Understanding Magnetostrictive Level Transmitters

Magnetostrictive level transmitters are cutting-edge devices that play a crucial role in accurately measuring liquid levels in petrochemical oil tanks. Unlike traditional level measurement methods, such as float and tape gauges, magnetostrictive level transmitters utilize advanced technology to provide real-time, precise data on the level of oil in storage tanks. These transmitters are equipped with a float that travels along a tube, using the principles of magnetostriction to determine the liquid level accurately.

Magnetostrictive level transmitters offer a myriad of benefits compared to traditional level measurement methods, such as enhanced accuracy, real-time data acquisition, and minimal maintenance requirements. These advantages make them the preferred choice for oil tank level detection in petrochemical facilities, contributing to improved operational efficiency and cost savings.

Problems with traditional measurement methods

In the petroleum and petrochemical refined oil circulation industry, most of the measurement of the oil content of the oil tank uses artificial climbing the tank and casting a ruler to measure. Use a metric steel tape measure with a heavy hammer or a scale with a scale to measure, manually record the reading, manually look up the table and convert it, and finally get the oil quantity data. This measurement method not only has high labor intensity, but also has unsafe factors, and cannot guarantee accuracy. In some places, capacitive / diffused silicon pressure level gauges are used for measurement. Due to the serious zero drift of this type of sensor, the measurement deviation is large, and the long-term working stability is poor, which is not welcomed by users. There are also places where isobaric membrane level gauges or mechanical float level gauges are used. However, because the membrane type liquid level gauge is greatly affected by temperature, and there is a problem of air leakage, the mechanical float liquid level gauge often appears to be stuck in the steel belt, so it has not been widely used.

How Magnetostrictive Level Transmitters Work

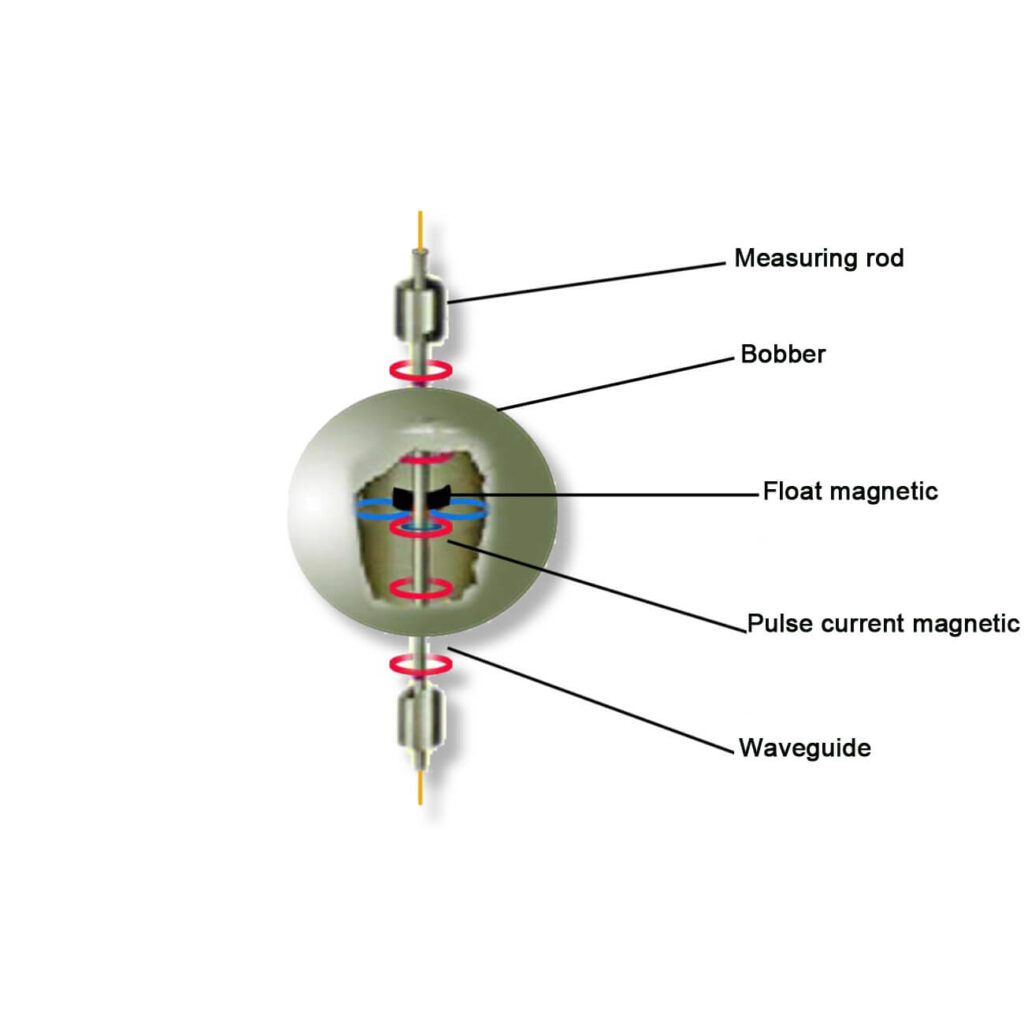

The structural part of the magnetostrictive liquid level sensor is composed of a stainless steel tube (rod), a magnetostrictive wire (waveguide wire), a movable float (with a permanent magnet inside), and the like.

When the sensor is operating, the circuit portion will excite a pulsed current on the waveguide wire that will generate a pulsed electromagnetic field around the waveguide wire as it propagates along the waveguide wire. A float is arranged outside the sensor rod, and the float can move up and down along the rod as the liquid level changes. There is a set of permanent magnetic rings inside the float. When the pulsed current magnetic field meets the magnetic ring magnetic field generated by the float, the magnetic field around the float changes so that the waveguide wire made of magnetostrictive material generates a torsional wave pulse at the position where the float is located. This pulse is along a fixed speed. The waveguide wire is transmitted back and detected by the detection mechanism. By measuring the time difference between the pulse current and the torsional wave, the position of the float, that is, the position of the liquid surface, can be accurately determined.

Magnetostrictive level transmitter technical performance indexes

a) Range: hard rod: 150 mm ~ 7000 mm, soft rod: up to 16000 mm;

b) Output form: 4-20mA; 0-5V; 0-10V; ± 5V; ± 10V; RS-485

c) Linear error: better than ± 0.05% FS; the error of sensor with range less than 300 m m is less than 150 μ M d) Repeatability: better than ± 0.002% FS

e) Output temperature drift: 50ppm / °C;

f) Product power consumption: ≤ 50mA;

g) Output ripple: ≤ 20mV;

h) With load capacity: 4-20mA output: with load capacity ≤ 500 Ω;

0-5V, 0-10V output: minimum controller load ≥ 5K Ω;

g) Power supply: 24V ± 2.4V. DC

Advantages of Using Magnetostrictive Level Transmitters in Petrochemical Oil Tanks

The utilization of magnetostrictive level transmitters in petrochemical oil tanks presents numerous advantages, making them an indispensable asset for the industry. One of the primary benefits is their unparalleled accuracy in measuring liquid levels. Unlike conventional methods that may be susceptible to errors and inaccuracies, magnetostrictive level transmitters provide precise readings, ensuring that oil levels are monitored with exceptional precision.

Furthermore, these transmitters offer real-time data acquisition, enabling petrochemical operators to access up-to-the-minute information regarding oil levels in storage tanks. This capability facilitates proactive decision-making and allows for prompt adjustments in operational processes, contributing to enhanced efficiency and productivity within the facility.

Additionally, the minimal maintenance requirements of magnetostrictive level transmitters make them a cost-effective solution for oil tank level detection. With reduced downtime and maintenance expenses, petrochemical companies can optimize their resources and focus on core business activities, ultimately leading to improved profitability and sustainability.

Incorporating magnetostrictive level transmitters into petrochemical oil tank operations not only ensures accurate level detection but also promotes operational excellence and cost-efficiency, making them a valuable investment for the industry.

Importance of Accurate Level Detection in Petrochemical Oil Tanks

Accurate level detection in petrochemical oil tanks is a critical aspect of ensuring operational safety, regulatory compliance, and efficient resource management within the industry. By utilizing advanced technologies such as magnetostrictive level transmitters, petrochemical companies can achieve precise measurement of liquid levels, providing a foundation for informed decision-making and streamlined operational processes.

The precise monitoring of oil levels in storage tanks is essential for preventing overfilling or underfilling, which can lead to costly operational disruptions, environmental hazards, and regulatory violations. Additionally, accurate level detection facilitates effective inventory management, enabling petrochemical facilities to optimize their resource utilization and minimize wastage, ultimately contributing to sustainable and responsible business practices.

Moreover, accurate level detection plays a pivotal role in ensuring the safety of petrochemical operations, as it enables proactive maintenance and intervention in the event of abnormal level fluctuations. This proactive approach to monitoring liquid levels mitigates the risk of potential hazards, enhancing the overall safety and reliability of petrochemical oil tank operations.

By recognizing the significance of accurate level detection in petrochemical oil tanks and embracing advanced technologies such as magnetostrictive level transmitters, industry professionals can elevate their operational standards and uphold the highest levels of safety, compliance, and efficiency.

Factors to Consider When Choosing a Magnetostrictive Level Transmitter for Oil Tank Level Detection

Selecting the right magnetostrictive level transmitter for oil tank level detection is a critical decision for petrochemical companies, as it directly impacts the accuracy, reliability, and efficiency of their liquid level measurement processes. When evaluating potential transmitters, several key factors should be taken into consideration to ensure that the chosen solution aligns with the operational requirements and objectives of the facility.

First and foremost, the measurement range of the magnetostrictive level transmitter should be carefully assessed to ensure that it encompasses the full spectrum of liquid levels within the oil tank. This consideration is essential for accurately monitoring fluctuations in oil levels and preventing potential overfilling or underfilling scenarios, which can lead to operational disruptions and safety hazards.

Additionally, the construction and material composition of the magnetostrictive level transmitter should be evaluated to ensure compatibility with the petrochemical environment, including resistance to corrosive substances, high temperatures, and other challenging operational conditions. Robust and durable construction is essential for maintaining the longevity and reliability of the transmitter in demanding industrial settings.

Furthermore, the integration capabilities of the magnetostrictive level transmitter with existing control and monitoring systems should be assessed to ensure seamless connectivity and data integration within the petrochemical facility’s operational infrastructure. This compatibility facilitates efficient data management and enables petrochemical operators to leverage the full potential of the transmitter for enhanced operational oversight and control.

By meticulously considering these factors and conducting thorough assessments of available magnetostrictive level transmitters, petrochemical companies can make informed decisions that align with their operational needs and contribute to the advancement of their liquid level measurement capabilities.

SenTec is an well-know Magnetostrictive Level Transmitters manufacturer, contact them for free model selection guide

Applications of Magnetostrictive Level Transmitters in the Petrochemical Industry

The applications of magnetostrictive level transmitters in the petrochemical industry are diverse, spanning across various operational areas where accurate liquid level measurement is essential. These transmitters are widely utilized in petrochemical oil tanks for monitoring and managing oil levels, offering a reliable and efficient solution for the industry’s critical operational requirements.

In addition to oil tank level detection, magnetostrictive level transmitters find extensive applications in chemical storage tanks, providing accurate and real-time measurement of liquid levels for a wide range of chemical substances. This versatility makes magnetostrictive level transmitters an indispensable tool for petrochemical companies, enabling them to maintain precise control over their liquid assets and ensure operational efficiency.

Furthermore, the use of magnetostrictive level transmitters extends to process vessels, where the accurate measurement of liquid levels is essential for maintaining optimal operating conditions and ensuring the integrity of chemical processes. By integrating these transmitters into their operational infrastructure, petrochemical facilities can enhance their process monitoring capabilities and uphold the highest standards of safety and efficiency.

The diverse applications of magnetostrictive level transmitters in the petrochemical industry underscore their versatility and reliability, positioning them as a fundamental component of operational excellence and regulatory compliance within the sector.

Installation and Maintenance Best Practices for Magnetostrictive Level Transmitters

The successful deployment and operation of magnetostrictive level transmitters in petrochemical oil tanks hinge upon the implementation of best practices for installation and maintenance. By adhering to industry-recommended guidelines and protocols, petrochemical companies can maximize the performance, reliability, and longevity of these critical devices, ensuring seamless and accurate liquid level measurement within their facilities.

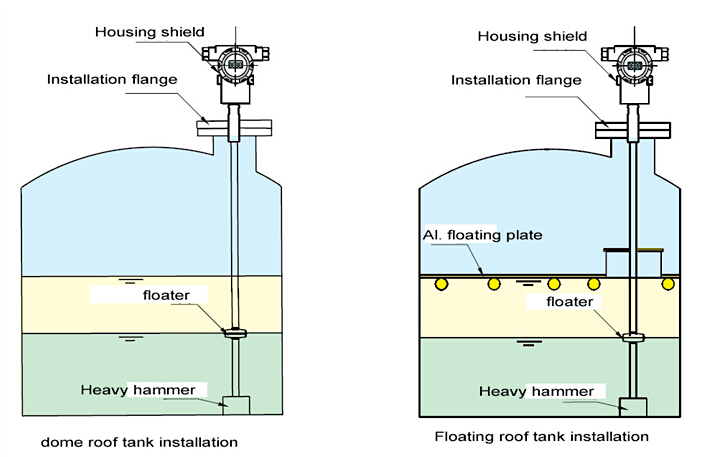

Here are some installation methods for Magnetostrictive Level Transmitters:

·Threaded installation

As shown in the figure, when the product is installed vertically, the installation slope shall not be more than 5 degrees; when installing the floating ball, the hemispheres marked with no (upper) shall be above the liquid level; there is a dead zone at both ends of the measuring rod; when the locking ring is fixed, the lower end shall be flush with the bottom end of the rod.

This method is suitable for most liquid tank measurement. The connecting flange provided by the manufacturer or the flange specially customized by the user can be selected, and the installation thread of the liquid level sensor can be screwed directly into the flange.

This method is suitable for measuring height-adjustable can open and sealed cans.

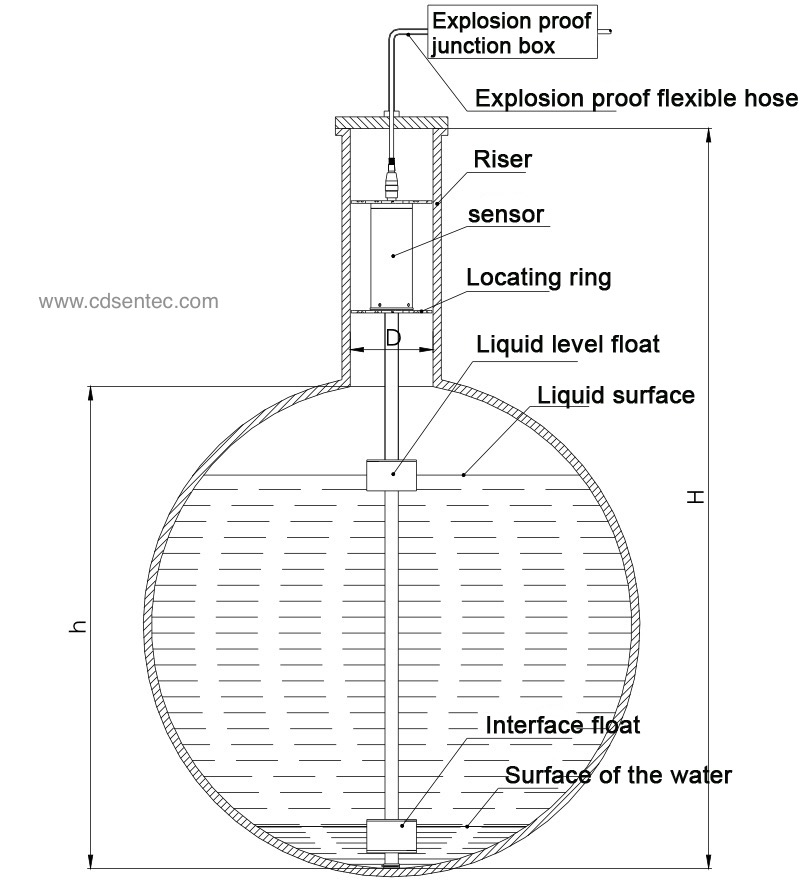

·Positioning ring installation

The sensor rod touches the bottom of the tank, and the positioning ring of the electronic warehouse is used to prevent the sensor from swinging. The sensor electronic warehouse and the outgoing cable are in the oil tank. Note:

h = tank height

H = h + riser height

D = Φ100mm Standpipe height ≥ 300mm

Suspended installation

The sensor is hung under the flange of the tank mouth, and the measuring rod is kept at a certain distance from the bottom of the tank (2~5mm). The positioning ring of the electronic warehouse is used to prevent the sensor from swinging. The sensor electronic warehouse and the outgoing cable are in the oil tank.

Note:

h = tank height

H = h + riser height D=Φ100mm

Standpipe height ≥300mm

Case Studies Showcasing the Benefits of Using Magnetostrictive Level Transmitters in Petrochemical Oil Tanks

The real-world application of magnetostrictive level transmitters in petrochemical oil tanks has yielded compelling results, demonstrating the tangible benefits and advantages that these advanced devices offer to the industry. Several case studies showcase the successful integration of magnetostrictive level transmitters into petrochemical facilities, highlighting their impact on operational efficiency, safety, and regulatory compliance.

In a prominent petrochemical refinery, the implementation of magnetostrictive level transmitters revolutionized the facility’s oil tank level detection processes, providing accurate and real-time measurements of liquid levels. This enhanced visibility into the status of oil storage tanks enabled the refinery to optimize its inventory management, prevent potential overfilling incidents, and maintain compliance with stringent regulatory requirements, ultimately enhancing operational safety and efficiency.

Similarly, in a petrochemical storage terminal, the adoption of magnetostrictive level transmitters facilitated proactive monitoring of liquid levels in diverse chemical storage tanks, ensuring precise control over valuable assets and minimizing the risk of operational disruptions. The transmitters’ reliability and accuracy empowered the terminal to streamline its operational processes, optimize resource utilization, and uphold the highest standards of environmental stewardship, reinforcing their position as a critical asset for the industry.

Furthermore, in a petrochemical production facility, the utilization of magnetostrictive level transmitters in process vessels enabled the precise measurement of liquid levels, contributing to the integrity and efficiency of chemical processes. The transmitters’ robust performance and adaptability in challenging operational environments underscored their instrumental role in promoting operational excellence and safety within the facility.

These case studies underscore the transformative impact of magnetostrictive level transmitters in petrochemical oil tanks, validating their status as a fundamental technology for accurate, efficient, and reliable liquid level measurement within the industry.

Conclusion

In conclusion, the utilization of magnetostrictive level transmitters in petrochemical oil tanks offers unparalleled advantages, including enhanced accuracy, real-time data acquisition, and minimal maintenance requirements. By harnessing the principles of magnetostriction, these advanced devices provide a reliable and efficient solution for oil tank level detection, contributing to improved operational efficiency, safety, and regulatory compliance within the petrochemical industry.

The diverse applications of magnetostrictive level transmitters in petrochemical facilities underscore their versatility and reliability, positioning them as a fundamental component of operational excellence and regulatory compliance within the sector. Moreover, the successful integration of magnetostrictive level transmitters into petrochemical operations has been exemplified through compelling case studies, showcasing their transformative impact on operational efficiency, safety, and environmental stewardship.

As the petrochemical industry continues to prioritize accurate liquid level measurement and operational excellence, the adoption of magnetostrictive level transmitters emerges as an essential strategy for advancing these critical objectives. By embracing the advantages of magnetostrictive level transmitters and leveraging their