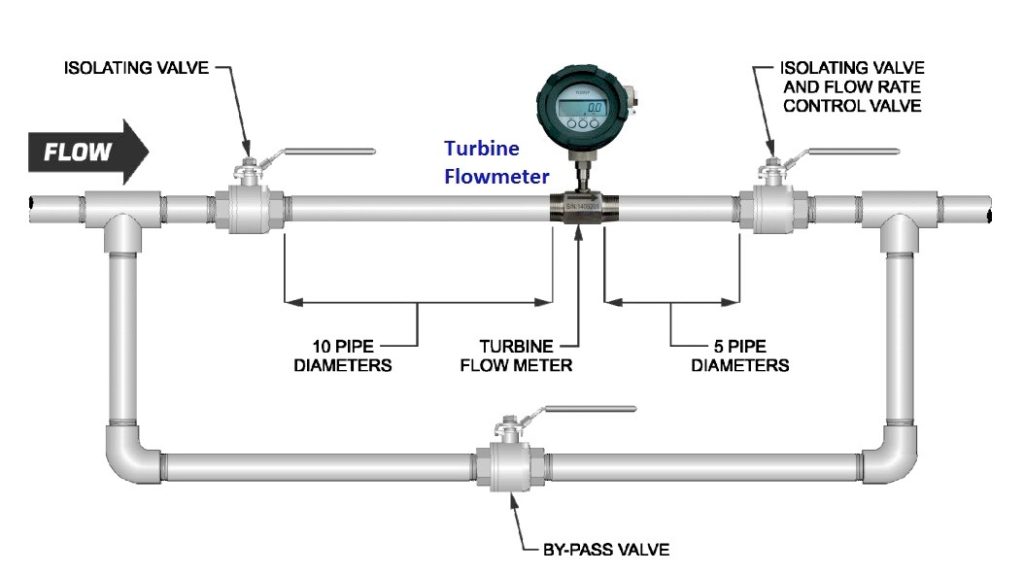

4. In order not to affect the normal transportation of liquid during maintenance, bypass pipes should be installed outside the straight pipe sections at both ends of the sensor;

5. When the sensor is installed in the open air, please do a good job of waterproofing the amplifier plug;

6. For the wiring between the sensor and the display instrument, the wiring method should be selected according to the power supply of the amplifier. For details, please refer to the relevant “Instruction Manual”

How to choose a suitable turbine flowmeter ?

The correct selection of the turbine flowmeter can ensure the better use of the turbine flowmeter. What type of turbine flowmeter should be selected according to the physical and chemical properties of the fluid to be measured? Make the diameter, flow range, lining material, electrode material and output current of the turbine flowmeter adapt to the properties of the fluid to be measured. and flow measurement requirements.

1. Precise functional inspection

Accuracy class and function Select the instrument accuracy class according to the measurement requirements and application occasions.

2. Measurable medium

Measuring medium flow rate, instrument range and caliber When measuring general medium, the full-scale flow rate of the turbine flowmeter can be selected within the range of 0.5-12m/s of the measured medium flow rate, and the range is relatively wide. The specification (diameter) of the selected instrument is not necessarily the same as that of the process pipeline. It should be determined according to whether the measurement flow range is within the range of the flow rate, that is, when the flow rate of the pipeline is too low to meet the requirements of the flow meter or the measurement accuracy cannot be guaranteed at this flow rate, It is necessary to reduce the diameter of the instrument, so that the flow rate in the high pipe can be obtained to obtain satisfactory measurement results.