Wood Processing Instrumentation

Wood processing instrumentation refers to the sensor and equipment used in the processing and manufacturing of wood products. Wood processing instrumentation plays a vital role in optimizing productivity, ensuring product quality, and maintaining worker safety in the wood processing industry.

Table of Contents

Background: Wood processing for paper industry

Wood processing in the paper industry involves the conversion of wood fibers into pulp, which is then used to produce various paper-based products. The process includes several steps such as debarking, chipping, screening, crushing, and storing the wood. Specialized equipment is used throughout the process, including chippers, pulpers, digesters, refiners, and Fourdrinier machines. Chippers are used to break down the wood into small chips, while pulpers and digesters are used to separate the cellulose fibers from the wood.

Process instrumentation solutions for wood product manufacturing

Process instrumentation solutions for wood product manufacturing involve the use of specialized instruments and equipment to monitor and control various parameters during the wood processing and manufacturing processes. These solutions are essential for ensuring product integrity, optimizing productivity, and maintaining workplace safety. As a leading provider of process instrumentation solutions for the wood product manufacturing industry, SenTec offer a wide range of instruments and equipment for monitoring lumber moisture levels, automated manufacturing processes, pressure levels, temperature levels, and storage vessel levels.

Wood processing instrumentation: pressure gauges and transmitters

Pressure gauges and transmitters are essential instruments used in wood processing automation. These instruments monitor and control pressure levels in processing equipment to ensure safe and efficient manufacturing processes. By accurately measuring pressure, they help prevent overpressure situations, which can lead to equipment damage or accidents. Pressure gauges and transmitters provide real-time data on pressure levels, allowing operators to make necessary adjustments and maintain optimal operating conditions. SenTec is reputable suppliers of pressure gauges and transmitters, offering a wide range of products to meet the specific needs of the wood product manufacturing industry.

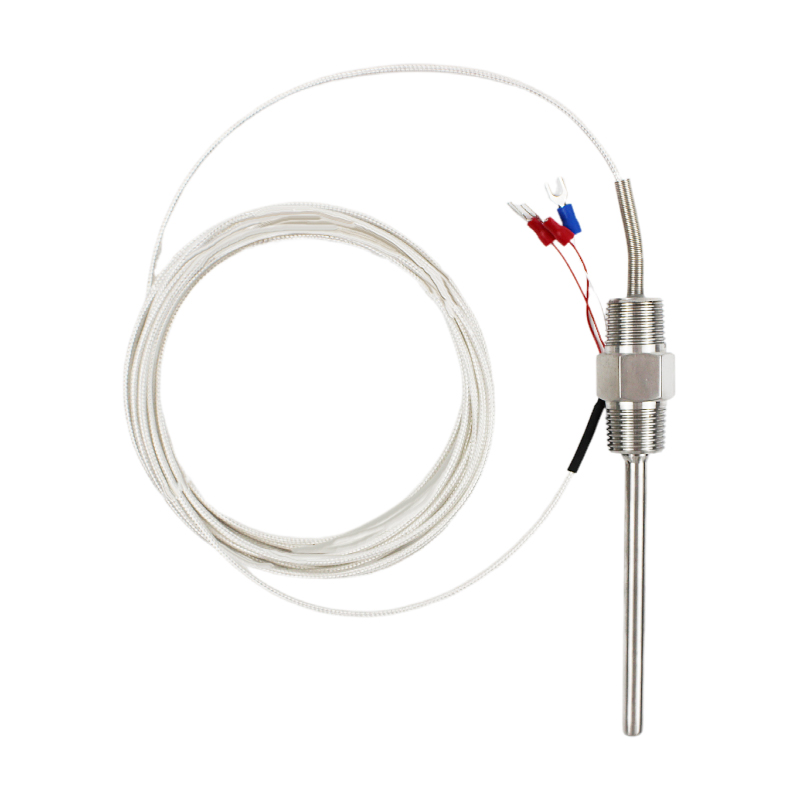

Wood processing instrumentation: temperature sensor and controller

Wood processing instrumentation includes temperature sensors and controllers. These instruments are essential for monitoring and controlling temperature levels in wood processing equipment. Temperature sensors are used to measure the temperature of various components and materials involved in the process, such as molten lead, molten aluminum, and forging steel. Temperature controllers are used to regulate and maintain the desired temperature range for optimal wood processing. They help ensure product integrity, control the drying process, and prevent any potential safety hazards. With the use of temperature sensors and controllers, operators can accurately monitor and adjust temperature settings to achieve efficient and high-quality wood processing results.

Subscribe To get new products and solutions

Wood processing instrumentation: level sensor and transmitter

Wood processing instrumentation includes various instruments such as level sensors and transmitters. These instruments are crucial for monitoring and controlling the level of wood chips in dry solid bins or silos during the wood processing process. They provide reliable continuous level measurement, ensuring efficient and safe manufacturing processes.

SenTec, as a reputable suppliers, offer a wide range of level indicators specifically designed for the wood industry. Our level sensors and transmitters for powders and bulk materials include rotating paddle switches, ultrasonic instrumentation, non-contacting radars, and capacitance probe switches.

These level sensor indicators cater to different tasks in the storage, processing, and transportation of bulk solids in the wood industry. They enable accurate and precise monitoring of wood chip and sawdust silos, bunkers for pressboard production, loading bellows, transfer stations, and more.

Latest Posts

Flow Rate and Pressure Relationship Formula: A Simple Guide That Actually Makes Sense

Absolute vs Gauge Pressure: Avoiding Common Measurement Mistakes