Ultrasonic flow meter is innovative devices used to measure the flow of liquid or gas in a variety of industries. These meters have gained popularity due to their non-intrusive nature, high accuracy, and versatility. They operate on the principle of ultrasonic waves to determine the velocity of the fluid, making them suitable for a wide range of applications. Ultrasonic flow meters offer an efficient and cost-effective solution for flow measurement, making them a preferred choice for many industries.

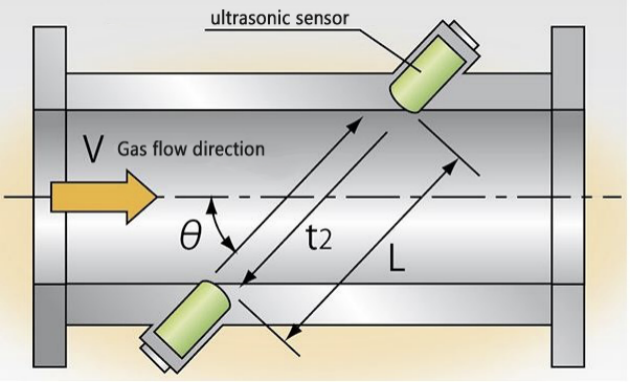

The design of ultrasonic flow meters is based on the transit-time or Doppler effect principle, where ultrasonic waves are transmitted through the fluid and the resulting time difference or frequency shift is used to calculate the flow rate. This technology has revolutionized flow measurement by providing a non-intrusive and reliable method for monitoring fluid flow. With the ability to measure various types of fluids, including clean, dirty, aerated, or corrosive liquids, ultrasonic flow meters have become an indispensable tool in process industries, water management, and energy sectors.

The evolution of ultrasonic flow meters has led to the development of different types, each catering to specific application requirements. Understanding the various types of ultrasonic flow meters and their unique features is essential for selecting the most suitable device for a particular application.

Types of Ultrasonic Flow Meters

Transit-Time Ultrasonic Flow Meters

Transit-time ultrasonic flow meters utilize pairs of ultrasonic transducers to measure the time it takes for an ultrasonic signal to travel between the transducers against and with the flow of the fluid. By comparing the transit times, the flow velocity can be accurately determined. This type of ultrasonic flow meter is ideal for clean and homogeneous liquids, offering high accuracy and repeatability.

Doppler Ultrasonic Flow Meters

Doppler ultrasonic flow meters operate on the principle of frequency shift caused by the reflection of ultrasonic waves from suspended particles or gas bubbles in the flowing fluid. The frequency shift is used to calculate the flow velocity. This type of flow meter is suitable for fluids with particulates or bubbles, making it a preferred choice for wastewater, slurry, and industrial processes where the fluid may not be homogeneous.

Hybrid Ultrasonic Flow Meters

Hybrid ultrasonic flow meters combine the principles of both transit-time and Doppler technologies to provide accurate measurements across a wide range of fluid conditions. By integrating the advantages of both methods, hybrid ultrasonic flow meters offer versatility and reliability, making them suitable for challenging flow measurement applications.

Understanding the different types of ultrasonic flow meters enables users to make informed decisions based on the specific characteristics of the fluid and the operational requirements.

How Does an Ultrasonic Flow Meter Work?

The operation of an ultrasonic flow meter involves the generation and detection of ultrasonic waves to determine the flow velocity of the fluid. The basic working principle varies depending on the type of ultrasonic flow meter being used.

For transit-time ultrasonic flow meters, pairs of transducers are positioned opposite each other on the pipe, and ultrasonic pulses are transmitted alternately with and against the flow. The time taken for the ultrasonic signals to travel between the transducers is measured, and the flow velocity is calculated based on the time difference.

In the case of Doppler ultrasonic flow meters, the emitted ultrasonic waves encounter particles or bubbles in the fluid, leading to a frequency shift in the reflected waves. By analyzing the frequency shift, the flow velocity can be determined, providing a reliable method for flow measurement in challenging fluid conditions.

Hybrid ultrasonic flow meters combine the principles of both transit-time and Doppler technologies to enhance the measurement capabilities. By utilizing a combination of transit-time and Doppler techniques, these flow meters can adapt to varying fluid characteristics and provide accurate flow measurements across a wide range of applications.

The non-intrusive nature of ultrasonic flow meters, along with their ability to measure a diverse range of fluids, makes them a versatile and efficient solution for flow measurement in numerous industries.

Understanding Clamp-On Ultrasonic Flow Meters

Clamp-on ultrasonic flow meters, also known as non-invasive or external ultrasonic flow meters, offer a unique solution for flow measurement without the need to cut into the pipe or interrupt the flow. These meters utilize transducers that are clamped onto the external surface of the pipe, emitting and receiving ultrasonic signals through the pipe wall. The transit-time method is commonly used in clamp-on ultrasonic flow meters to measure the flow velocity without direct contact with the fluid.

The non-intrusive nature of clamp-on ultrasonic flow meters makes them suitable for retrofitting existing pipelines and monitoring flow in applications where traditional inline flow meters are impractical. By simply attaching the transducers to the pipe surface and configuring the meter for the specific pipe material and diameter, users can quickly implement flow measurement without disrupting the existing piping infrastructure.

Clamp-on ultrasonic flow meters are particularly valuable for temporary flow monitoring, rental equipment applications, and scenarios where minimal installation time and flexibility are essential. Their versatility and ease of use make them a convenient choice for a wide range of industries, including water management, HVAC systems, and process optimization.

Advantages of ultrasonic flowmeter

Ultrasonic flow meters offer several advantages that contribute to their widespread adoption in industrial and commercial applications.

- Non-Intrusive Measurement: Ultrasonic flow meters do not require direct contact with the fluid, eliminating the need for cutting into the pipe or interrupting the flow. This non-intrusive nature reduces installation time and maintenance efforts, making ultrasonic flow meters a convenient and cost-effective choice for flow measurement.

- Wide Range of Fluid Compatibility: Ultrasonic flow meters can accurately measure various types of fluids, including clean liquids, slurry, wastewater, and corrosive chemicals. Their ability to adapt to different fluid conditions makes them suitable for diverse industrial processes and environmental monitoring applications.

- High Accuracy and Repeatability: The advanced technology employed in ultrasonic flow meters ensures precise measurement of flow velocity, leading to high accuracy and repeatability in flow rate calculations. This accuracy is essential for optimizing process efficiency and maintaining quality standards in industrial operations.

- Minimal Maintenance Requirements: With no moving parts and minimal internal components, ultrasonic flow meters have low maintenance requirements, reducing downtime and operational costs. This reliability makes them an attractive choice for continuous flow monitoring and control.

- Bi-Directional Flow Measurement: Many ultrasonic flow meters are capable of measuring flow in both directions, providing valuable insights into fluid dynamics and allowing for bidirectional flow control in pipelines and processes.

The combination of these advantages positions ultrasonic flow meters as a preferred choice for flow measurement in a wide range of industries, including oil and gas, water utilities, chemical processing, and HVAC systems.

Applications of Ultrasonic Flow Meters

The versatility and reliability of ultrasonic flow meters make them suitable for diverse applications across various industries.

- Industrial Process Monitoring: Ultrasonic flow meters are used in industrial processes such as chemical manufacturing, food and beverage production, and pharmaceutical processing to monitor the flow of liquids and gases. Their non-intrusive design and high accuracy make them valuable instruments for optimizing production efficiency and ensuring consistent product quality.

- Water and Wastewater Management: Ultrasonic flow meters play a crucial role in water utilities and wastewater treatment facilities, where accurate flow measurement is essential for resource management and environmental compliance. These flow meters provide real-time data for monitoring water usage, detecting leaks, and controlling the flow of water and wastewater in distribution networks and treatment plants.

- Energy and Utilities: In the energy sector, ultrasonic flow meters are utilized for measuring the flow of natural gas, steam, and other utilities. Their ability to handle a wide range of fluid conditions and provide accurate measurements contributes to efficient energy management and cost-effective operations.

- HVAC and Building Systems: Ultrasonic flow meters are integrated into heating, ventilation, and air conditioning (HVAC) systems to monitor the flow of water and other fluids for temperature regulation and energy conservation. Their non-intrusive installation and high accuracy make them ideal for building automation and energy-efficient HVAC solutions.

By catering to these diverse applications, ultrasonic flow meters contribute to improved operational performance, resource conservation, and regulatory compliance in various industries.

How to Use an Ultrasonic Flow Meter

Using an ultrasonic flow meter involves a series of steps to ensure accurate and reliable flow measurement.

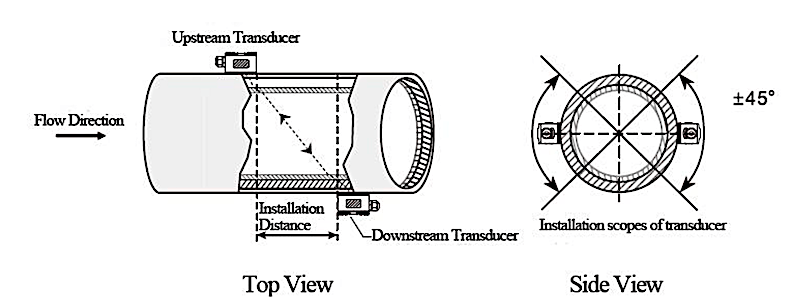

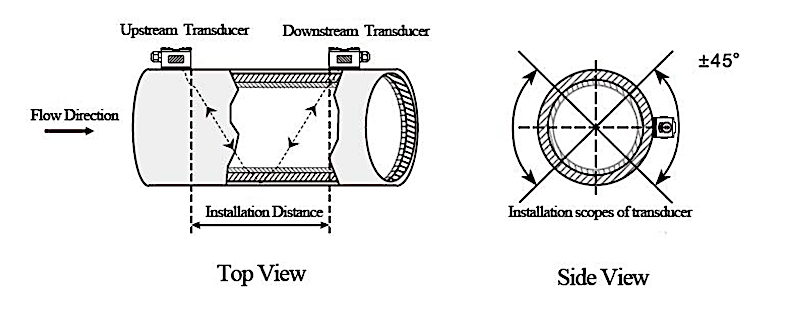

- Proper Installation: Positioning the ultrasonic transducers at the correct locations on the pipe is crucial for accurate flow measurement. Following the manufacturer’s guidelines for installation and ensuring proper alignment of the transducers are essential for optimal performance.

- Calibration and Configuration: Calibrating the ultrasonic flow meter according to the specific fluid properties and flow conditions is necessary to achieve accurate measurements. Configuring the device parameters, such as pipe diameter, fluid type, and measurement units, ensures that the flow meter operates effectively for the intended application.

- Monitoring and Data Analysis: Once the ultrasonic flow meter is installed and calibrated, it continuously monitors the flow of the fluid, providing real-time data for analysis. Understanding the flow patterns and variations in the measured parameters enables users to make informed decisions regarding process optimization and control.

- Maintenance and Troubleshooting: Periodic maintenance of ultrasonic flow meters, including cleaning the transducers and verifying their alignment, is essential for sustained accuracy and performance. In case of any issues or discrepancies in the measurements, troubleshooting procedures can be implemented to diagnose and rectify the problem.

By following these guidelines, operators can effectively utilize ultrasonic flow meters to monitor and control fluid flow in diverse industrial and commercial settings.

Ultrasonic flow meter installation steps

1. Observe whether the pipeline at the installation site meets the distance from the front 10D to the front 5D and the distance from the pump 30D. (D is the inner diameter of the pipeline)

2. Confirm the fluid medium in the pipeline and whether it is full.

3. Confirm the pipe material and wall thickness (consider the thickness of the inner wall of the pipe

4. Confirm the service life of the pipeline. Even if the pipeline is about 10 years old, even if it is made of carbon steel, it is best to use plug-in installation.

5. After completing the first four steps, you can confirm which sensor to use

6. Start to input parameters to the watch body to determine the installation distance.

7. Very important: accurately measure the installation distance.Approximate installation distance of external clamp-type installation sensor, and then continuously adjust the active sensor to achieve the best match between signal and transmission ratio.Insert a special tool to measure the distance of the installation point on the pipe. This distance is very important. It directly affects the actual measurement accuracy of the meter, so it is best to perform multiple measurements to obtain higher accuracy.8. Install the sensor-debug signal-make waterproof-reorganize the signal cable-clean up the waste at the site-end of installation-acceptance signature

Ultrasonic Flow Meter installation

Z method installation: The general Z installation method is used on pipelines over 100mm, also known as the direct method V method installation: The V method is more commonly used for sensor installation. It is generally recommended to be used on pipes with a diameter of 20~300mm, also known as reflective hair.

W method installation: W method installation is usually used for DN10~100 pipeline flow measurement

Common problems in the use of ultrasonic flowmeter:

When the ultrasonic flowmeter probe is used for a period of time, an irregular alarm will appear. This problem is more common especially when there are many impurities in the conveying medium.Solution: Clean the probe regularly (it is recommended to clean it once a year. When the ultrasonic flowmeter transport medium contains water and other liquid impurities, the pressure tube of the flowmeter is prone to effusion, and the freezing of the pressure tube will occur when the temperature is low, especially in winter in the northern region.Solution: purge the pressure tube or apply heat. During the propagation of ultrasonic waves, due to the obstruction or absorption of the medium and impurities in the medium, its intensity will be attenuated. Regardless of whether it is an ultrasonic flowmeter or an ultrasonic level meter, there are certain requirements for the received sound wave intensity, so all kinds of attenuation must be suppressed.

Factors to Consider When Selecting an Ultrasonic Flow Meter

When choosing an ultrasonic flow meter for a specific application, several factors should be taken into consideration to ensure the suitability and performance of the device.

- Fluid Characteristics: Understanding the properties of the fluid to be measured, including its viscosity, temperature, and potential for aeration or particulate content, is essential for selecting the appropriate type of ultrasonic flow meter. Different fluid conditions may require specific ultrasonic technologies to achieve accurate flow measurement.

- Pipe Material and Diameter: The material and diameter of the pipe where the flow meter will be installed influence the selection of ultrasonic transducers and the compatibility of the meter with the piping infrastructure. Ensuring compatibility with the pipe material and size is crucial for effective installation and reliable operation.

- Flow Range and Accuracy Requirements: Determining the expected flow rate range and the desired level of measurement accuracy helps in selecting an ultrasonic flow meter with suitable capabilities. Different types of ultrasonic flow meters may offer varying measurement ranges and accuracy specifications to meet specific application needs.

- Environmental Conditions: Considering the environmental factors such as temperature extremes, humidity, and potential exposure to chemicals or abrasive substances helps in choosing an ultrasonic flow meter with robust construction and protective features. The device should be capable of withstanding the operational conditions within the application environment.

- Integration and Communication: Assessing the integration capabilities of the ultrasonic flow meter with existing control systems, data acquisition platforms, and communication protocols is crucial for seamless implementation and data accessibility. Compatibility with industry-standard communication interfaces and software platforms enhances the usability of the flow meter in diverse applications.

By evaluating these factors and consulting with experienced flow measurement professionals, users can make informed decisions when selecting an ultrasonic flow meter that aligns with their specific application requirements.

Conclusion

Ultrasonic flow meters have revolutionized flow measurement by offering non-intrusive, accurate, and versatile solutions for a wide range of applications. Understanding the inner workings, types, advantages, applications, and selection considerations of ultrasonic flow meters provides valuable insights for users seeking to leverage this advanced technology for flow monitoring and control.

By embracing the capabilities of ultrasonic flow meters and following best practices for installation, maintenance, and utilization, industries can benefit from enhanced operational efficiency, resource management, and compliance with regulatory standards. The continuous evolution of ultrasonic flow meter technology underscores its significance in modern industrial and commercial processes, making it an indispensable tool for optimizing fluid flow management and contributing to sustainable operations.

As industries continue to prioritize efficient and reliable flow measurement, the comprehensive understanding of ultrasonic flow meters presented in this article serves as a foundation for harnessing the full potential of this advanced technology. With the ability to adapt to diverse fluid conditions, provide accurate measurements, and minimize installation and maintenance efforts, ultrasonic flow meters stand as a testament to innovation and progress in the field of flow measurement and control.