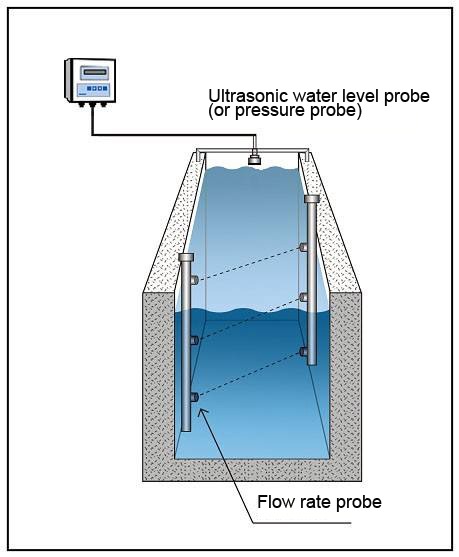

The ultrasonic open channel flowmeter uses the ultrasonic probe to measure the channel water level value by non-contact measurement, and then calculates the flow rate through the water level-flow conversion algorithm. The corresponding weir and groove (Parshall groove, rectangular weir, triangular weir, etc.) can be matched according to the site conditions of the channel, or it can be measured separately without the weir and groove. It is mainly used in farmland irrigation channels, enterprise sewage outlets, sewage treatment plants, ecological discharge flow monitoring of hydropower stations, etc.

Where are the ultrasonic open channel flowmeter used for?

Ultrasonic open channel flowmeters are widely used, mainly including urban water supply diversion canals; thermal power plant diversion and drainage canals, sewage treatment inflow and discharge canals, industrial and mining enterprise water discharge canals, hydropower station discharge ecological flow canals, water conservancy projects and agricultural irrigation channels.

ULTRASONIC OPEN CHANNEL FLOWMETER WORKING PRINCIPLE

In many non-full water, large flow (or small flow), and natural flow free water surface state, the flow of fluid is measured, which is called open channel flow detection. Due to the large or small flow of the open channel, there is often a certain degree of corrosiveness or some impurities in the fluid. It is very difficult to use a general pipeline flowmeter to detect the flow. For example, in the fields of industrial enterprise drainage, hospital wastewater, agricultural irrigation water, urban underground water drainage and other fields, open channel flow detection, especially non-contact ultrasonic open channel flowmeter, is the preferred flow monitoring instrument.

The ultrasonic open channel flowmeter is used with the corresponding parshall tank, triangular weir, rectangular weir and other weir tanks. It uses the propagation law of ultrasonic waves in the air to measure the liquid level height, and continuously transmits the liquid level information to the host computer. The system automatically measures the instantaneous flow and cumulative flow and stores them. This instrument adopts international advanced technology to complete flow detection without contact with fluid, and has perfect liquid level measurement function, control function, data transmission function and man-machine communication function. This machine is a flow measuring instrument integrating ultrasonic transceiver sensor, servo circuit, temperature compensation sensor and compensation circuit unit, accumulating host, display, control signal output and serial data or analog output unit.

How to choose Parshall Flume (PVC material, stainless steel material) for ultrasonic Open Channel Flow Meter ?

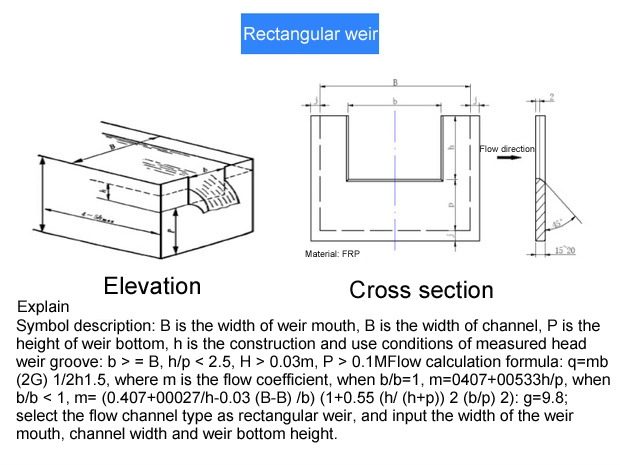

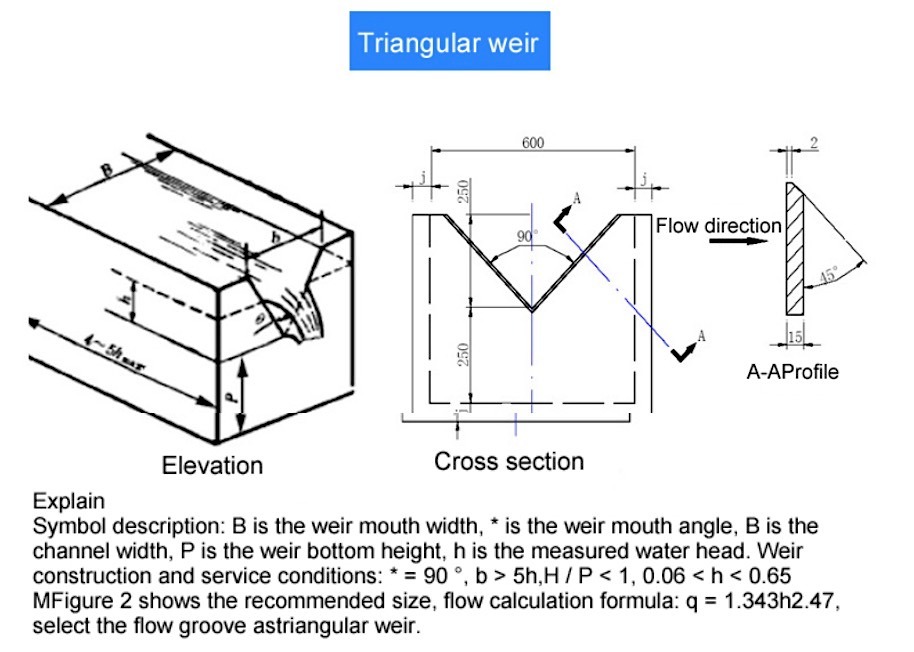

When choosing the type of weir and trough for measuring water, it is necessary to consider the size of the flow in the channel, the flow pattern of the water in the channel, and whether it can form a free flow. According to the different large flow, we can choose different weir grooves.

*The large flow rate is less than 40 liters/sec. It is recommended to use a right-angled triangular weir;

*It is recommended to use Parshall tank for more than 40 liters/sec;

*The upstream channel is short, and the large flow rate is greater than 40 liters/sec. It is recommended to use a rectangular weir.

What should be noted before installation a Ultrasonic open channel flowmeter ?

Best Installation notes for Ultrasonic open channel flowmeters:

1. Within the ultrasonic emission range, there should be no obstacles between the surface of the liquid to be measured and the

2. Between the probe emission surface and the highest water level > the blind area of the ultrasonic probe

3. The probe should be installed upstream of the weir tank

How to install and debug the Parshall tank ultrasonic open channel flowmeter?

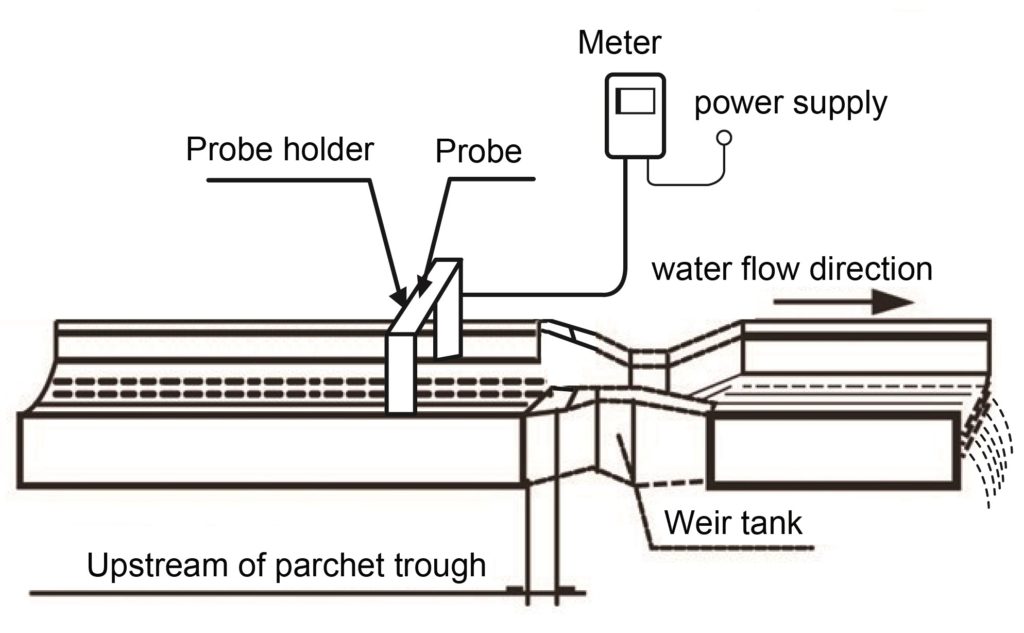

The physical quantity directly measured by the SUL815 ultrasonic open channel flowmeter is the liquid level. When used for open channel flow measurement, install a Parshall groove on the open channel. The Parshall weir tank converts the flow in the open channel into the level of the liquid level. The meter measures the water level in the parshall water weir tank, and then inversely calculates the flow according to the water level-flow relationship of the corresponding Parshall water weir tank.

The water level-flow relationship of the Parshall trough can be found in the National Metrology Verification Regulations “Open Channel Weir Slot Flowmeter” JJG711-90.

The instrument display part of the SUL815 ultrasonic open channel flowmeter should be installed indoors. The room should be well ventilated and free of corrosive gases. The meter is wall mounted. When hanging on the wall, first use a 300 x 400mm insulating board to make a dashboard, install the power switch, three-hole power socket, and grounding post. The switch is equipped with 0.5~3A fuse. There are four hanging holes on the back of the instrument, see Figure 6 for the dimensions. On the instrument panel, use four bolts to screw in the corresponding position. After the dial is fixed on the wall, use these four nails to hang the watch.

The probe of the ultrasonic open channel flowmeter can be installed directly above the water level observation point of the Parshall weir tank. The sounding side of the probe should be aimed at the water surface. You can use a spirit level to put the probe on the cover, and make the probe align with the water surface by leveling the cover. The observation point of the water level of the Parshall trough is located at a length of 2/3 of the constricted section of the throat;

When installing the probe, pay attention to the blind spot of the ultrasonic wave. The distance between the highest water surface and the bottom surface of the probe should be greater than 0.4m, which is equivalent to that the lower end of the calibration rod should not be less than 0.1m away from the highest water surface.

The probe bracket for installing the probe should be done when processing the Parshall weir tank. You can also directly use the angle steel as the beam, and install the probe on the beam.