An ultrasonic heat meter is an instrument that calculates heat.

The heat meter is to install a pair of temperature sensors on the ascending pipe and descending pipe passing the heat carrier fluid respectively, and the flow meter is installed on the fluid inlet or return pipe (the location of the flow meter is different, the final measurement results are also different), the flow rate The meter sends out a pulse signal proportional to the flow rate, a pair of temperature sensors gives an analog signal indicating the temperature, and the integrator collects the signals from the flow rate and temperature sensors, and uses the calculation formula to calculate the heat obtained by the heat exchange system.

What is the difference between the ultrasonic flowmeter and ultrasonic heat meter ?

Ultrasonic heat meter also called ultrasonic calorimeter. To simplify, you can understand the difference by following form:

Ultrasonic Flow meter = Converter + transducer

Ultrasonic Heat meter = Converter + transducer + Temperature transducer

Ultrasonic Heat Meter Applications

The external clamp or pipe segment ultrasonic heat meter is based on the principle of “velocity difference method” to measure the liquid flow in the circular tube. It adopts advanced multi-pulse technology, signal digital processing technology and error correction technology, which makes the flow meter more suitable for the environment of the industrial site, and the measurement is more convenient, economical and accurate. The products have reached the advanced level at home and abroad, and can be widely used in petroleum, chemical, metallurgy, electric power, water supply and drainage and other fields.

Ultrasonic Heat Meter Installation

The measurement line accuracy of the time difference ultrasonic flowmeter is higher than 1.0%. Due to the diversity of the industrial site, especially the surrounding environment of the pipeline, how to install and debug the ultrasonic calorimeter according to the specific environment? How to Choose ultrasonic heat sensor installation points ?

Proper installation point is a key for transducer installation. Following factors must be considered: Full filled pipeline, shaking, steady flow, scaling, temperature, pressure, EMI, instrument well.

>> Full filled pipeline

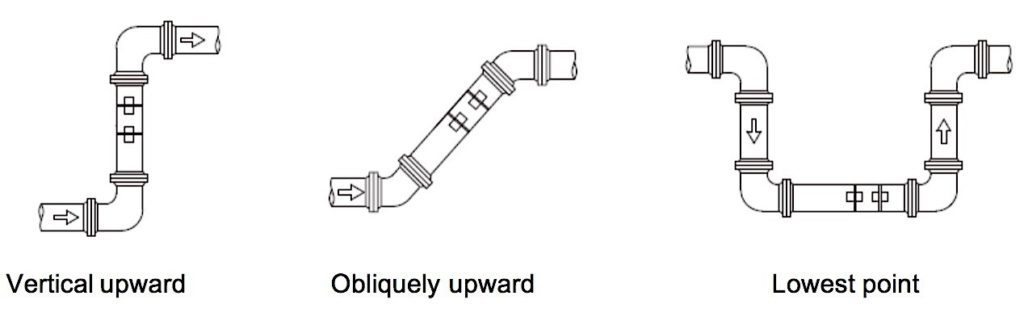

Following situations can be full filled of liquid:

>> Shaking

There cannot be obvious shaking on the installation point, otherwise it needs to be tightened.

>>Steady flow

Steady flow is helpful for ensuring measurement accuracy.

Standard requests for steady flow are:

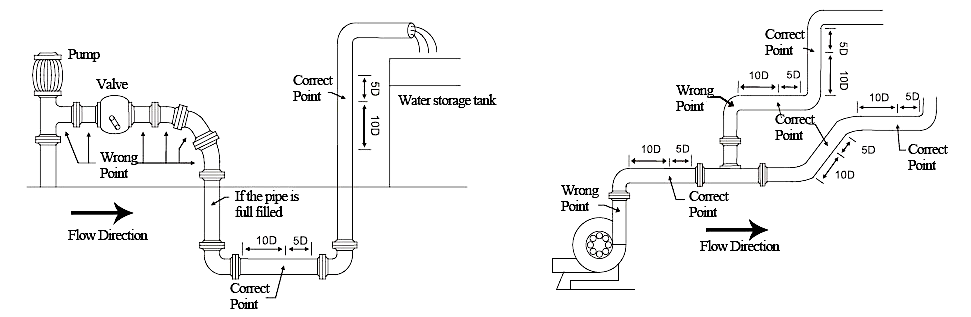

1. The pipe should be far away from pump outlet and half-open valve.

10D to upstream and 50D to downstream. (D means outer diameter)

2. 30D to pump outlet and half-open valve.

>> Scaling

The inside scaling would have bad effect on ultrasonic signal transmission, and would decrease the inner diameter as well. As a result, the measurement accuracy can not be guaranteed. Please try to avoid choosing the installation point with inside scaling.

>>Temperature

The liquid temperature on installation point should be in the working range of transducers. Please try to choose the point with lower temperature. Avoid to choose points like the outlet of boiler water and heat exchanger. Return water pipe would be better.

Temperature range of standard clamp on and insertion transducers: -30 ~ 90℃

Temperature range of high temperature clamp on and insertion transducers: -30 ~ 160℃

>>Pressure

The maximum pressure for standard insertion and inline transducer is 1.6MPa

Out of this range need customized.

>>EMI (electromagnetic interference)

The ultrasonic flow meter, transducer and signal cable can be easily interfered by interference sources such as frequency changer, radio station, microwave station, GSM base station and high-tension cable. Please try to avoid these interference sources when choosing installation points.

The shield layer of flow meter, transducer and signal cable should be connected to earth.

Better to use isolated power supply. Do not use the same power supply with the frequency converter.

>>Instrument well

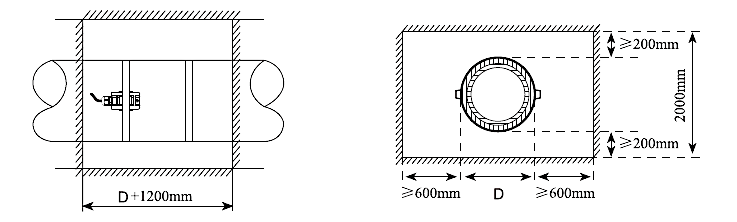

When measuring underground pipes or need to protect the measuring points, an instrument well is required. To ensure the enough installation space, the sizes of instrument well should meet the following requirements.

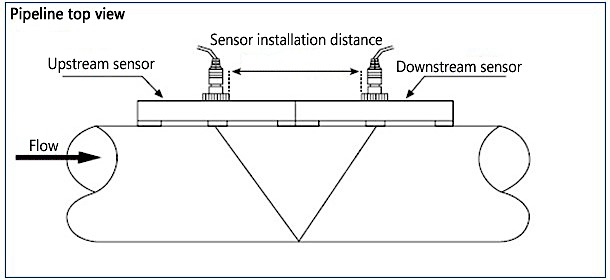

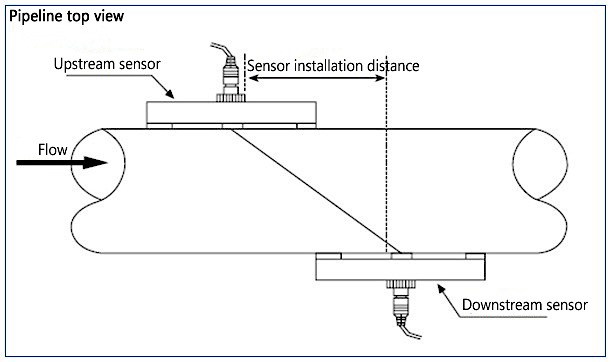

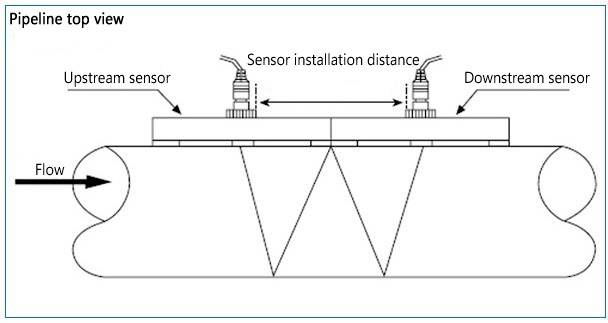

There are generally 3 probe installation methods for ultrasonic heat meters, namely Z method, V method and Parallel insertion.

Insertion type transducers are suitable for pipe sizes > 50mm.

>> V method : V method can be used for DN50mm – 300mm.

>> Z method: Z method can be used for all pipes > DN50mm.

>> Parallel insertion: If there is insufficient installation space or the transducers can be only installed on the top of pipeline, parallel insertion transducer will be a good choice. (Pipe size ≥ 300)

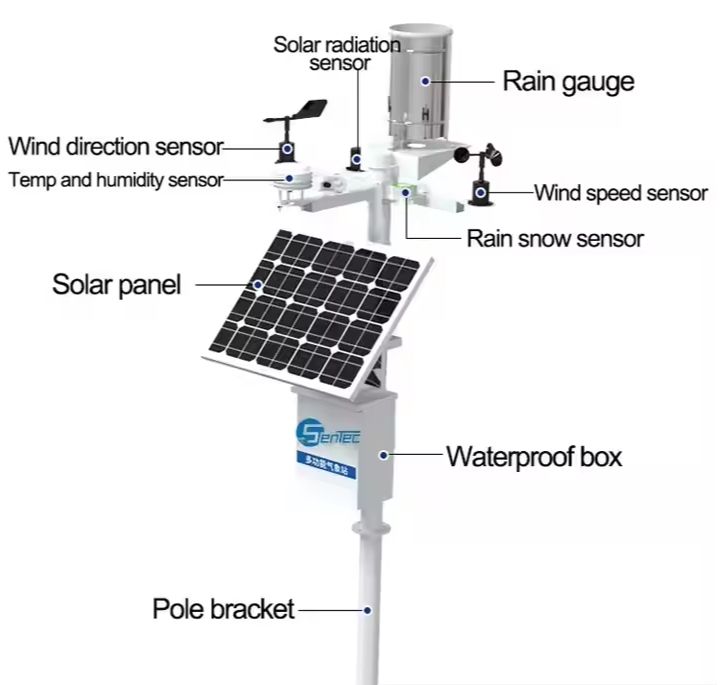

※Note: As one of the earliest flow meter manufacturer, SenTec provide a wide variety flow measurement solutions, such as differential pressure flow meters, Calorimetric Flowmeter, liquid flow sensor, Ultrasonic Level Transmitter, mass flow meter, Variable Area Flowmeter or Rotameter, Electromagnetic Flowmeter, Turbine Flowmeter, Vortex Flow Meter, Thermal Flowmeter, Coriolis Flowmeter, Mass Flowmeters, Open Channel Flowmeters etc.

For specific ultraosnic heat calorimeter meter price, please contact our sales engineer.