Understanding Wireless Temperature Transmitter

In today’s industrial landscape, the use of wireless temperature transmitter is revolutionizing the way temperature data is collected, monitored, and managed. These advanced devices offer a range of benefits over traditional wired solutions, providing increased efficiency, flexibility, and cost-effectiveness. Wireless temperature transmitters are designed to accurately measure and transmit temperature data without the need for physical wiring, enabling real-time monitoring and control across various industrial applications. Understanding how wireless temperature transmitters function and their key components is essential for harnessing their full potential in industrial settings.

Wireless temperature transmitters consist of a sensor, a transmitter, and a receiver, allowing for seamless communication of temperature data without the limitations of wired connections. The sensor is responsible for accurately measuring the temperature of the surrounding environment, while the transmitter converts this data into a digital signal for transmission. The receiver, typically connected to a central monitoring system, captures and processes the transmitted data, providing real-time insights into temperature variations. This wireless approach eliminates the need for complex wiring infrastructure, simplifying installation and enabling the monitoring of temperature in remote or difficult-to-access locations.

The integration of wireless technology in temperature transmitters has opened up new possibilities for industrial automation and process control. By leveraging wireless connectivity, organizations can achieve greater flexibility in deploying temperature monitoring solutions across their facilities. Whether it’s monitoring temperature in a large-scale manufacturing plant or in a remote field location, wireless temperature transmitters offer the agility to adapt to diverse operational requirements. Additionally, the ability to transmit data wirelessly enhances the overall reliability of temperature monitoring systems by minimizing the risk of signal interference and cable damage, ensuring consistent and accurate temperature data collection.

Advantages of Using Wireless Temperature Transmitters

The adoption of wireless temperature transmitters presents a myriad of advantages for industrial operations, ranging from increased productivity to enhanced safety and cost savings. One of the primary benefits is the elimination of complex wiring infrastructure, which significantly reduces installation time and costs. Traditional wired temperature monitoring systems often require extensive cabling and conduit installation, leading to higher material and labor expenses. In contrast, wireless temperature transmitters offer a more streamlined and cost-effective deployment, especially in retrofit or expansion projects where running new wires can be challenging.

Another key advantage of wireless temperature transmitters is their ability to provide real-time data accessibility and remote monitoring capabilities. With wireless connectivity, operators and maintenance personnel can access temperature data from any location with internet or network connectivity. This not only facilitates proactive decision-making but also enables swift response to temperature fluctuations or anomalies, thereby improving operational efficiency and minimizing downtime. Moreover, the seamless integration of wireless temperature transmitters with existing industrial automation systems enhances overall process control and optimization, leading to improved production quality and throughput.

The inherent flexibility of wireless temperature transmitters allows for dynamic sensor placement and easy reconfiguration, catering to evolving operational needs. This adaptability is particularly valuable in environments where equipment layout and processes may change over time, as it enables swift adjustments to temperature monitoring strategies without the constraints of fixed wiring. Additionally, wireless temperature transmitters offer scalability, allowing organizations to expand their temperature monitoring infrastructure as their operations grow, without the limitations imposed by physical cabling. This scalability ensures that industrial facilities can effectively accommodate future expansion and technological advancements without overhauling their existing temperature monitoring systems.

Applications of Wireless Temperature Transmitters

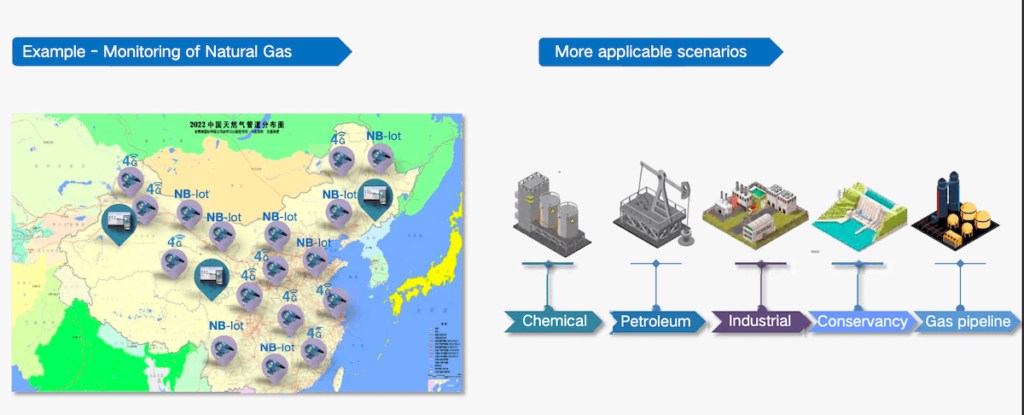

The versatility of wireless temperature transmitters makes them well-suited for a wide array of industrial applications, spanning across various sectors such as manufacturing, energy, pharmaceuticals, and food processing. In manufacturing environments, wireless temperature transmitters play a critical role in ensuring consistent product quality and process efficiency. By accurately monitoring temperature variations in production equipment and storage facilities, manufacturers can uphold stringent quality standards and compliance requirements, while also optimizing energy usage and minimizing waste.

In the energy sector, wireless temperature transmitters are instrumental in monitoring the temperature of critical assets such as turbines, generators, and transformers. The real-time data provided by these transmitters enables proactive maintenance and condition monitoring, helping to prevent costly equipment failures and downtime. Furthermore, wireless temperature transmitters are invaluable in pharmaceutical and food processing industries where precise temperature control is essential for preserving product integrity and meeting regulatory standards. From cold chain logistics to storage facilities, wireless temperature transmitters ensure that temperature-sensitive products are maintained within optimal conditions throughout the supply chain.

The deployment of wireless temperature transmitters extends beyond traditional industrial settings, finding applications in research laboratories, environmental monitoring, and HVAC systems. In research and development laboratories, these transmitters facilitate accurate temperature measurements in controlled environments, supporting scientific experiments and process optimization. Similarly, environmental monitoring initiatives leverage wireless temperature transmitters to track temperature variations in natural habitats, industrial emissions, and climate-controlled facilities. In HVAC systems, wireless temperature transmitters enable efficient climate control and energy management, contributing to improved occupant comfort and building sustainability.

Selecting the Right Wireless Temperature Transmitter for Your Needs

Choosing the appropriate wireless temperature transmitter for specific industrial requirements is crucial to achieving optimal performance and reliability. Several factors must be considered when selecting a wireless temperature transmitter, including the environmental conditions, measurement accuracy, communication range, and power source. The operating environment, whether it’s an indoor manufacturing facility or an outdoor field site, dictates the level of ruggedness and environmental protection required for the wireless temperature transmitter. For harsh or hazardous environments, explosion-proof temperature transmitters are essential to ensure safe and reliable temperature monitoring.

Measurement accuracy is a critical consideration, particularly in industries where precise temperature control is paramount. High-accuracy wireless temperature transmitters equipped with advanced sensor technologies and calibration capabilities are essential for applications such as pharmaceutical manufacturing, precision engineering, and research laboratories. Additionally, the communication range of the wireless temperature transmitter must align with the spatial requirements of the monitoring area. For expansive industrial facilities or remote installations, temperature transmitters with extended wireless coverage and robust signal penetration capabilities are essential to maintain seamless connectivity.

The power source of the wireless temperature transmitter is another pivotal aspect to evaluate, as it directly impacts maintenance requirements and operational longevity. While battery-powered wireless temperature transmitters offer flexibility and ease of installation, they require periodic battery replacement or recharging, which can be a logistical challenge in certain industrial settings. Alternatively, solar-powered or self-powered wireless temperature transmitters provide sustainable and maintenance-free operation, making them ideal for remote and hard-to-access locations where regular maintenance is impractical. By carefully evaluating these factors and consulting with experienced industrial automation professionals, organizations can ensure that they select the right wireless temperature transmitter that aligns with their specific operational needs and environmental conditions.

SenTec provide both battery self-powered and solar-power wireless temperature transmitter. Contact us to know more.

Considerations for Installation and Maintenance

The successful deployment of wireless temperature transmitters hinges on meticulous planning, proper installation, and proactive maintenance practices. Prior to installation, a thorough site survey should be conducted to evaluate the optimal sensor placement, wireless signal strength, and potential sources of interference. The chosen installation locations should facilitate unobstructed transmission of temperature data while minimizing exposure to environmental hazards or physical damage. It’s imperative to adhere to manufacturer guidelines and industry best practices during the installation process to ensure the reliability and longevity of the wireless temperature transmitter system.

As with any industrial equipment, regular maintenance is vital to preserving the performance and accuracy of wireless temperature transmitters. Periodic inspection of sensor elements, signal integrity, and power supply should be conducted to identify and address any potential issues proactively. Additionally, firmware updates and calibration checks should be performed in accordance with the manufacturer’s recommendations to maintain measurement accuracy and compliance with industry standards. Implementing a comprehensive maintenance schedule and documentation process is essential to track the performance of wireless temperature transmitters and address any anomalies in a timely manner, thereby minimizing operational disruptions and ensuring continuous temperature monitoring capabilities.

Features to Look for in Wireless Temperature Transmitters

When evaluating wireless temperature transmitters, specific features and capabilities should be prioritized to maximize their effectiveness and suitability for industrial applications. Advanced signal processing algorithms and noise filtering mechanisms are essential for ensuring the accuracy and reliability of temperature data transmission, especially in environments prone to electromagnetic interference or signal degradation. Furthermore, the integration of smart temperature transmitter technologies, such as self-diagnostic capabilities and predictive maintenance functions, enhances the overall operational efficiency and reduces the risk of unexpected equipment failures.

Robust communication protocols and encryption mechanisms are critical features to safeguard the integrity and security of transmitted temperature data. Modern wireless temperature transmitters often leverage industry-standard encryption protocols and secure communication channels to prevent unauthorized access and data tampering. Additionally, seamless integration with industrial communication networks, such as Modbus or HART, enables interoperability with existing control systems and facilitates data exchange with centralized monitoring and control platforms.

In hazardous environments where the presence of flammable gases or combustible dust is a concern, explosion-proof wireless temperature transmitters are essential to ensure operational safety and compliance with regulatory standards. These specialized transmitters are designed to mitigate the risk of ignition and withstand potentially explosive atmospheres, making them indispensable for industries such as oil and gas, chemical processing, and mining. Furthermore, the availability of temperature transmitters with wide operating temperature ranges and robust environmental protection features is crucial for addressing the diverse and challenging conditions encountered in industrial operations.

Wireless Temperature Transmitters in Hazardous Environments

The utilization of wireless temperature transmitters in hazardous environments introduces a new paradigm in safety, efficiency, and compliance for industries operating in potentially explosive atmospheres. Traditional wired temperature monitoring solutions in hazardous areas pose inherent risks associated with the use of electrical wiring and instrumentation, as they can act as potential sources of ignition in the presence of flammable substances. In contrast, wireless temperature transmitters designed for hazardous locations offer a safer and more reliable alternative, enabling organizations to maintain critical temperature monitoring capabilities without compromising safety.

Explosion-proof wireless temperature transmitters adhere to stringent industry standards and certification requirements, ensuring that they are intrinsically safe and suitable for use in hazardous areas classified as Zone 0, Zone 1, or Zone 2. These transmitters are engineered to withstand the challenges posed by volatile environments, featuring robust enclosures, flameproof construction, and specialized sealing techniques to prevent the ingress of hazardous substances. By leveraging wireless technology in hazardous areas, organizations can minimize the complexity and risks associated with traditional wiring methods while maintaining compliance with regulatory mandates and industry-specific safety standards.

The deployment of wireless temperature transmitters in hazardous environments extends beyond mere compliance to encompass enhanced operational efficiency and maintenance practices. The elimination of complex wiring infrastructure reduces installation time, cost, and the potential for wiring-related failures, streamlining the implementation of temperature monitoring solutions in challenging industrial settings. Additionally, the seamless integration of wireless temperature transmitters with advanced asset management and condition monitoring systems empowers organizations to proactively assess the health and performance of critical assets, mitigating the risk of equipment malfunctions and unplanned downtime.

Comparison of Different Wireless Temperature Transmitters

The market for wireless temperature transmitters encompasses a diverse range of products with varying features, performance capabilities, and suitability for specific industrial applications. Conducting a comprehensive comparison of different wireless temperature transmitters is essential for organizations to make informed decisions and select the most appropriate solution for their operational requirements. Key factors to consider in the comparison include measurement accuracy, environmental ratings, wireless communication protocols, power options, and compatibility with industry standards and control systems.

High-accuracy wireless temperature transmitters equipped with advanced sensor technologies and calibration capabilities are essential for applications such as pharmaceutical manufacturing, precision engineering, and research laboratories. Additionally, the communication range of the wireless temperature transmitter must align with the spatial requirements of the monitoring area. For expansive industrial facilities or remote installations, temperature transmitters with extended wireless coverage and robust signal penetration capabilities are essential to maintain seamless connectivity.

The power source of the wireless temperature transmitter is another pivotal aspect to evaluate, as it directly impacts maintenance requirements and operational longevity. While battery-powered wireless temperature transmitters offer flexibility and ease of installation, they require periodic battery replacement or recharging, which can be a logistical challenge in certain industrial settings. Alternatively, solar-powered or self-powered wireless temperature transmitters provide sustainable and maintenance-free operation, making them ideal for remote and hard-to-access locations where regular maintenance is impractical. By carefully evaluating these factors and consulting with experienced industrial automation professionals, organizations can ensure that they select the right wireless temperature transmitter that aligns with their specific operational needs and environmental conditions.

Future Trends in Wireless Temperature Transmitters

The evolution of wireless temperature transmitters is poised to encompass several key trends and advancements that will further enhance their capabilities and proliferation across diverse industrial sectors. One of the emerging trends is the integration of IoT (Internet of Things) technology in wireless temperature transmitters, enabling seamless connectivity with cloud-based platforms and advanced analytics tools. By harnessing IoT capabilities, wireless temperature transmitters can facilitate predictive maintenance, data-driven insights, and remote monitoring functionalities, empowering organizations to optimize their operational processes and asset management strategies.

The convergence of wireless temperature transmitters with artificial intelligence and machine learning algorithms is set to revolutionize temperature monitoring and control practices. By leveraging AI-driven analytics, these transmitters can identify patterns, anomalies, and potential equipment failures based on temperature data, enabling proactive intervention and optimization of industrial processes. Furthermore, the integration of smart temperature transmitter technologies, such as self-diagnostic capabilities and predictive maintenance functions, enhances the overall operational efficiency and reduces the risk of unexpected equipment failures.

Another noteworthy trend in wireless temperature transmitters is the advancement of energy harvesting and self-powered technologies, enabling these transmitters to operate autonomously without the need for external power sources. By leveraging ambient energy sources such as vibration, thermal differentials, or solar radiation, self-powered wireless temperature transmitters offer sustainable and maintenance-free operation, making them ideal for remote and challenging environments where regular maintenance is impractical. This trend aligns with the growing emphasis on sustainability and energy efficiency in industrial operations, driving the adoption of environmentally friendly and self-sustaining monitoring solutions.

Conclusion

In conclusion, the widespread adoption of wireless temperature transmitters is reshaping the industrial landscape by delivering enhanced efficiency, safety, and operational flexibility. These advanced devices offer a range of benefits over traditional wired solutions, empowering organizations to achieve seamless temperature monitoring, proactive maintenance, and real-time data accessibility. From manufacturing facilities to hazardous environments, the applications of wireless temperature transmitters are diverse and impactful, supporting critical processes and ensuring regulatory compliance. As the industry continues to embrace wireless technology and smart sensor innovations, the future of wireless temperature transmitters is poised to encompass IoT integration, AI-driven analytics, and sustainable self-powered capabilities, further elevating their role in industrial automation and asset management.

CTA

To explore the latest advancements in wireless temperature transmitters and optimize your industrial temperature monitoring capabilities, consult with our experienced team of automation professionals today. Embrace the future of industrial efficiency with wireless technology and unlock new possibilities for process control, safety, and productivity. Contact us to discover tailored solutions that align with your specific operational needs and elevate your temperature monitoring infrastructure to new heights.